Introduction

Recycling tires is a significant challenge that requires specialized equipment designed to handle the tough, durable nature of waste rubber. With millions of tires discarded annually, the importance of efficient tire recycling cannot be overstated. Rumroo, a global leader in tire shredding technology, offers innovative solutions that not only make tire recycling easier but also maximize the value of the end products. In this article, we’ll delve into how Rumroo’s tire shredders are specifically designed to recycle tires and the unique advantages they offer.

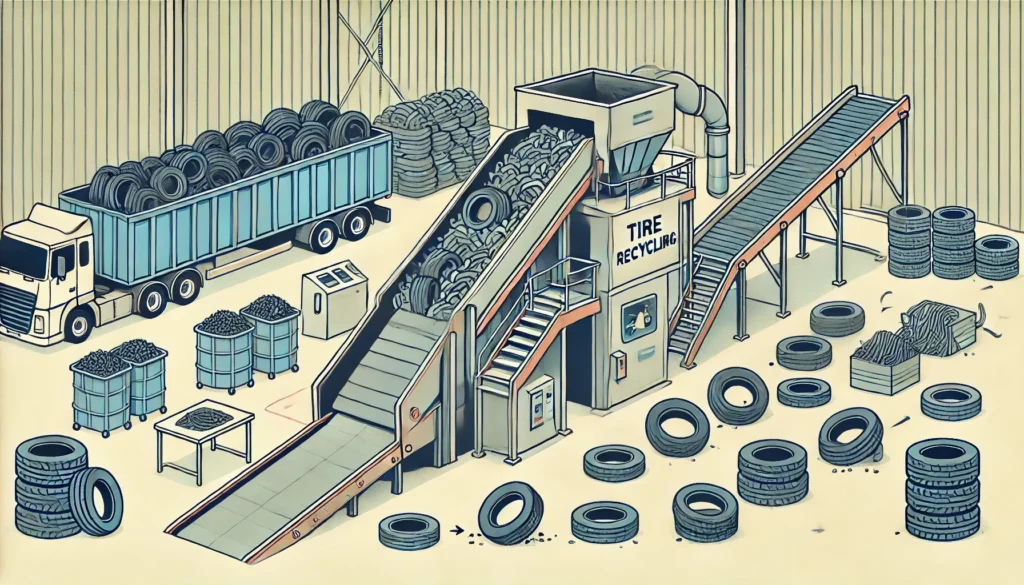

Tire Shredders: The Backbone of Tire Recycling

Rumroo’s tire shredders are engineered to tackle the toughest tire recycling tasks. These machines are essential in transforming discarded tires into valuable materials, such as clean rubber chips and tire-derived fuel (TDF). The robustness of Rumroo’s tire shredders lies in their ability to separate clean rubber from steel wire, a process that is crucial for producing high-quality recycled products.

Why Tire Shredders Are Essential

Tire shredders are at the heart of any tire recycling operation. They reduce the size of the tires, enabling further processing and ensuring that the rubber can be reused in various applications. The process starts with pre-shredding, where tires are broken down into smaller, more manageable pieces. Rumroo’s shredders are particularly effective here, as they can handle a wide variety of tire types, including those with steel belting.

Rumroo RTR Tire Re-Shredding Machines

One of Rumroo’s standout offerings is the RTR tire re-shredding machine. This machine is designed to re-shred pre-processed tires, delivering two distinct products: clean rubber and clean wire. The RTR machine is especially valuable for operations that require the production of tire-derived fuel or high-quality recycled rubber.

Advantages of Rumroo RTR Machines

- Dual Product Output: Rumroo’s RTR machines are unique in their ability to generate two end products – clean rubber and clean wire – simultaneously. This dual output increases the efficiency of the recycling process and adds value to the operation.

- Low Operating Costs: The RTR machines are engineered to have the lowest operating cost per ton of processed material in the industry. This efficiency translates into significant cost savings over time.

- Versatility: These re-shredders can handle a variety of tire types, from car and truck tires to industrial tires, making them versatile and reliable for different recycling needs.

The Importance of Clean Rubber Processing

Producing clean rubber is critical for various applications, such as creating mulch, bedding products, or even new rubber products. Rumroo’s tire shredders are designed to remove contaminants, particularly steel wire, from the rubber during the shredding process. This results in a high-quality rubber product that is free from impurities and ready for use in a wide range of industries.

Tire-Derived Fuel (TDF): A Sustainable Energy Source

Tire-derived fuel is an increasingly popular use for recycled tires. Rumroo’s shredders are particularly effective at producing TDF by ensuring that the rubber is clean and free from steel wire, making it a more desirable fuel source. TDF can be used in various industries, including cement manufacturing and power generation, as a cost-effective and environmentally friendly alternative to traditional fuels.

Rumroo: A Leader in Tire Recycling Technology

With over 40 years of experience in the industry, Rumroo has established itself as a leader in tire recycling technology. Their tire shredders are known for their durability, efficiency, and ability to produce high-quality end products. Whether you are looking to produce tire-derived fuel, clean rubber, or both, Rumroo offers the equipment and expertise you need to succeed.

Conclusion

Tire shredding is a crucial step in the tire recycling process, and Rumroo’s tire shredders stand out as some of the best in the industry. With the ability to produce clean rubber and TDF efficiently and cost-effectively, Rumroo’s equipment ensures that your tire recycling operation is both profitable and sustainable. If you’re serious about recycling tires, Rumroo’s tire shredders are the solution you’ve been looking for.

For more information on how to choose the right tire shredder for your recycling needs, check out our detailed guide on tire shredders.