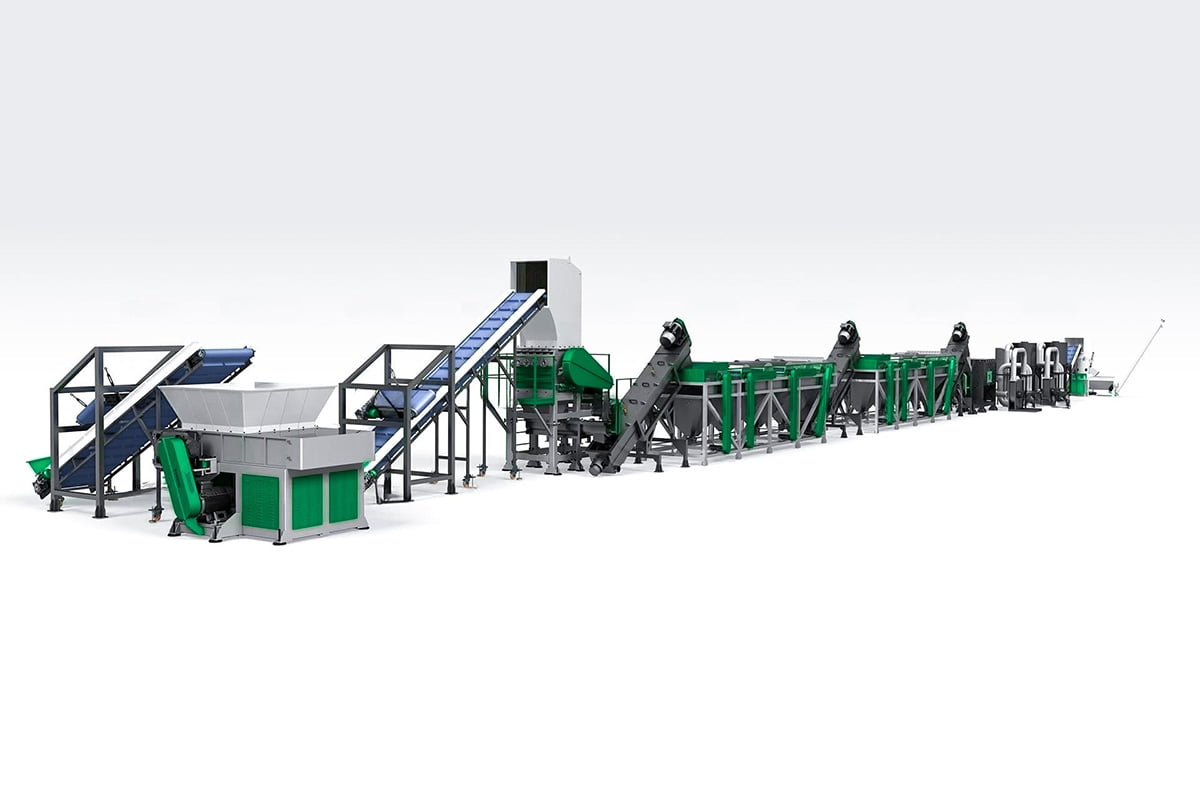

PP/PE Film Recycling Washing Line

A high‑efficiency PP/PE film recycling washing line engineered for flexible plastics—delivering clean, low‑moisture flakes ready for pelletizing.

Request a Customised ProposalWhy Choose Our PP/PE Film Washing Line?

Our technology is engineered for superior performance, efficiency, and reliability, ensuring you get the highest return on your investment.

High Purity Output

Achieve final product moisture levels below 3% with exceptional cleanliness, perfect for high-grade pelletizing.

Eco-Friendly Operation

Designed for reduced water and energy consumption, minimising your operational footprint and costs.

Robust & Versatile

Effectively processes a wide range of materials, from agricultural films to post-consumer woven bags.

Automated Process

Integrated control systems ensure seamless operation, reducing labour requirements and human error.

From Pain Points to Solutions

How our Plastic Washing Line turns challenges into reliable output.

Contaminants & Label Residue

Pain: Oils, adhesives, labels and dirt lower flake quality.

Solution: Intensive friction + hot washing achieves high cleanliness for pelletizing.

High Moisture & Low Bulk Density

Pain: Wet, fluffy film is hard to feed and costly to dry.

Solution: Film Squeezer & Dryer reduces moisture to ~1–3% and increases density for stable extrusion.

Unstable Throughput & Downtime

Pain: Frequent stoppages and variable input cause yield loss.

Solution: Modular line with PLC automation balances flow and simplifies maintenance.

High Water & Energy Costs

Pain: Inefficient loops waste resources and increase OPEX.

Solution: Optimised recirculation, filtration and energy‑saving settings cut utilities without sacrificing quality.

Processable Materials

Typical inputs include PE/PP films and flexible plastics. If you have mixed or unusual feedstock, we can evaluate it with a free trial.

LDPE/LLDPE Film

Post-consumer packaging, agricultural films.

PP Woven Bags

Bulk bags, sacks, and industrial packaging.

Artificial Grass

End-of-life turf from sports fields and landscaping.

PP Non-Woven Fabric

Shopping bags, agricultural covers, medical textiles.

PP/PE Film Washing Line vs Traditional Systems

A clear comparison to show where we add value across quality, efficiency, and operational stability.

| Criteria | Traditional Systems | Our Plastic Washing Line |

|---|---|---|

| Cleanliness | Basic rinse; residues often remain | Intensive friction + hot wash for high‑purity flakes |

| Final Moisture | 5–8% typical; extra drying needed | ~1–3% with Film Squeezer; ready for pelletizing |

| Water & Energy | Inefficient loops; higher OPEX | Optimised recirculation & energy‑saving settings |

| Automation | Manual adjustments; variable output | PLC control for stable throughput |

| Maintenance & Downtime | Frequent stoppages; harder to service | Modular design simplifies service & spares |

| Footprint & Layout | Fixed layouts; limited flexibility | Custom layouts to fit your space |

| Downstream Readiness | Often needs re‑drying/conditioning | Consistent flakes suitable for direct extrusion |

Plastic Washing Line Process: From Waste to Worth

Shredding & Granulation

Baled or loose plastics are shredded and then granulated into uniform flakes, preparing them for an effective washing process.

Intensive Hot & Friction Wash

High-speed friction washers and hot washing systems remove stubborn contaminants like oil, glue, and dirt.

Float-Sink Separation

Materials are separated based on density. Lighter plastics like PE/PP float, while heavier contaminants and plastics sink.

Drying & Agglomerating

Our innovative film squeezer dewaters and densifies the material, achieving <3% moisture for direct pelletizing.

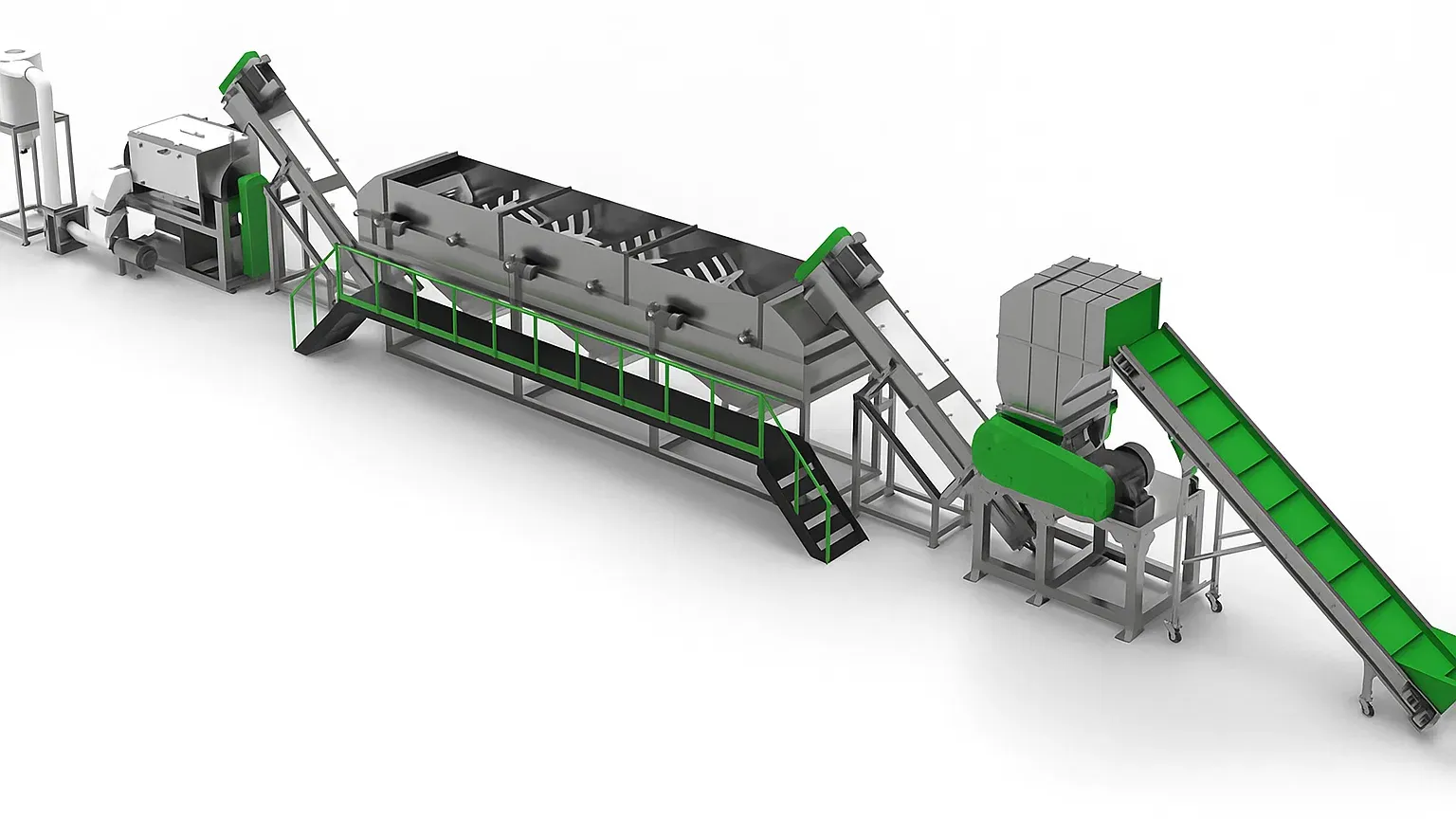

Engineered for Plastic Washing Performance

Explore the key components that make our recycling line a leader in the industry.

Single-Shaft Shredder

The first step in size reduction, our robust shredder efficiently processes baled or loose plastic films and bags, ensuring a consistent particle size for optimal washing.

- High-Torque Rotor: Powers through tough materials with minimal energy consumption.

- Durable Blades: Made from high-strength D2 alloy steel for extended life and performance.

- Hydraulic Pusher: Ensures continuous material feed to the rotor for maximum throughput.

Hot Washer System

Crucial for removing oils, glues, and stubborn organic contaminants. Our system uses heated water and optimised chemical agents to achieve a deep clean, significantly improving the quality of the final product.

- Integrated Heating: Eliminates the need for an external steam boiler, simplifying installation and operation.

- High-Speed Agitation: Ensures all flake surfaces are exposed to the cleaning solution.

- Automated Dosing: Precisely controls chemical additives for consistent and efficient cleaning.

Float-Sink Separation Tank

Separates materials by density after washing. PP/PE films and flakes float, while heavier contaminants (sand, stones, metals) sink—improving purity and protecting downstream equipment.

- Effective Density Separation: Reliable float/sink sorting for cleaner output.

- Stable Flow Design: Optimised water circulation improves separation efficiency.

- Easy Maintenance: Simple cleaning and durable construction for long service life.

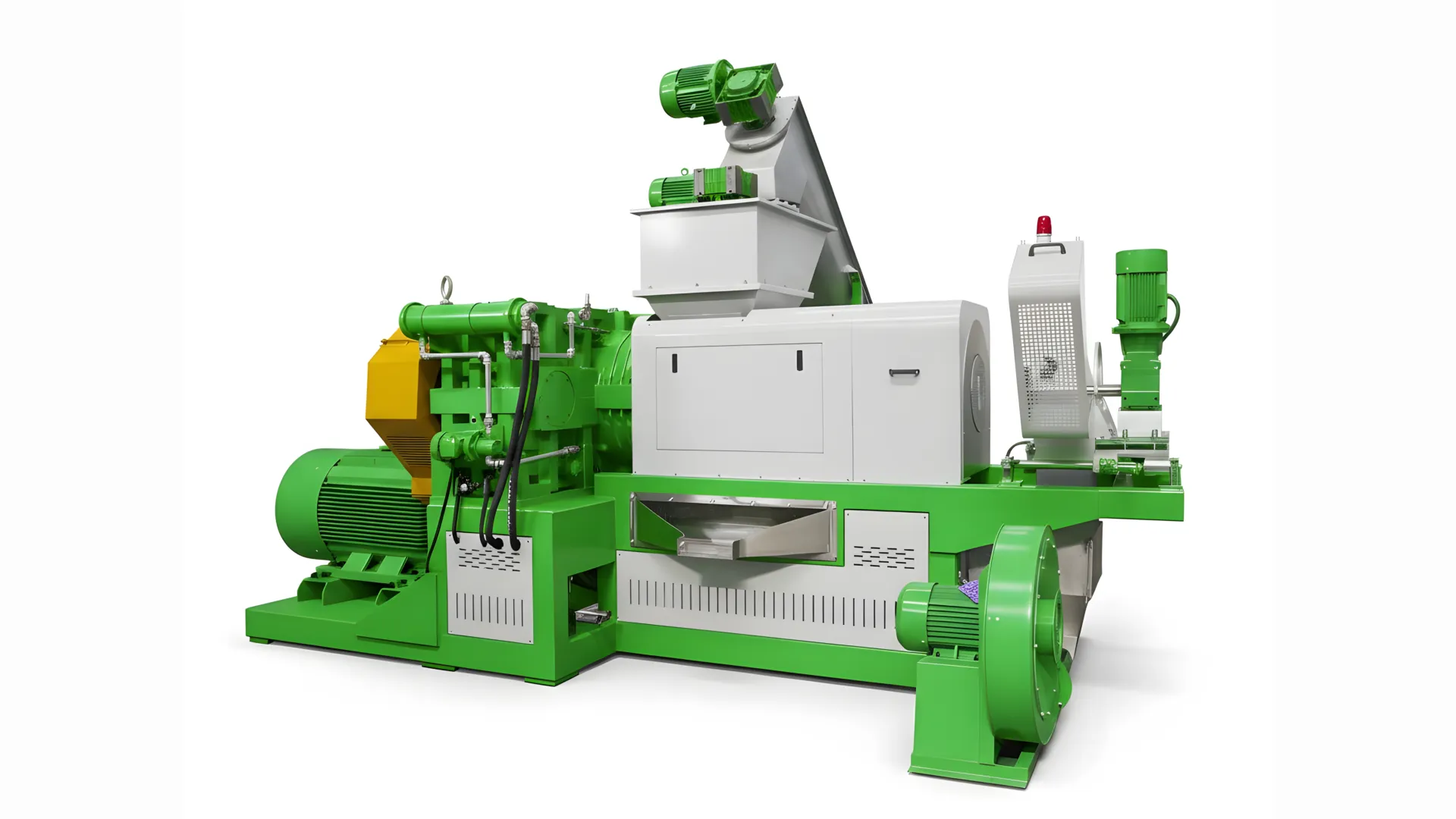

Film Squeezer & Dryer

A critical innovation that replaces traditional centrifugal and thermal dryers for film. This machine squeezes water out and uses frictional heat to semi-plasticise the material, resulting in dense, dry agglomerates with moisture below 2%.

- Superior Dewatering: Drastically reduces moisture, making it ideal for direct feeding into a pelletizer.

- Increases Bulk Density: Compacts fluffy film into dense particles, improving extruder feeding efficiency.

- Energy Efficient: Consumes significantly less energy compared to a combined dewatering and thermal drying setup.

Plastic Washing Line Specifications

| Parameter | Standard Configuration | Notes |

|---|---|---|

| Throughput Capacity | 300 - 2000 kg/hour | Customisable based on material and requirements. |

| Applicable Materials | PE/PP Film, Woven Bags, Non-Woven, Artificial Grass | Testing available for other materials. |

| Final Moisture Content | < 3% (with Film Squeezer) | Optimal for direct feed to pelletizing extruder. |

| Total Power Installed | Varies (e.g., ~250 kW for 500 kg/h line) | Line-specific; detailed in official quotation. |

| Control System | Centralised PLC with Touchscreen HMI | Siemens or equivalent components. |

See the Plastic Washing Line in Action

From dirty agricultural film to clean, valuable pellets. Witness the transformation in real production footage.

What Customers Say

Real feedback from teams running PP/PE film lines at scale.

The washing quality and moisture control are excellent. With the film squeezer we consistently hit 1–3%—pelletizing is far more stable now.

Plant Manager · Southeast Asia

Modular layout made installation straightforward. Operators like the PLC interface and we've seen fewer unplanned stoppages.

Operations Director · East Africa

Utility consumption is under control thanks to the recirculation setup. Overall OPEX is down versus our previous line.

Recycling Manager · Europe

Get Your Customised Solution & Quotation

Our team is ready to help you configure the perfect recycling line for your specific materials and output goals. Fill out the form below, and one of our specialists will be in touch shortly.

Plastic Washing Line FAQs

Find quick answers to common questions about our plastic film recycling line.

Our line is primarily designed for soft plastics like PE (Polyethylene) film, PP (Polypropylene) woven and non-woven bags, and agricultural films. It can be adapted for other materials like artificial grass. We recommend sending us a sample for a free trial to confirm compatibility and performance.

By using our advanced film squeezer, the final moisture content of the plastic agglomerates is typically below 3%, and often as low as 1-2%. This is ideal for high-quality pelletizing without requiring further drying, saving significant energy.

Yes, we provide a complete turnkey solution. This includes a detailed plant layout, on-site installation and commissioning by our experienced engineers, comprehensive training for your operational staff, and ongoing after-sales support, including spare parts and technical assistance.

The footprint varies depending on the capacity and specific components. For example, a 500 kg/h line might require a space of approximately 30 metres in length, 10 metres in width, and 6 metres in height. We will provide a detailed 2D/3D layout drawing as part of our proposal to ensure it fits perfectly within your facility.