High-Performance Plastic Pelletizing Lines for Uniform, High-Value Pellets

Our advanced plastic pelletizing lines are the final step in transforming recycled plastic waste into a valuable, consistent, and reusable raw material. We engineer complete systems for compounding, modifying, and pelletizing a wide range of polymers.

Design Your Pelletizing Line

Comparing Pelletizing Systems

The ideal technology depends on your material type, output requirements, and operational preferences. We specialize in two primary, highly efficient systems.

Water Strand Pelletizing Line

A classic, robust, and cost-effective method ideal for a wide variety of polymers, especially those sensitive to temperature changes.

- Process: Molten plastic is extruded into strands, cooled in a water bath, and then cut into pellets by a granulator.

- Best for: PET, Polystyrene (PS), and highly-filled or reinforced compounds.

- Advantage: Simple operation, easy to clean, and versatile for lab or large-scale production.

Water-Ring Pelletizing Line

A more automated and compact system that cuts pellets at the die face, ideal for high-volume production of polyolefins.

- Process: Blades rotate at the die face, cutting pellets which are instantly quenched and transported by a circulating water ring.

- Best for: PE, PP, and other materials with lower melt viscosity.

- Advantage: Produces uniform, spherical pellets, requires less floor space, and is highly automated.

Overcoming Production Challenges

How our pelletizing systems resolve common production challenges and improve quality, uptime, and cost.

Inconsistent pellet size and high fines

Closed‑loop control of die‑face/strand speed, automatic knife pressure, and post‑classification deliver uniform 3–5 mm pellets and lower dust/rework.

Frequent filter clogging and downtime

Continuous dual‑channel/backflush screen changers with enlarged filtration area extend run time, stabilize melt pressure, and cut scrap events.

Moisture/volatiles causing bubbles and poor surface

Pre‑drying plus vacuum‑vented extruders remove moisture and VOCs; optimized die heating produces a stable melt and glossy pellets.

High kWh/kg and water usage

IE3/IE4 motors with VFDs, energy‑tuned screws, and closed‑loop water circuits reduce specific energy consumption and utility costs.

Live System Demonstration

Watch a complete walkthrough of one of our advanced plastic pelletizing lines, from raw material to final, high-quality pellets.

Features for Consistent Quality

Every component is selected to ensure the purity, consistency, and value of your final product.

-

Continuous Melt Filtration

Automatic screen changers remove contaminants without interrupting production, ensuring a pure melt stream.

-

Efficient Dewatering

A vertical centrifugal dryer rapidly removes surface water from the pellets, preparing them for classification and storage.

-

Pellet Classification

A vibrating screen classifies pellets by size, removing oversized or undersized particles for a highly uniform final product.

-

Strand type cutting system

Water-cooled strands are cleanly cut into uniform pellets with low fines and consistent length.

Premium Output Applications

Our systems produce clean, uniform, and highly marketable pellets from a wide range of input materials.

PE Pellets

Plastic Film Pellets

PVC & Hard Plastic Pellets

Technical Specifications

Representative configurations. Custom engineering and options are available on request.

| Machine Model | Auxiliary Equipment | Single Screw Extruder | Capacity (kg/h) | |||

|---|---|---|---|---|---|---|

| Pelletizing Method | Filtering Method | Screw Diameter (mm) | L/D Ratio | Motor Power (kW) | ||

| SJ85–100 | Water strands pelletizing | Plate screen changer | 85 / 100 | 28–33:1 / 10:1 | 55–75 | 100–200 |

| SJ100–120 | Water strands pelletizing | Plate screen changer | 100 / 120 | 28–33:1 / 10:1 | 90–110 | 200–350 |

| SJ130–150 | Water strands pelletizing | Column screen changer | 130 / 150 | 28–33:1 / 10–12:1 | 132–160 | 400–550 |

| SJ150–160 | Water strands pelletizing | Column screen changer | 150 / 160 | 28–33:1 / 12:1 | 185–200 | 500–650 |

| SJ160–180 | Water ring pelletizing | Automatic screen changer | 160 / 180 | 28–33:1 / 12:1 | 220–250 | 700–900 |

| SJ180–200 | Water ring pelletizing | Automatic screen changer | 180 / 200 | 28–33:1 / 12:1 | 280–315 | 900–1200 |

Customer Success Outcomes

Real outcomes reported by customers operating our pelletizing systems.

Pellet quality tightened and dust dropped by about 40%, while throughput rose ~25% after moving to continuous filtration and tuning cutter speed.

Water‑ring pelletizing stabilized PP film regrind across shifts. Specific energy fell by roughly 15% and shift‑to‑shift variability was reduced.

Turnkey delivery and on‑site training were on schedule. Uptime improved with the recommended screen packs and maintenance plan.

Get Your Custom Quote

Contact our experts to discuss your specific material and application. We will design a custom pelletizing or compounding line to meet your goals for quality and throughput.

Get a Custom System QuoteFrequently Asked Questions

Strand pelletizing extrudes molten plastic into strands cooled in water before cutting, while water-ring pelletizing cuts at the die face, producing uniform spherical pellets. The best choice depends on polymer type and production scale.

PET, HDPE, LDPE, PP, PS, EVA, ABS, and filled or reinforced compounds. The systems can process both recycled and virgin materials.

Yes. We provide full pelletizing systems with extruders, filtration, pellet cutting, cooling, and drying, as well as installation and training.

Typical line capacities range from 100 to 2000 kg/h depending on configuration and polymer type.

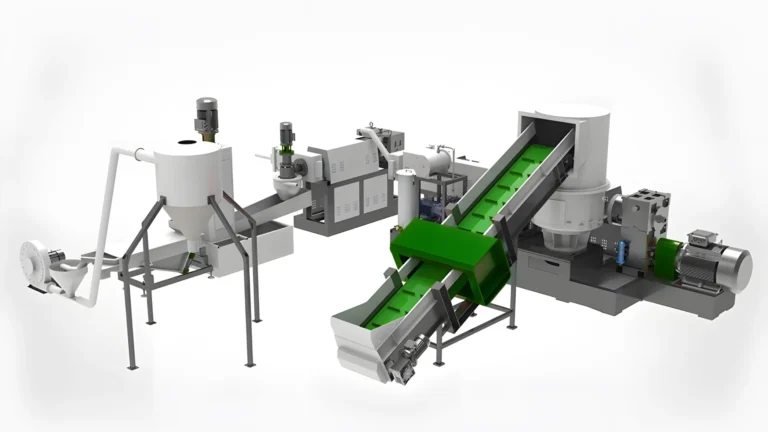

Cutter Compactor Pelletizing Line for PP/PE Films & Bags

Integrated system combining shredding, compacting, and pelletizing. Efficiently processes lightweight, fluffy materials like films and raffia without pre-shredding.

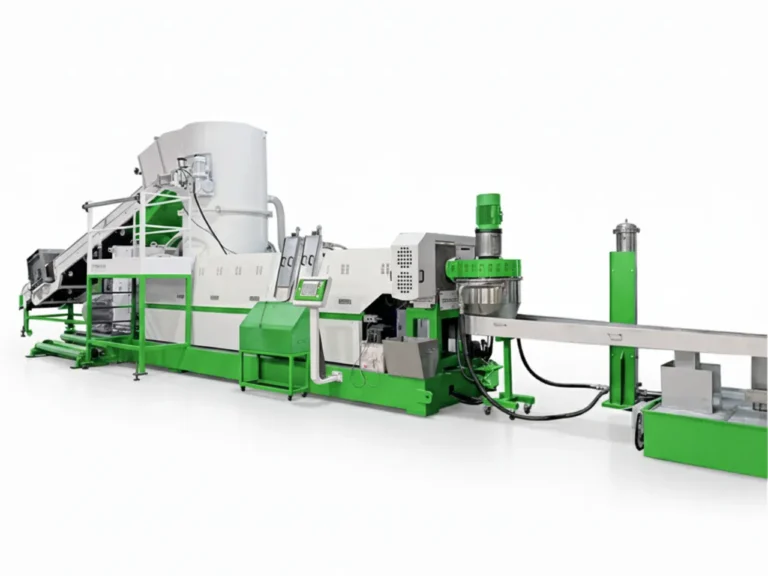

Water Ring Die-Face Pelletizing Line for PP/PE Film

Achieve uniform, spherical pellets with our Water Ring Die-Face Cutting System. Designed to eliminate strand breakage, ensuring stable production.

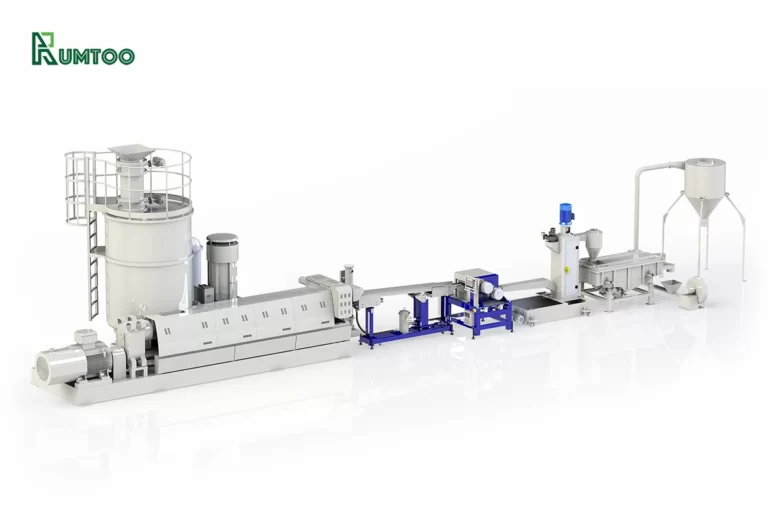

Standard Plastic Film Strand Pelletizing Line

Cost-effective strand pelletizing line designed for recycling clean PP/PE films and industrial regrinds. Features a water cooling bath for reliable operation.

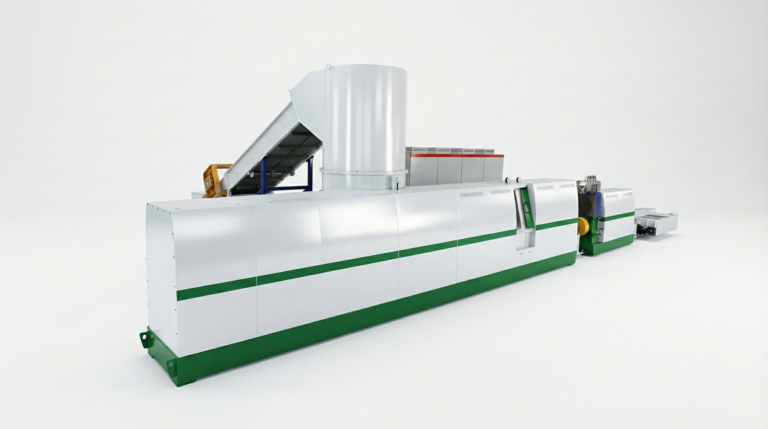

BOPP Film Cutter Compactor Pelletizing Line

Specialized for printed and metalized BOPP films. Features double-zone vacuum degassing to remove ink volatiles, ensuring bubble-free pellets.

Rigid PP/HDPE Two-Stage Pelletizing Line

Heavy-duty two-stage system designed for rigid PP/HDPE flakes. Excellent filtration and degassing capabilities make it perfect for contaminated waste.

Efficient EPS Foam Granulating Machine

Transform bulky Styrofoam waste into dense granules. This machine reduces volume significantly and turns EPS foam into valuable raw materials.

PET Bottle Flake Pelletizing Line (High Viscosity)

High-performance single screw extruder designed for PET bottle flakes. Ensures minimal IV drop and produces high-clarity pellets.

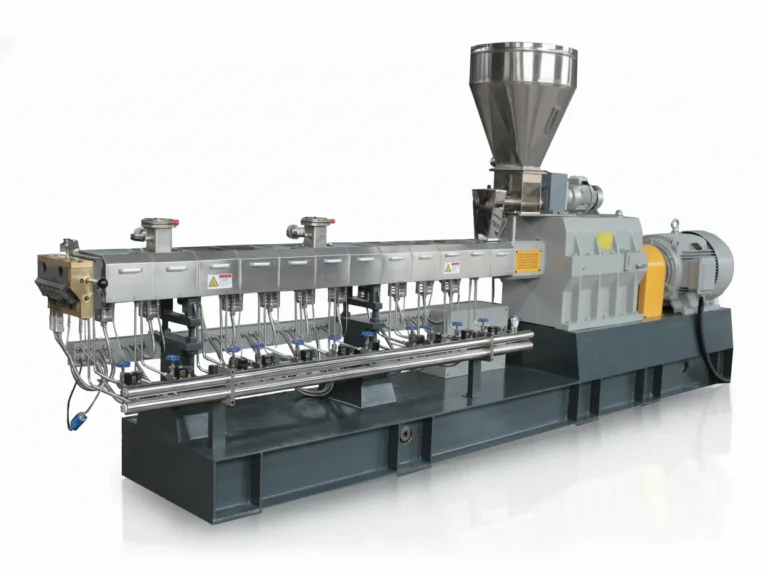

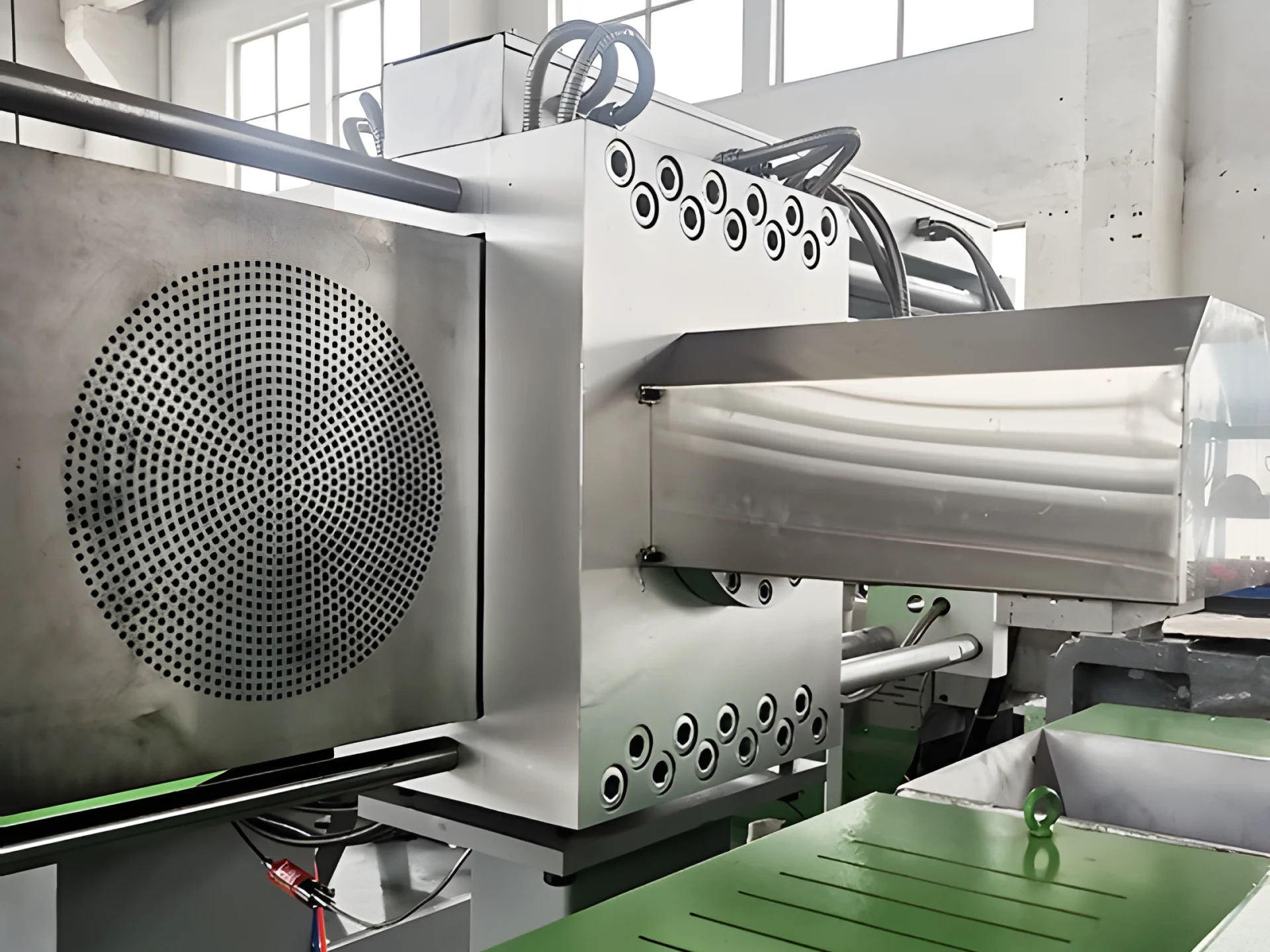

Twin Screw Compounding Extruder

Co-rotating twin screw extruder designed for plastic modification, masterbatch, and filler compounding. Precise temperature control for polymers.

Single-Screw Plastic Pelletizing Machine

Versatile single-screw extruder suitable for a wide range of thermoplastic recycling applications. Robust, reliable, and easy to operate.

High MFI PP Meltblown Recycling Pelletizing Machine

Specialized for recycling high MFI PP meltblown nonwovens. Features an integrated cutter compactor and water-ring pelletizing system to handle fluffy waste efficiently.

Laboratory twin-screw extruder

Compact twin-screw extruder designed for laboratory testing and small-batch production. Ideal for polymer research, color matching, and developing new formulations.