Our wet plastic bottle label remover is an innovative recycling machine capable of removing more than 95% of the labels from intact plastic bottles. As this machine utilizes water to detach the labels, the bottles are cleaned simultaneously, making this an excellent option to enhance your current or new PET bottle recycling operation.

This wet plastic bottle label remover transforms how PET plastic bottles are traditionally processed for recycling. The first step in most recycling operations involves feeding the intact plastic bottles into a plastic granulator without stripping the labels. This results in PET flakes that are mixed with shredded labels and bottle caps. Because it is more challenging to separate the plastics once they are combined, several machines are required.

Therefore, a more efficient method of processing PET bottles for recycling is to remove the labels first. With a single machine, the wet plastic label remover can eliminate more than 95% of plastic label contaminants from your PET flake output stream.

Even if you are currently shredding plastic bottles whole, adding this label remover will enhance the quality of your PET flakes and increase the capacity of your PET bottle washing line.

Working Principle

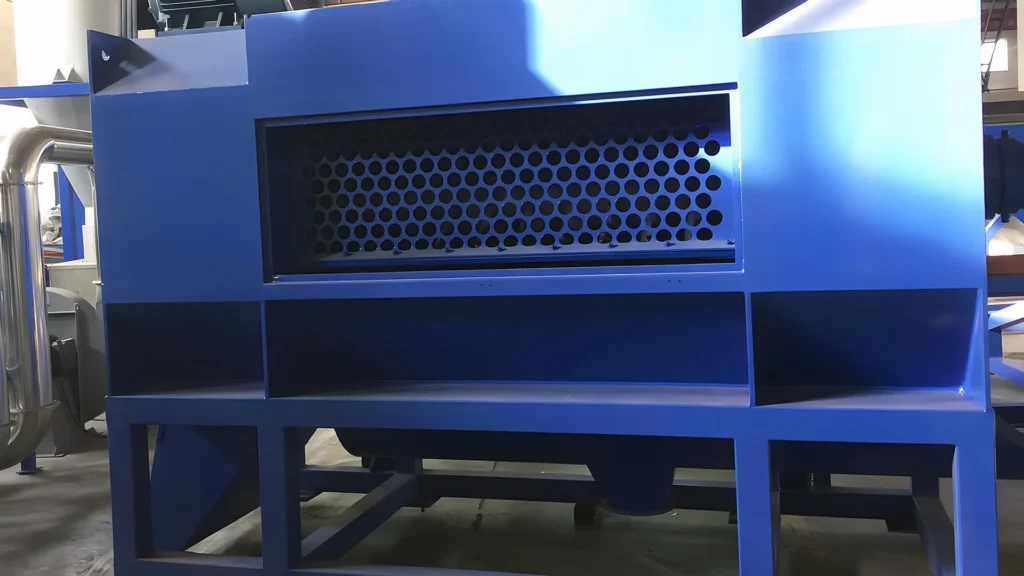

Inside the wet plastic bottle remover are durable, jagged knives that act like claws to cut and tear the labels away from the plastic bottles. These imported alloy knives are copper welded onto a moderately spinning rotor set at specific angles to move the bottles forward.

This machine operates similarly to our plastic bottle label remover, where the cut labels are blown into a collection chute. Instead of using air to blow the labels away, our wet label remover sprays the labels away using a stream of water. This not only removes the labels but also washes the bottles simultaneously.

To ensure the optimal performance of this machine, the knives will need to be occasionally removed, sharpened, and then replaced.

Additional Images

Warranty & Installation

Each recycling machine includes a 1-year limited warranty. We provide installation services, with our engineers visiting your site to assist with the setup process. Arrangements for regular maintenance crews and operational consultants can also be made.

Inquire Now

To get the latest prices and lead times, send us a message using the form below.