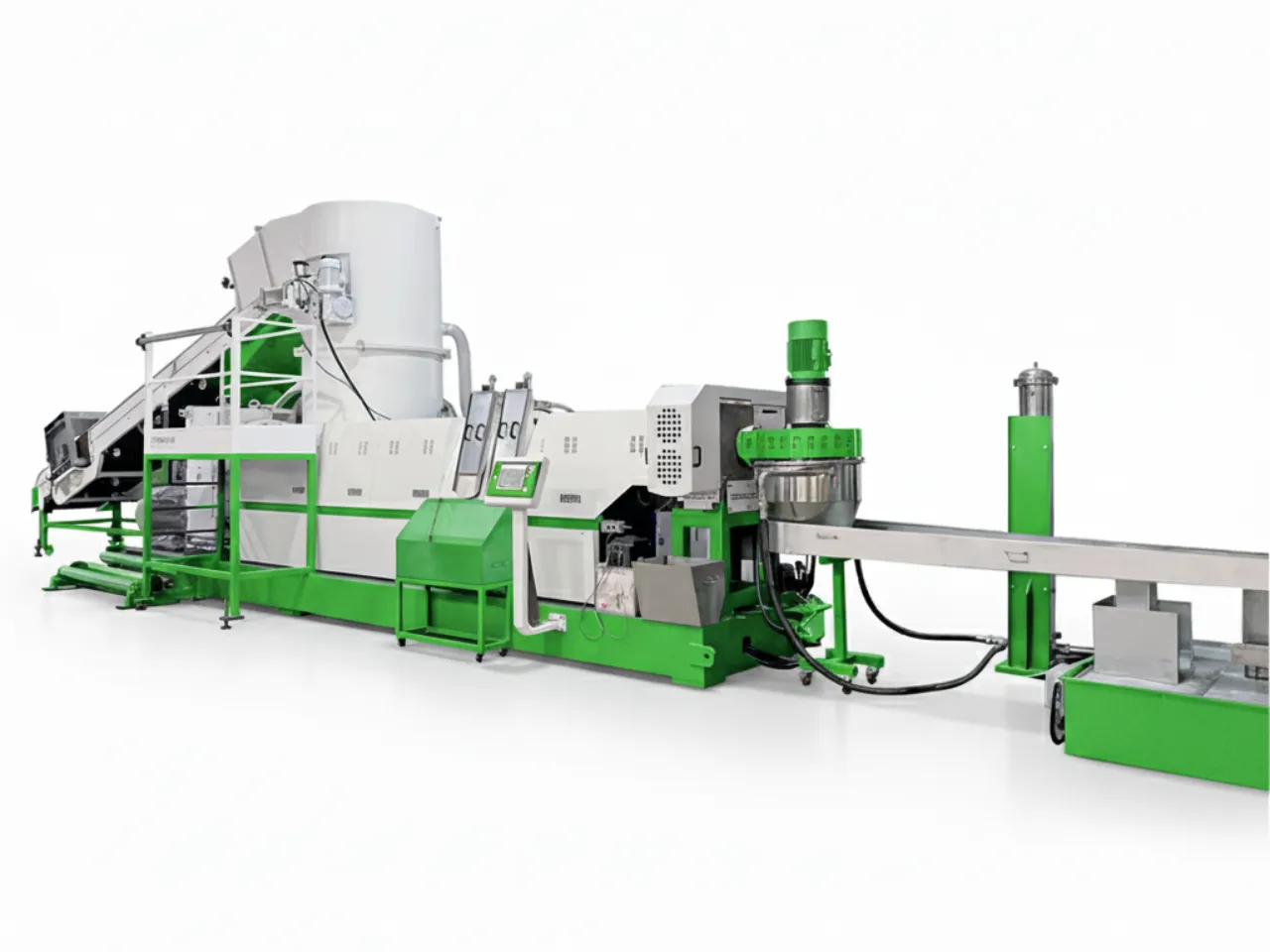

Water Ring Pelletizer: The Cure for Strand Breakage

Stop dealing with messy strands and downtime.

For PP/PE film recyclers, "strand breakage" is the #1 headache caused by moisture or MFI fluctuations. Our Water Ring Die-Face Cutter solves this permanently. It cuts molten plastic directly at the die head—ensuring continuous, automated production of uniform, round pellets without the need for manual restringing.

Why Upgrade to Water Ring Technology?

- Zero Strand Breakage

Unlike strand pelletizers, our die-face system has no strands to break. It handles fluctuating MFI and moisture without stopping, ensuring 100% uptime.

- Premium Pellet Aesthetics

Produces round, uniform "lentil-shaped" pellets that look professional and flow better in hoppers, commanding a higher market price.

- Fully Automated Operation

Say goodbye to operators standing by the water bath. One-button start means the machine runs itself, significantly reducing labor costs.

- Higher Moisture Tolerance

Steam pockets that snap strands are no issue here. The water ring system effectively cools and conveys pellets even with imperfectly dried input materials.

- Compact & Efficient

By eliminating the long water bath cooling tank, the water ring system saves valuable factory floor space.

- Consistent Throughput

The integrated cutter compactor ensures feeding stability, but the real star is the cutter that keeps up with high-speed production without interruption.

Working Principle: A 5-Stage Process

- 1. Feeding

Material is fed via a belt conveyor into the compactor. The feeding speed is automatically adjusted, and an optional metal detector can be integrated for protection.

- 2. Shredding & Compacting

Rotary blades cut and heat the material through friction, shrinking and densifying it before it's fed directly and stably into the extruder screw.

- 3. Plasticizing & Degassing

A specialized single-screw extruder gently melts the material. A double-zone vacuum system then efficiently removes inks, moisture, and other volatiles.

- 4. Water Ring Pelletizing

The core advantage: Molten plastic is cut immediately upon exiting the die head and flung into a cooling water ring. No strands, no breakage, just perfect pellets.

Typical Applications

- Flexible Packaging

Perfect for LDPE/LLDPE industrial films, shopping bags, and shrink wraps.

- PP Woven Bags

Handles raffia, cement bags, and bulk bags (FIBC) with high strength and consistency.

- Multi-Layer Films

Efficiently processes complex films including printed or laminated BOPP materials.

- Post-Consumer Waste

Robust enough to handle washed agricultural films and post-consumer plastic scraps.

Technical Specifications

| Model | Screw Dia. (mm) | L/D Ratio | Main Motor (KW) | Throughput (kg/h) |

|---|---|---|---|---|

| RM80 | 80 | 36:1 | 45/55 | 160-220 |

| RM100 | 100 | 36:1 | 90/110 | 300-380 |

| RM120 | 120 | 36:1 | 132 | 450-480 |

| RM140 | 140 | 36:1 | 160/185 | 500-650 |

| RM160 | 160 | 34:1 | 220/250 | 800-1000 |

| RM180 | 180 | 34:1 | 315 | 1000-1200 |

See It In Action

@chat_machine PP PE plastic pelletizing machine #plasticpelletmachine #pelletizingmachine #recyclingmachine ♬ original sound - Rumtoo Recycling Machinery

Warranty & Installation

- 1-Year Limited Warranty

All our recycling machinery comes with a limited warranty, ensuring peace of mind with your purchase.

- Expert Installation Support

We offer installation packages where our engineers can travel to your facility to guide you through the setup process. All our products can be customized to customer requirements.

Inquire Now

Ready to eliminate strand breakage and upgrade to professional-grade pellets? Contact us for a quote on our Water Ring system.