In our daily lives, plastics play an indispensable role due to their versatility and durability. However, the widespread use of plastics poses significant environmental challenges. Understanding the types of plastics, their applications, and how they can be recycled is crucial for reducing this impact. As a manufacturer of recycling equipment, we are committed to improving plastic recycling rates and minimizing environmental footprints. This guide provides a detailed overview of the various types of plastics, their common uses, characteristics, and recycling processes to help our customers engage more effectively in recycling efforts.

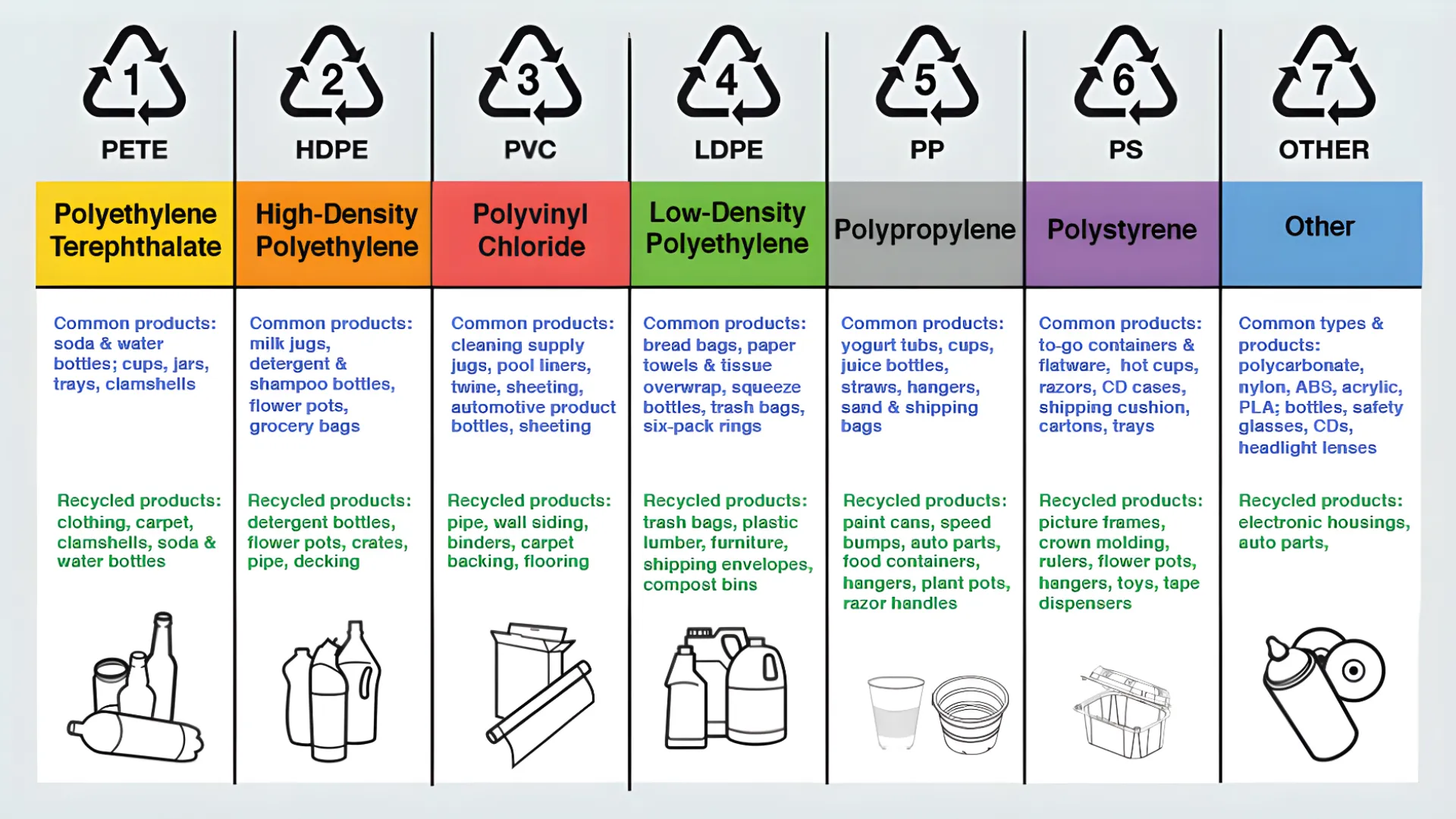

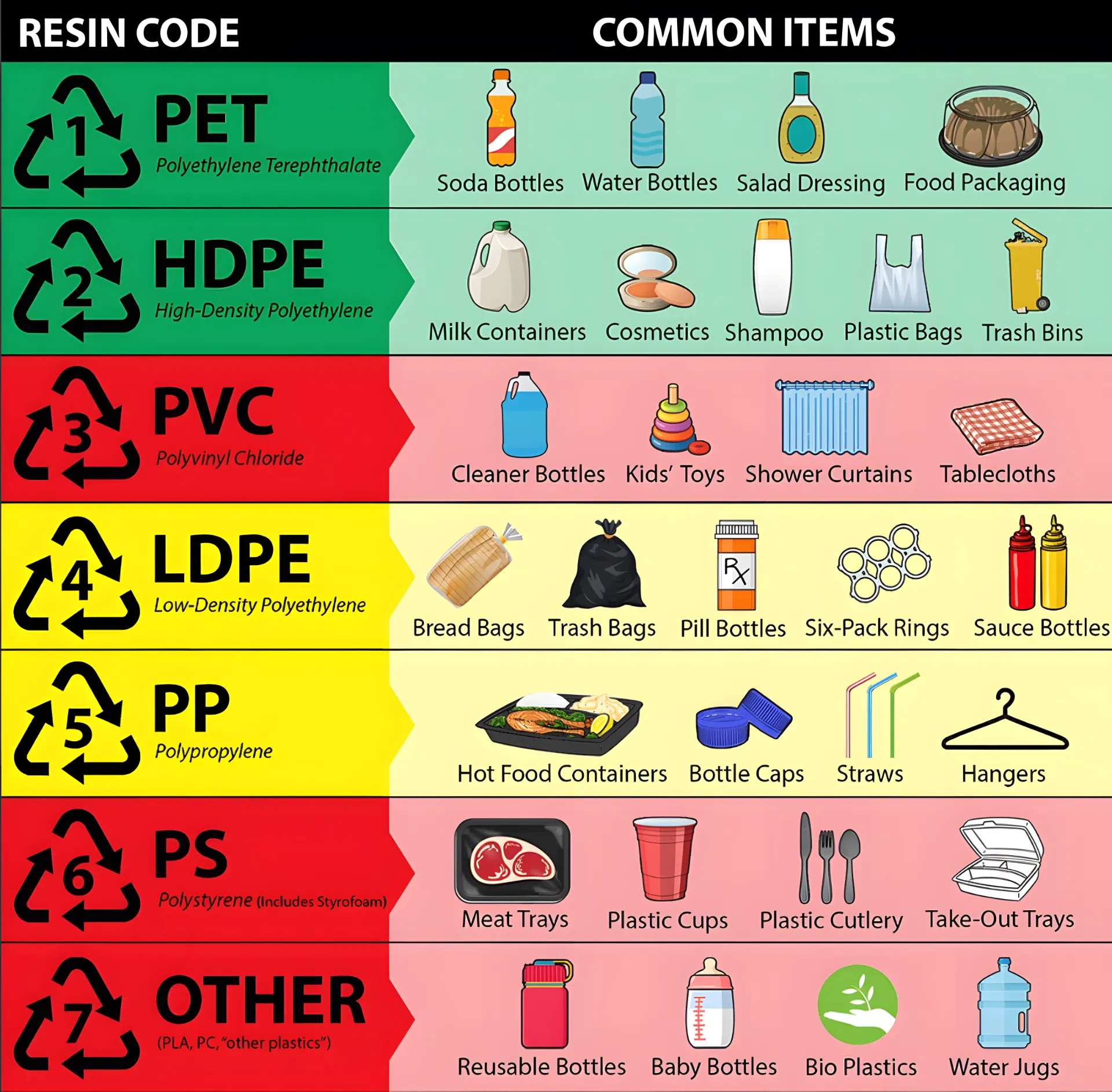

The ASTM International Resin Identification Coding System (RIC) is a set of symbols on plastic products that identify the type of plastic resin used. Developed in 1988 by the Society of the Plastics Industry (now the Plastics Industry Association) in the United States, it has been administered by ASTM International since 2008.

Because RIC symbols resemble recycling symbols, they are often confused with them. Recent revisions to the RIC have replaced the arrows with a solid triangle, but older symbols remain widely used.

1. PET (Polyethylene Terephthalate) — Resin Identification Code 1

Common Uses: Water bottles, soda bottles, and juice containers.

Characteristics: Highly transparent, strong, and flexible, with good resistance to water and oxygen permeation.

Recycling Performance: PET is highly recyclable and can be transformed into polyester fibers, filling materials for pillows, and more.

2. HDPE (High-Density Polyethylene) — Resin Identification Code 2

Common Uses: Milk jugs, detergent bottles, and trash bins.

Characteristics: High strength, good temperature resistance, and strong chemical resistance.

Recycling Performance: Recycled HDPE is used to manufacture plastic lumber, containers, and pipes.

3. PVC (Polyvinyl Chloride) — Resin Identification Code 3

Common Uses: Pipes, window frames, and insulation for electrical wires.

Characteristics: Hard and chemically resistant, but releases harmful compounds during processing.

Recycling Performance: PVC recycling is challenging; it is often repurposed into flooring or other construction materials.

4. LDPE (Low-Density Polyethylene) — Resin Identification Code 4

Common Uses: Plastic bags, frozen food packaging, and plastic wrap.

Characteristics: Flexible and transparent but poor temperature resistance.

Recycling Performance: LDPE is relatively easy to recycle and is often used to produce trash bags and composite lumber.

5. PP (Polypropylene) — Resin Identification Code 5

Common Uses: Food containers, microwave ovenware, and automotive parts.

Characteristics: High thermal resistance, hardness, and good chemical resistance.

Recycling Performance: Recycled PP is often used in producing garden planters, storage containers, and household goods.

6. PS (Polystyrene) — Resin Identification Code 6

Common Uses: Disposable cutlery, CD cases, and insulation.

Characteristics: Low cost, lightweight, but brittle and difficult to degrade.

Recycling Performance: PS is less commonly recycled but can be reprocessed into insulation materials and other products.

7. Other — Resin Identification Code 7

Common Uses: A variety of plastic products including multi-layer composites and electronics casings.

Characteristics: This category includes various plastics with diverse properties.

Recycling Performance: Plastics labeled with code 7 are the most difficult to recycle and often require specialized processing technologies.

Conclusion

By understanding the different types of plastics and their respective recycling processes, industry professionals can make informed decisions that contribute to more effective recycling practices. Our commitment as a recycling equipment manufacturer is not only to provide solutions that enhance recycling rates but also to educate and engage our customers in meaningful environmental stewardship. Together, we can reduce the ecological impacts of plastic waste and promote a more sustainable future.