In today’s fast-paced world, where data security is a top priority, industrial shredders have become an essential tool for businesses across industries. Whether you’re looking to dispose of sensitive documents, shred plastic waste, or destroy electronic media, choosing the right industrial shredder is crucial to ensure efficient and effective material processing. With a wide range of options available in the market, it can be overwhelming to navigate through the choices and determine the perfect shredder for your needs. This comprehensive guide aims to demystify the selection process, equipping you with the knowledge needed to make an informed decision.

The World of Industrial Shredders Unveiled

Understanding the Material Processing Capabilities of Industrial Shredders

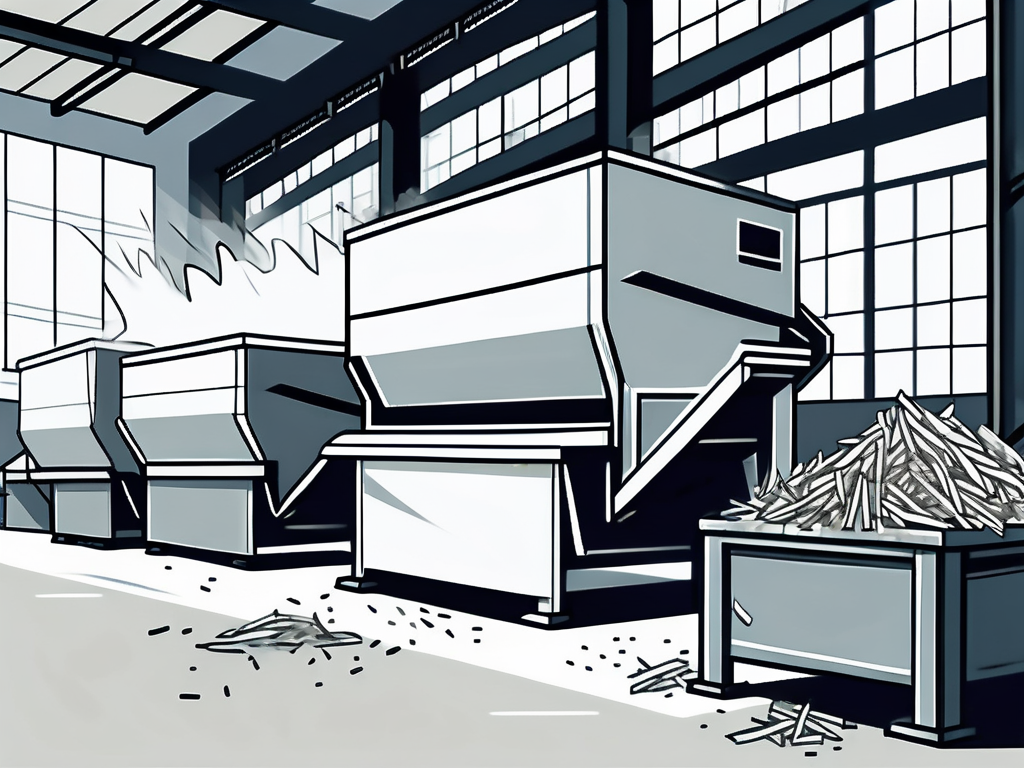

Industrial shredders are powerful machines designed to break down various materials into smaller, more manageable pieces. From paper and cardboard to metal and plastic, these shredders can handle a wide range of materials, making them versatile solutions for different applications. But what exactly are the material processing capabilities of industrial shredders?

When it comes to paper and cardboard, industrial shredders can effortlessly reduce them into fine strips or confetti-like pieces, ensuring secure disposal or recycling. For metal materials, these machines can effectively shred them into smaller chunks or even turn them into scrap metal, which can be further processed for recycling or repurposing. As for plastic, industrial shredders can transform it into small flakes or granules, making it easier to recycle or reuse in various manufacturing processes.

When it comes to paper and cardboard, industrial shredders can effortlessly reduce them into fine strips or confetti-like pieces, ensuring secure disposal or recycling. For metal materials, these machines can effectively shred them into smaller chunks or even turn them into scrap metal, which can be further processed for recycling or repurposing. As for plastic, industrial shredders can transform it into small flakes or granules, making it easier to recycle or reuse in various manufacturing processes.

Decoding Output Options for Industrial Shredders

Once materials are shredded, they need to be processed further depending on your specific requirements. Industrial shredders offer different output options, including granulating, mulching, or baling. Granulating involves further reducing the shredded materials into even smaller particles, which can be used as raw materials in other industries. Mulching, on the other hand, involves turning the shredded materials into a nutrient-rich mulch that can be used for landscaping or gardening purposes. Lastly, baling compresses the shredded materials into compact bales, making them easier to store, transport, or sell to recycling facilities.

Determining the Ideal Capacity for Your Industrial Shredder

The capacity of an industrial shredder refers to its ability to process a certain volume of materials within a given time frame. Understanding your average shredding needs and estimating the required capacity will help you select a shredder that can handle your workload efficiently and prevent any bottlenecks in your operations. Whether you have a small-scale shredding operation or a large-scale industrial facility, there are shredders available with varying capacities to suit your specific requirements.

Navigating Different Feed Types in Industrial Shredders

Industrial shredders offer various feed types, including manual feed, gravity feed, and conveyor feed systems. Each feed type has its own advantages and considerations. Manual feed allows for more control and flexibility, as operators can feed materials at their own pace. Gravity feed systems, on the other hand, use the force of gravity to feed materials into the shredder, which can be ideal for continuous shredding operations. Conveyor feed systems automate the feeding process, allowing for higher throughput and increased efficiency. Considering factors such as ease of use, material handling efficiency, and operator safety will assist you in making the right choice for your specific needs.

Key Operational Factors to Consider When Choosing a Shredder

Aside from material processing capabilities and feed types, there are several key operational factors to consider when selecting an industrial shredder. These include power requirements, maintenance needs, noise levels, and safety features. Industrial shredders come in different sizes and power options, so it’s important to choose one that matches your available power supply and energy consumption goals. Maintenance needs vary depending on the shredder’s design and complexity, so it’s crucial to assess your maintenance capabilities and schedule to ensure optimal performance. Noise levels should also be taken into account, especially if the shredder will be operating in a noise-sensitive environment. Lastly, safety features such as emergency stop buttons, safety guards, and automatic shut-off systems should be thoroughly evaluated to ensure the well-being of operators and prevent accidents.

The Importance of Proper Maintenance for Industrial Shredders

Proper maintenance is crucial to keeping your industrial shredder in optimum condition and prolonging its lifespan. Regular cleaning, lubrication, and inspection are essential maintenance practices that can enhance performance, prevent breakdowns, and ensure safe operation. Additionally, following manufacturer-recommended maintenance schedules and procedures will help identify and address potential issues before they escalate. Implementing a proactive maintenance routine will save you time, money, and potential downtime in the long run, ensuring that your industrial shredder continues to operate efficiently and effectively.

Demystifying the Selection Process for Shredders

Common Applications of Industrial Shredders Across Industries

Industrial shredders find applications across a wide range of industries, including financial institutions, government organizations, manufacturing facilities, recycling plants, and more. Understanding the common applications can help you identify the specific shredder features and capabilities that are most relevant to your industry.

Essential Criteria for Choosing the Right Industrial Shredder

When selecting an industrial shredder, it is important to assess several criteria, including shredder type, security level, shredding speed, and cost-effectiveness. Considering these essential criteria will enable you to narrow down your options and find the perfect shredder that meets your specific requirements while staying within your budget.

A Quick Recap: Selecting the Perfect Shredder for Your Needs

In conclusion, choosing the right industrial shredder is a critical decision that can affect the efficiency, productivity, and security of your operations. By understanding the material processing capabilities, output options, capacity requirements, and feed types, as well as considering key operational factors such as maintenance and safety, you can make an informed decision that aligns with your industry’s needs. Remember to factor in the common applications of industrial shredders and the essential criteria for making the right choice. With this ultimate guide, you are now equipped to select the perfect shredder for your needs with confidence.

Let’s delve deeper into the common applications of industrial shredders. Financial institutions, for example, rely on shredders to securely dispose of sensitive documents containing confidential customer information. These shredders are designed to meet high-security standards and ensure that no trace of the shredded documents can be reconstructed.

Government organizations also heavily rely on industrial shredders to safeguard classified information. These shredders are equipped with advanced security features, such as cross-cut shredding technology, which ensures that the shredded materials are virtually impossible to piece back together.