Plastic recycling has become increasingly important in today’s world as we strive towards a more sustainable future. One key aspect of plastic recycling is the process of pelletizing, which involves transforming plastic flakes into pellets that can be used to create new products. In this article, we will explore the top plastic pelletizer machines for PET flakes recycling, delving into the advanced technologies and innovative solutions that are available in the market. Sustainability is at the forefront of these advancements, ensuring that plastic recycling becomes more efficient and environmentally friendly.

Advanced Plastic Recycling Technologies

As the demand for plastic recycling increases, so does the need for more advanced plastic recycling technologies. These technologies aim to improve the efficiency and effectiveness of the recycling process, ultimately reducing the amount of waste that ends up in landfills and oceans.

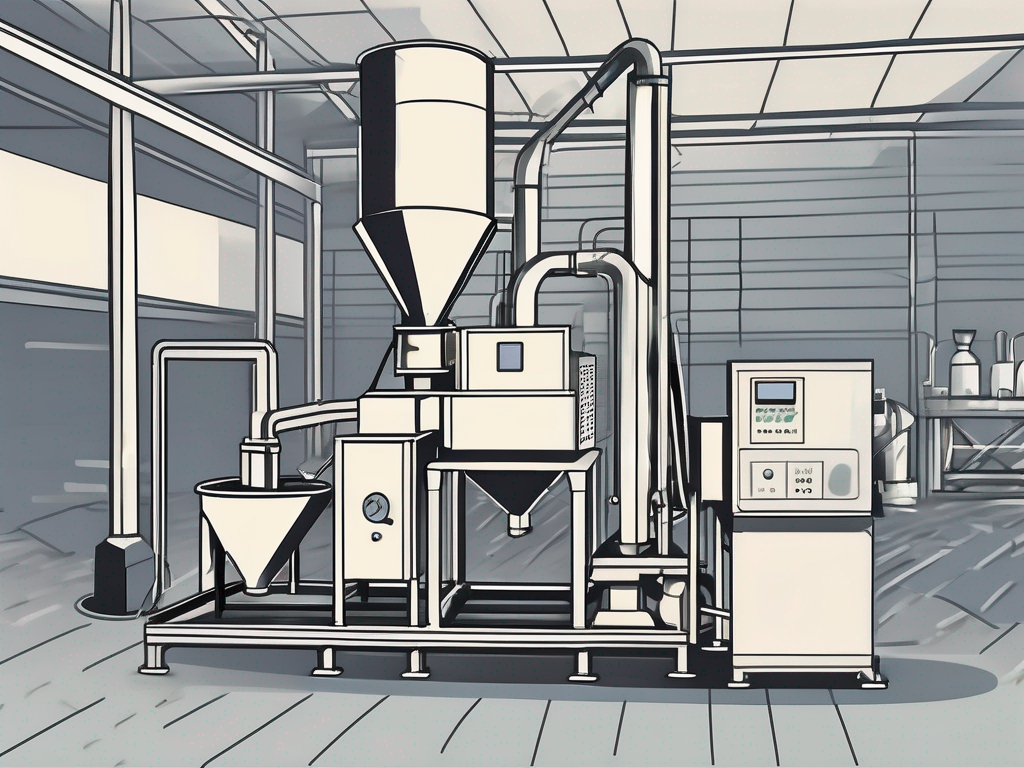

One such technology is the plastic pelletizer machine. These machines play a crucial role in the recycling process by transforming plastic flakes into uniform pellets that can be easily used in the production of new plastic products. They allow for better control over the size and shape of the pellets, ensuring high quality and consistency.

But what are some of the different types of plastic recycling machinery available in the market? Let’s explore.

Different Types of Plastic Recycling Machinery

There are various types of plastic recycling machinery available in the market, each designed to suit different recycling needs.

One popular type is the strand pelletizer. This machine uses a cutting rotor to slice plastic strands into pellets. It is efficient and versatile, making it suitable for a wide range of plastic materials. With its precise cutting mechanism, it ensures that the pellets are of consistent size and shape, meeting the stringent requirements of manufacturers.

Another type is the underwater pelletizer. As the name suggests, this machine operates underwater, offering unique advantages such as increased cooling efficiency and reduced waste generation. The underwater environment allows for rapid cooling of the plastic, resulting in pellets with excellent physical properties. This technology is particularly well-suited for processing heat-sensitive plastics.

Additionally, there are also centrifugal pelletizers, which rely on centrifugal force to transform plastic flakes into pellets. These machines are known for their high production capacity and ability to process a wide range of plastic materials. The centrifugal force generated by the machine ensures that the plastic is evenly distributed, leading to uniform pellets with minimal waste.

As the plastic recycling industry continues to evolve, innovations in plastic recycling solutions are driving the industry forward, making the recycling process more efficient and sustainable.

Innovations in Plastic Recycling Solutions

Innovations in plastic recycling solutions continue to drive the industry forward, making the recycling process more efficient and sustainable.

RUMTOO, a leading company in the field of plastic recycling, is revolutionizing the industry with its cutting-edge solutions. They offer a range of advanced plastic pelletizer machines that incorporate the latest technologies. These machines are designed to maximize efficiency and minimize waste, ensuring that the recycling process is as environmentally friendly as possible.

One of RUMTOO’s innovative solutions is the integration of smart sensors into their pelletizer machines. These sensors monitor various parameters such as temperature, pressure, and flow rate, allowing for real-time adjustments to optimize the recycling process. This not only improves the quality of the pellets but also reduces energy consumption and enhances overall operational efficiency.

Furthermore, RUMTOO’s pelletizer machines are equipped with advanced automation features, such as programmable logic controllers (PLCs) and human-machine interfaces (HMIs). These features enable operators to easily control and monitor the machines, ensuring smooth operation and minimizing downtime.

With continuous advancements in plastic recycling technologies and the commitment of industry leaders like RUMTOO, the future of plastic recycling looks promising. By embracing these innovative solutions, we can make significant strides towards a more sustainable and eco-friendly future.

Enhance Plastic Recycling Processes with RUMTOO

RUMTOO is a company that is dedicated to revolutionizing plastic recycling processes. With their state-of-the-art machines, they are able to provide efficient and sustainable solutions for plastic recycling.

The Company Revolutionizing Plastic Recycling

RUMTOO stands out in the industry for its commitment to innovation. They continuously strive to develop and improve their machines to meet the evolving needs of the recycling industry. Their machines are known for their reliability, efficiency, and exceptional performance.

Cutting-Edge Machines for Efficient Recycling

RUMTOO offers a range of cutting-edge plastic pelletizer machines that are designed to enhance recycling processes. These machines are equipped with advanced features such as high-speed rotors, temperature control systems, and precision cutting technology.

One notable machine is the RUMTOO-2000, which is capable of processing large volumes of plastic flakes and transforming them into high-quality pellets. Its innovative design ensures minimal energy consumption and reduced waste generation.

Another machine offered by RUMTOO is the RUMTOO-500, which is ideal for smaller volume recycling operations. Despite its compact size, it delivers excellent performance and efficiency, making it a valuable asset for businesses of all sizes.

Sustainable Solutions for Plastic Recycling

In addition to their advanced machinery, RUMTOO also prioritizes sustainability in their solutions. They recognize the importance of minimizing the environmental impact of plastic recycling and work towards creating efficient and eco-friendly processes.

One way they achieve this is through the use of energy-efficient components and systems. Their machines are designed to consume less energy, reducing the carbon footprint of the recycling process. Additionally, RUMTOO machines incorporate state-of-the-art filtration systems to ensure that any emissions and waste generated during the process are properly managed and minimized.

But RUMTOO’s commitment to sustainability doesn’t stop there. They also actively collaborate with research institutions and industry experts to explore new ways to improve plastic recycling. By staying at the forefront of technological advancements and industry trends, AMSTAR is able to continuously innovate and offer cutting-edge solutions.

Furthermore, RUMTOO is dedicated to educating and raising awareness about the importance of plastic recycling. They conduct workshops and training programs to equip individuals and businesses with the knowledge and skills needed to implement effective recycling practices.

In conclusion, plastic pelletizer machines play a vital role in PET flakes recycling. Advanced technologies and innovative solutions offered by companies like RUMTOO are driving the industry forward, making the recycling process more efficient and sustainable. With their cutting-edge design and commitment to sustainability, these machines are paving the way for a greener future. By investing in top plastic pelletizer machines, businesses can contribute to the circular economy and help create a world where plastic waste is a thing of the past.