The plastic recycling industry is witnessing a transformative era with the advent of advanced technologies that promise to revolutionize waste management and recycling processes. As the global community becomes increasingly aware of the environmental impacts of plastic waste, the demand for innovative and efficient plastic recycling machines has surged. This article delves into the latest developments in plastic recycling machine technology, focusing on key innovations and how they influence the plastic recycling machine price.

Pyrolysis: A Leap Towards Chemical Recycling

One of the most significant advancements in plastic recycling technology is pyrolysis. Pyrolysis transforms hydrocarbon plastic waste into pyrolytic oil, petrochemicals, and carbon ash residue in the absence of oxygen. This technology not only enables the recycling of massive amounts of waste but also offers a sustainable operation model by reducing energy consumption and emissions. Startups like Pyrolyze and Waste Chakra are at the forefront, offering portable and decentralized solutions that cater to the needs of small and medium recycling businesses, potentially affecting the overall plastic recycling machine price by providing more accessible and cost-effective options.

Innovative Depolymerization and Enzymatic Recycling

Depolymerization stands out as a method to break down plastic waste into monomers, which can be used as raw materials in plastic manufacturing, thereby promoting a circular economy. Companies like Scindo and DePoly are pioneering enzymatic and chemical depolymerization processes. These innovations not only enhance the quality of recyclates but also offer high commercial value by substituting fossil-fuel-based raw materials, which could influence the plastic recycling machine price by adding value to the output.

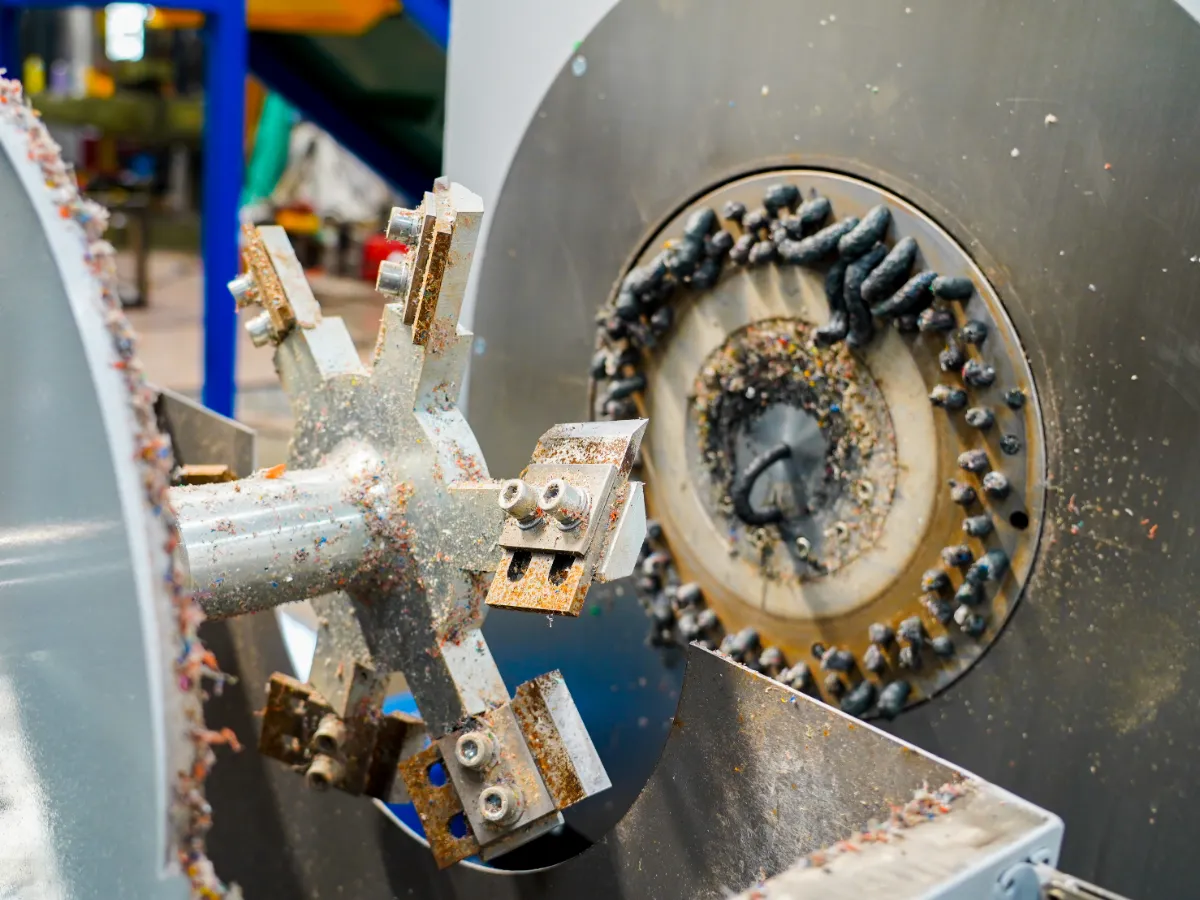

Advanced Mechanical Recycling and IoT Integration

Advancements in mechanical recycling, supported by AI and IoT technologies, are improving the efficiency of waste sorting and recycling processes. The integration of the Internet of Waste, leveraging fill-level sensors, smart bins, and material quality assessing sensors, optimizes waste collection and operational efficiency. Innovations in sorting technologies, such as the use of NIR spectroscopy and fluorescent markers for precision sorting, are critical for increasing the purity and quality of recycled materials.

Digital Watermarking and Sorting Technologies

Digital watermarking, as part of the HolyGrail project, emerges as a promising technology to improve post-consumer recycling accuracy. This technology allows for more precise sorting than current methods, potentially enabling better identification of multi-material structures and enhancing the efficiency of recycling processes. Companies like Digimarc are leading the way in this field, offering solutions that could significantly impact the effectiveness and cost of recycling operations.

Impact on Plastic Recycling Machine Price

The incorporation of these advanced technologies into plastic recycling machines is likely to influence their price. On one hand, innovations like pyrolysis plants and enzymatic recycling solutions may initially increase the cost due to the sophisticated technology and research involved. On the other hand, improvements in efficiency, the potential for higher-quality recyclates, and the development of portable and decentralized models could reduce operational costs and make recycling more economically viable in the long run.

Conclusion

The latest developments in plastic recycling machine technology are setting the stage for a more sustainable and efficient future in waste management. While these innovations may affect the plastic recycling machine price, the long-term benefits—ranging from environmental sustainability to economic viability—underscore the importance of investing in advanced recycling technologies. As the industry continues to evolve, it is crucial for stakeholders to stay informed and adapt to these changes, ensuring that the benefits of recycling technology advancements are maximized for a greener future.

For businesses and investors, understanding these trends is crucial for making informed decisions regarding the adoption of new technologies and the implications for plastic recycling machine prices. As the sector grows, the focus on sustainability, efficiency, and innovation will continue to drive advancements, making plastic recycling an increasingly vital component of global waste management strategies.

Frequently Asked Questions

What is plastic recycling machine technology?

Plastic recycling machine technology encompasses the methods and devices used to recycle plastic waste into usable materials or products. Innovations in this field aim to improve efficiency, reduce energy consumption, and enhance the quality of recycled plastics.

How does pyrolysis work in plastic recycling?

Pyrolysis involves the thermal degradation of plastic waste in the absence of oxygen to produce pyrolytic oil, petrochemicals, and carbon ash residue. This technology allows for the recycling of massive amounts of plastic waste into fuel and other valuable products.

What are the benefits of enzymatic recycling?

Enzymatic recycling uses biological catalysts to break down plastics into high-quality monomers. This method ensures the purity of recycled materials, enabling them to replace fossil-fuel-based raw materials in manufacturing, thus promoting a circular economy.

Can digital watermarking improve recycling processes?

Yes, digital watermarking involves embedding invisible codes on packaging, which can be detected by sorting machines to accurately sort waste materials. This technology enhances the precision and efficiency of recycling processes.

How do advancements in recycling technology affect plastic recycling machine prices?

While initial costs for advanced recycling machines may be higher due to sophisticated technology, these innovations can lead to reduced operational costs, higher quality recyclates, and more economically viable recycling operations in the long run.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.

[contact-form-7 id=”c9499fe” title=”Contact form 2″]