When it comes to recycling and waste management, understanding the differences between shredders and crushers is crucial for anyone looking to invest in machinery that optimizes processing and production efficiency. While both are essential for breaking down materials, their applications, capacities, and the final material output differ significantly.

Understanding Shredders

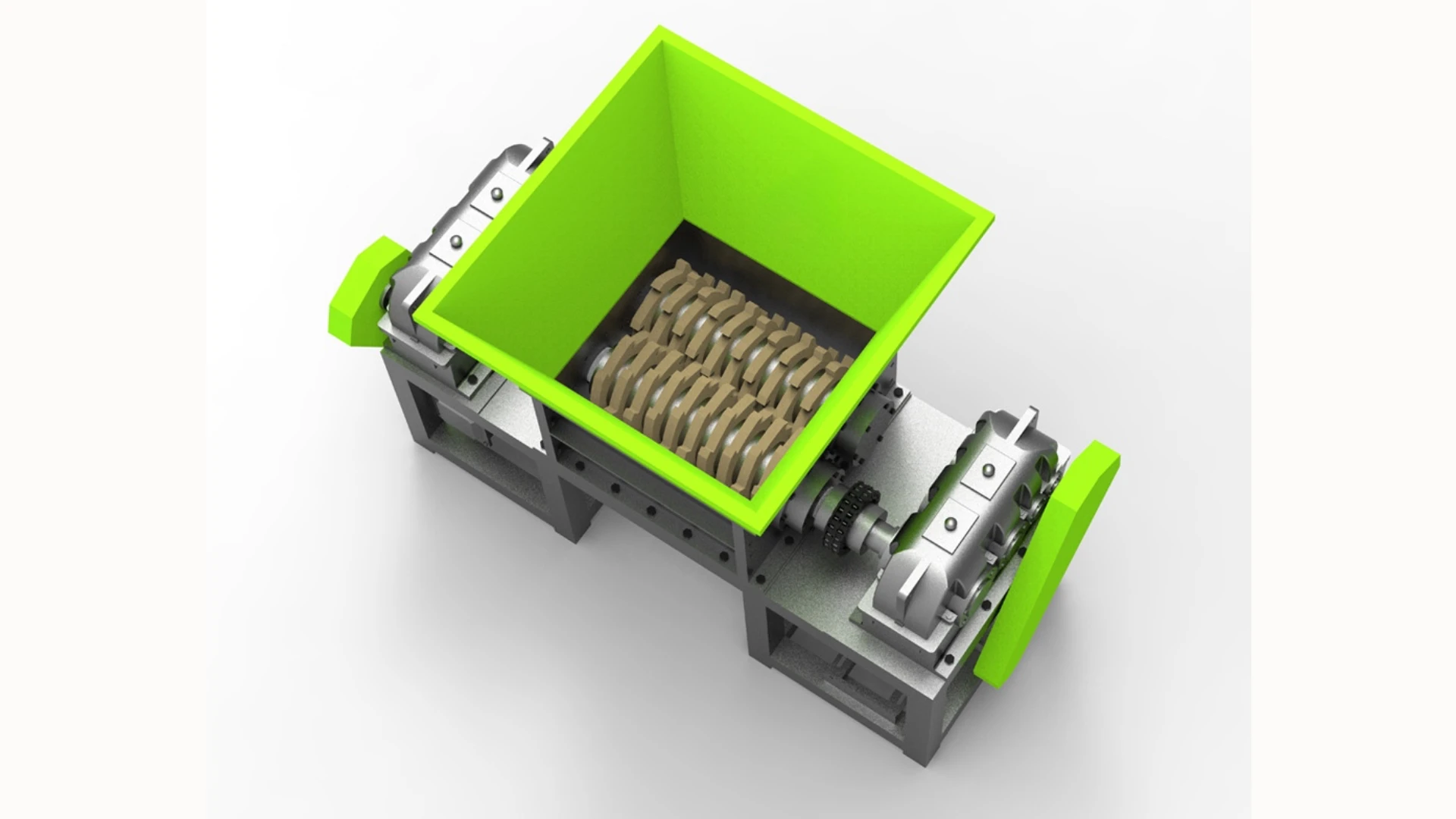

Shredders are eco-friendly devices designed to tear large, unwieldy materials into smaller, more manageable pieces. These machines are perfect for handling a wide variety of recyclable materials including old plastics, waste boards, and used tires. Shredders are distinguished by their low-speed, high-torque mechanics which allow them to produce irregularly shaped pieces ranging from 20mm to 200mm or larger. This capability makes them ideal for the initial breakdown of solid waste.

Types of Shredders

• Four-shaft shredders

Shredders operate by using cutting tools to shear, tear, and shred materials. They are typically employed to process raw materials or scraps that haven’t been pre-treated, such as plastic trimmings or rubber edges. Shredders are particularly common in the plastic recycling industry where they preprocess large PE plastic pipes, bundled plastic film, and large stacks of plastic sheets.

Understanding Crushers

Crushers, on the other hand, are used to further reduce the size of the pre-shredded material into smaller particles, typically below 20mm, making them suitable for subsequent processing steps like cleaning and pelletizing. The principle behind crushers involves high-speed rotating blades that crush materials through high inertial impact and sharp cutting.

Typical Uses of Crushers

• Mining: to break down stones.

• Recycling industry: to crush shredded plastics into granules ready for further processing.

Key Differences Between Shredders and Crushers

1. Material Size:

• Shredders: Produce larger, irregular pieces (20mm–200mm).

• Crushers: Break these pieces down into smaller sizes (<20mm).

2. Operating Principle:

• Shredders: Utilize low speed and high torque.

• Crushers: Employ high-speed cutting and high inertial impacts.

3. Material Type:

• Shredders: Ideal for durable, large, and tough materials.

• Crushers: Better suited for smaller, less robust materials.

4. Operational Efficiency:

• Shredders: Safer, require less manual intervention, and are quieter.

• Crushers: Typically noisier and require more manual labor.

How to Choose the Right Equipment

Choosing the right machine starts with two critical questions:

1. What materials do you need to process, and in what form are they currently?

2. What size do you need the processed materials to be?

For instance, materials could range from plastics and paper to rubber, PVC, old tires, household garbage, large furniture, and even medical waste. Depending on the intended end use of the processed materials—whether for manufacturing, recycling, or disposal—the size to which the materials need to be reduced can vary significantly.

Common Applications in the Recycling Industry

• Reducing the volume of waste, thereby decreasing transportation costs.

• Shredding tires for use as fuel or filler material.

• Crushing confidential documents to prevent them from being read.

• Preprocessing plastics for recycling.

Conclusion

Understanding the distinct functions and advantages of shredders and crushers allows businesses and individuals in the recycling industry to make informed decisions about which equipment is best suited for their needs. By considering the type and size of materials to be processed, as well as the desired output size, you can effectively choose the right machinery to enhance your operational efficiency and environmental impact.