Introduction

In the context of global environmental pressures and resource recycling imperatives, plastic recycling has emerged as a critical industry. For entrepreneurs and existing businesses looking to enter this field, understanding the costs associated with plastic recycling machines is paramount. These machines are the cornerstone of initiating and maintaining plastic recycling operations, and their costs directly impact the total investment required and the potential return on investment.

The market demand for plastic recycling machines continues to grow, partly due to increasingly stringent global regulations on plastic waste management and heightened public awareness of environmental issues. Effective plastic recycling not only reduces environmental pollution but also presents new business opportunities through the sale of recycled plastic products. Consequently, investors and recycling enterprises are seeking cost-effective plastic recycling solutions.

This article aims to provide a comprehensive analysis of plastic recycling machine prices, enabling readers to understand the various types of machines available and their price structures, thereby facilitating more informed investment decisions. Through a detailed discussion of the types of plastic recycling machines, pricing factors, and cost-benefit considerations, this article will illuminate the economic and environmental potential of these machines.

Types of Plastic Recycling Machines

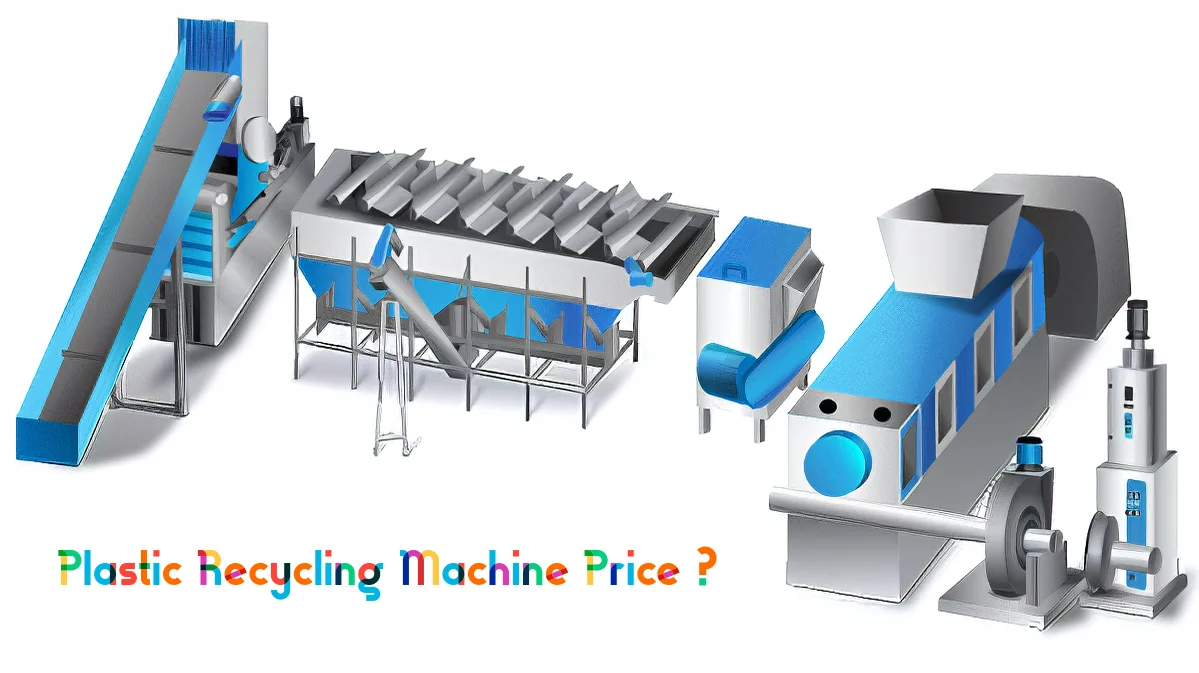

The plastic recycling process encompasses several critical steps, each of which may utilize different types of machinery. Understanding the functions and technical characteristics of these machines is crucial for selecting appropriate equipment and optimizing the recycling process.

The following are common types of plastic recycling machines, their uses, and technical characteristics:

1. Shredder

- Purpose: To break down waste plastic products into small pieces for easier subsequent processing.

- Technical characteristics:

- Diverse types:

- Single-shaft shredder: Simple structure, suitable for soft plastics.

- Double-shaft shredder: High efficiency, suitable for hard plastics.

- Adjustable size: Can adjust shredding size as needed.

- Safety protection: Equipped with safety devices to prevent operator injury.

- Diverse types:

2. Washing Line

- Purpose: To clean shredded plastic particles, removing dirt, grease, labels, and other impurities.

- Technical characteristics:

- Multi-stage cleaning: Usually includes pre-washing, rinsing, dewatering, and other steps.

- Separation technology: Utilizes principles of density and buoyancy to separate impurities of different materials.

- Water recycling system: Conserves water resources and reduces environmental pollution.

3. Pelletizer

- Purpose: To melt cleaned plastic particles and shape them into uniform plastic pellets.

- Technical characteristics:

- Heating methods:

- Friction heating: Utilizes friction to generate heat and melt plastic.

- Electric heating: Uses electric heating elements to heat plastic.

- Die design: Different plastic types require different dies.

- Controllable pellet size: Can adjust pellet size as needed.

- Heating methods:

- Purpose: To classify plastics based on type, color, and other characteristics.

- Technical characteristics:

- Optical recognition: Uses spectral analysis technology to identify different types of plastics.

- Manual sorting: In some cases, manual assistance is required for sorting.

- High degree of automation: Improves sorting efficiency and accuracy.

5. Other Equipment:

- Dryer: Used to remove moisture from plastics.

- Mixer: Used to blend different types of plastics uniformly.

- Packaging Machine: Used to package the final product.

Factors to consider when choosing suitable plastic recycling machines:

- Plastic type: Different plastic types require different processing methods.

- Recycling volume: Larger processing volumes require equipment with higher power and efficiency.

- Budget: Different types of equipment vary greatly in price.

- Environmental requirements: Choose energy-efficient and environmentally friendly equipment.

Pricing Factors

The price of plastic recycling machines is influenced by various factors, including the type of final product, expected output, equipment operation time, number of production lines, and the degree of plastic shredding fineness. Understanding how these factors affect equipment costs is crucial for making investment decisions.

- Type and Volume of Final Product: The final product may be mixed shredded plastic, separately shredded polymers, or plastic pellets. Mature recycling plants may produce a portion as pellets and the rest as mixed shredded polymers. The expected output for each product directly affects the scale and configuration of required equipment.

- Equipment Operation Time: If the equipment needs to run continuously (24/7/365), this will place higher demands on equipment durability and maintenance cycles, potentially increasing initial investment and long-term maintenance costs.

- Number of Production Lines: In places like the United States, it is more efficient to have separate production lines for each final product, stopping only for maintenance. With a single production line, stopping and thoroughly cleaning between product changes is necessary to avoid contamination and ensure product quality.

- Degree of Plastic Shredding Fineness: Higher shredding fineness typically requires more expensive equipment. If selling shredded plastic, the shredding size must be adjusted according to buyer requirements; for pellet production, shredding size depends on extruder specifications.

- Additional Equipment and Costs: • Shredding and Washing Equipment: A set including shredders, washers, and dryers may cost between $5,000 to $50,000, depending on production volume. • Pellet Production Equipment: Includes extruders suitable for recycled plastic types, water baths, pelletizers, and sorters. In the U.S., such equipment may cost between $100,000 to $500,000. • Electrical and Auxiliary Equipment: High-capacity power systems, air compressors, water chillers, loaders, forklifts, and other auxiliary equipment are part of the cost consideration, potentially ranging from $50,000 to $200,000.

Generally, the cost of setting up a small plastic recycling plant ranges from $50,000 to $500,000.