What is a common issue with recycling plastic bags

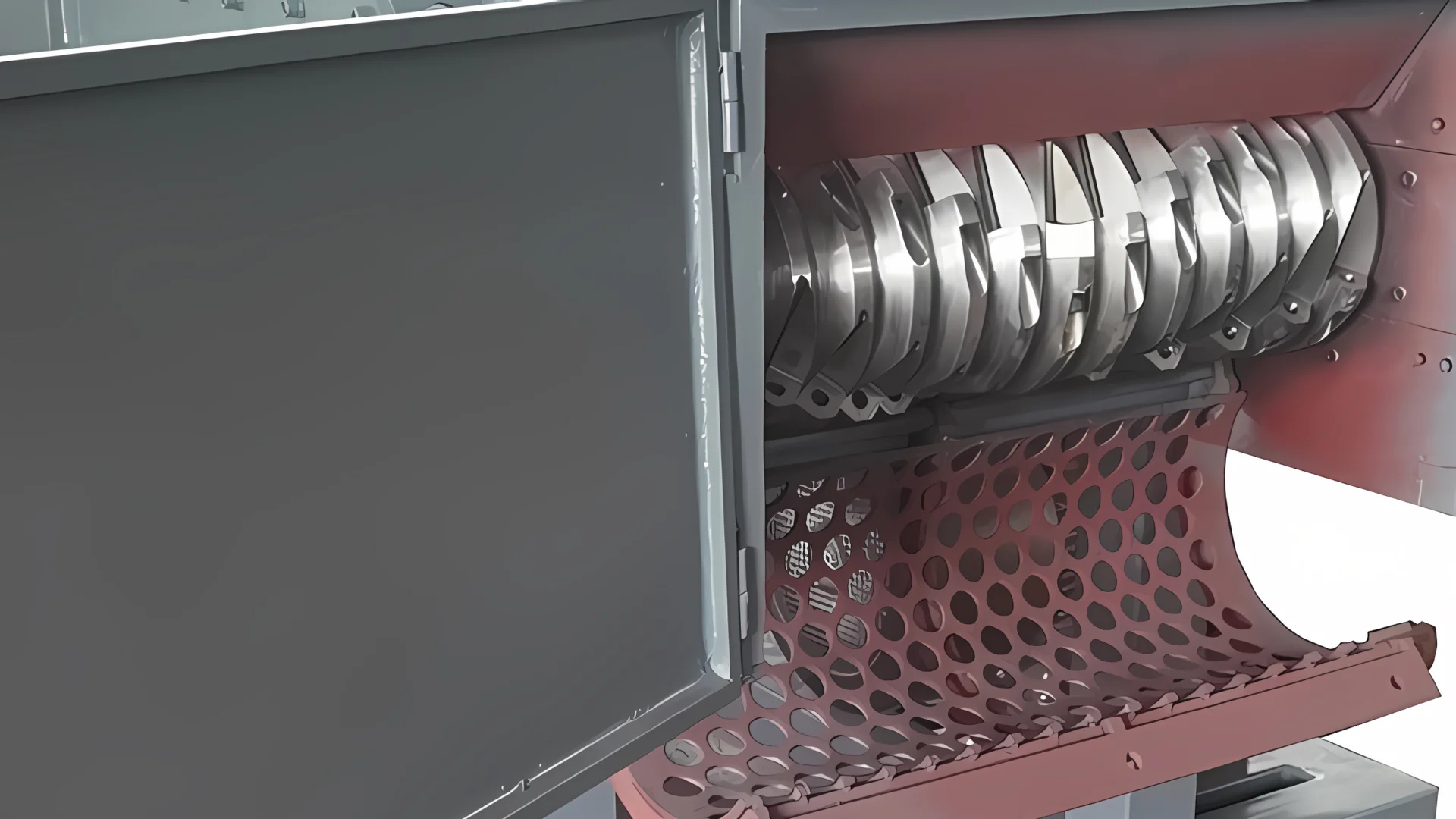

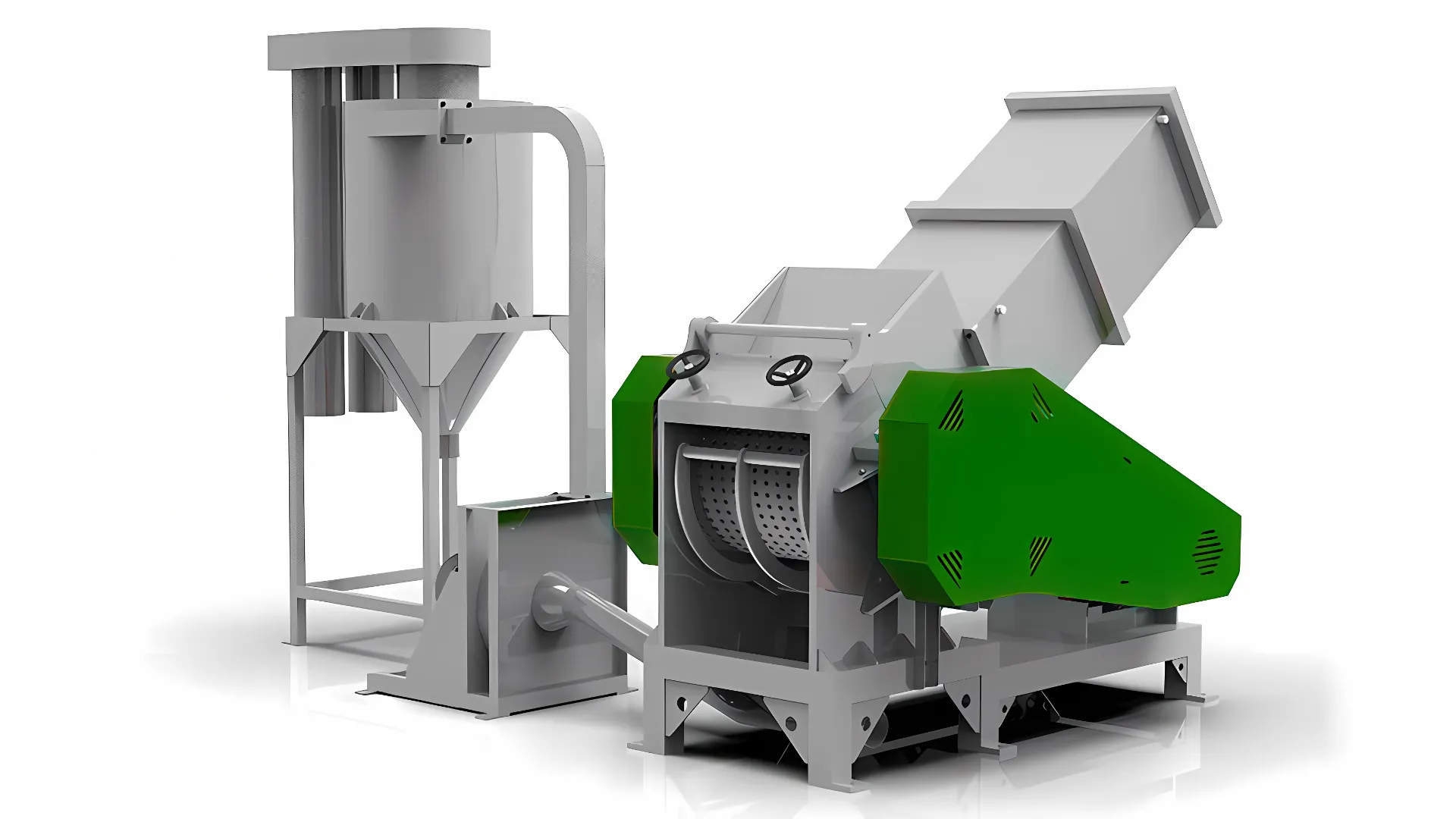

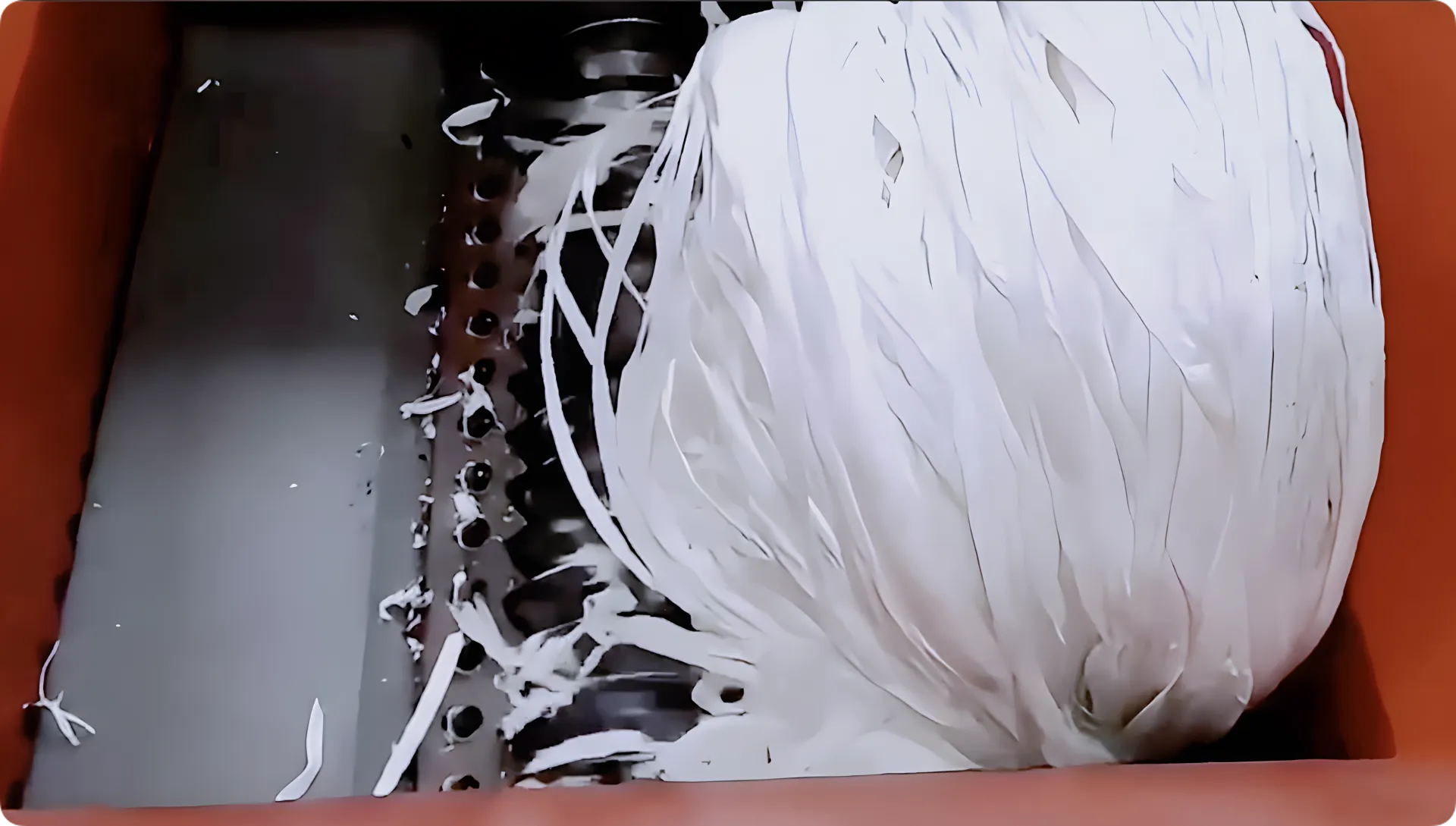

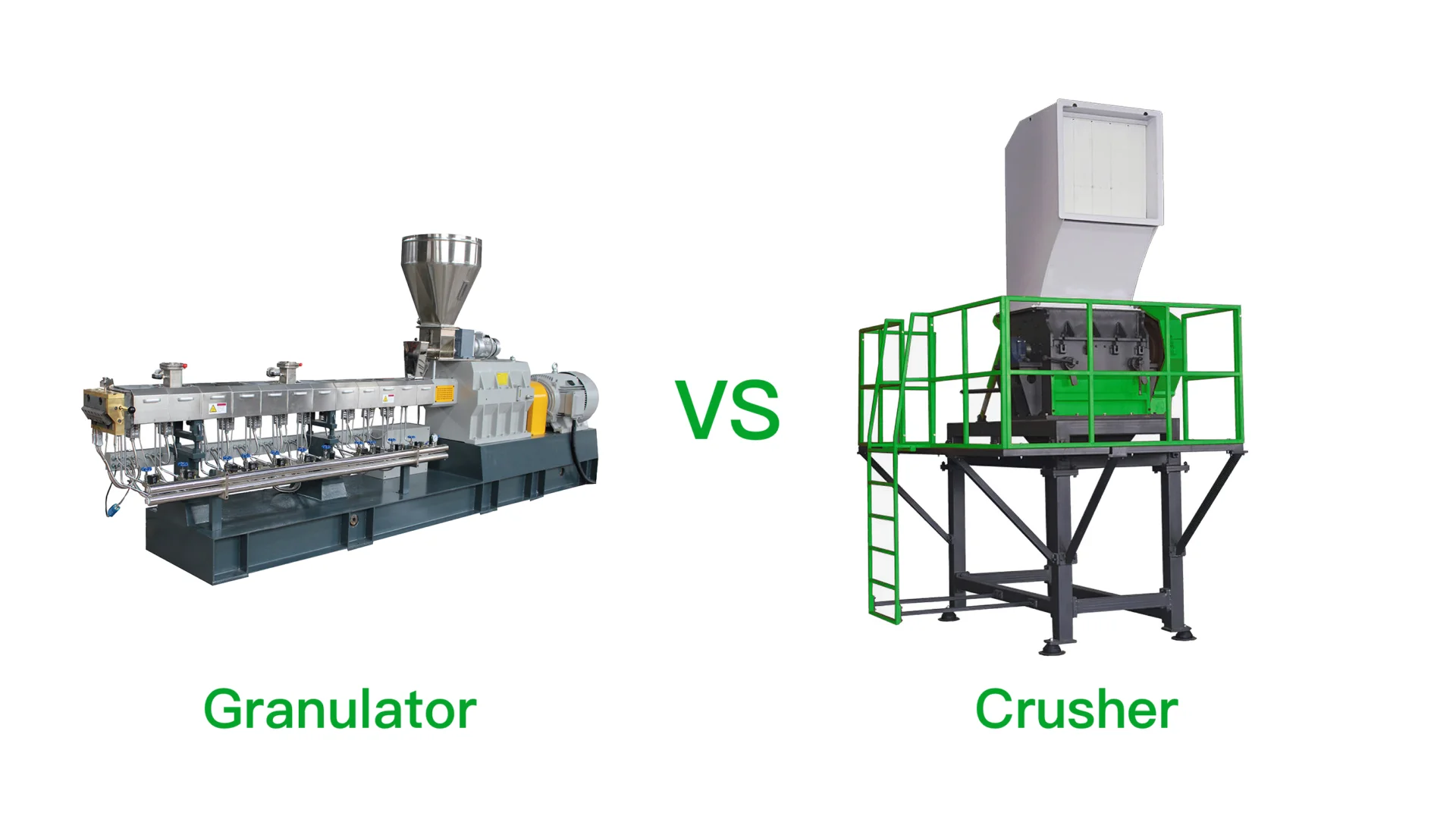

Recycling plastic bags sounds simple, but in reality, it poses a number of issues. From contamination risks to machinery damage, plastic bag recycling has its complexities. Let’s dive into the most common problems and explore ho...