The Complete Guide to Rigid Recycling Machine Applications

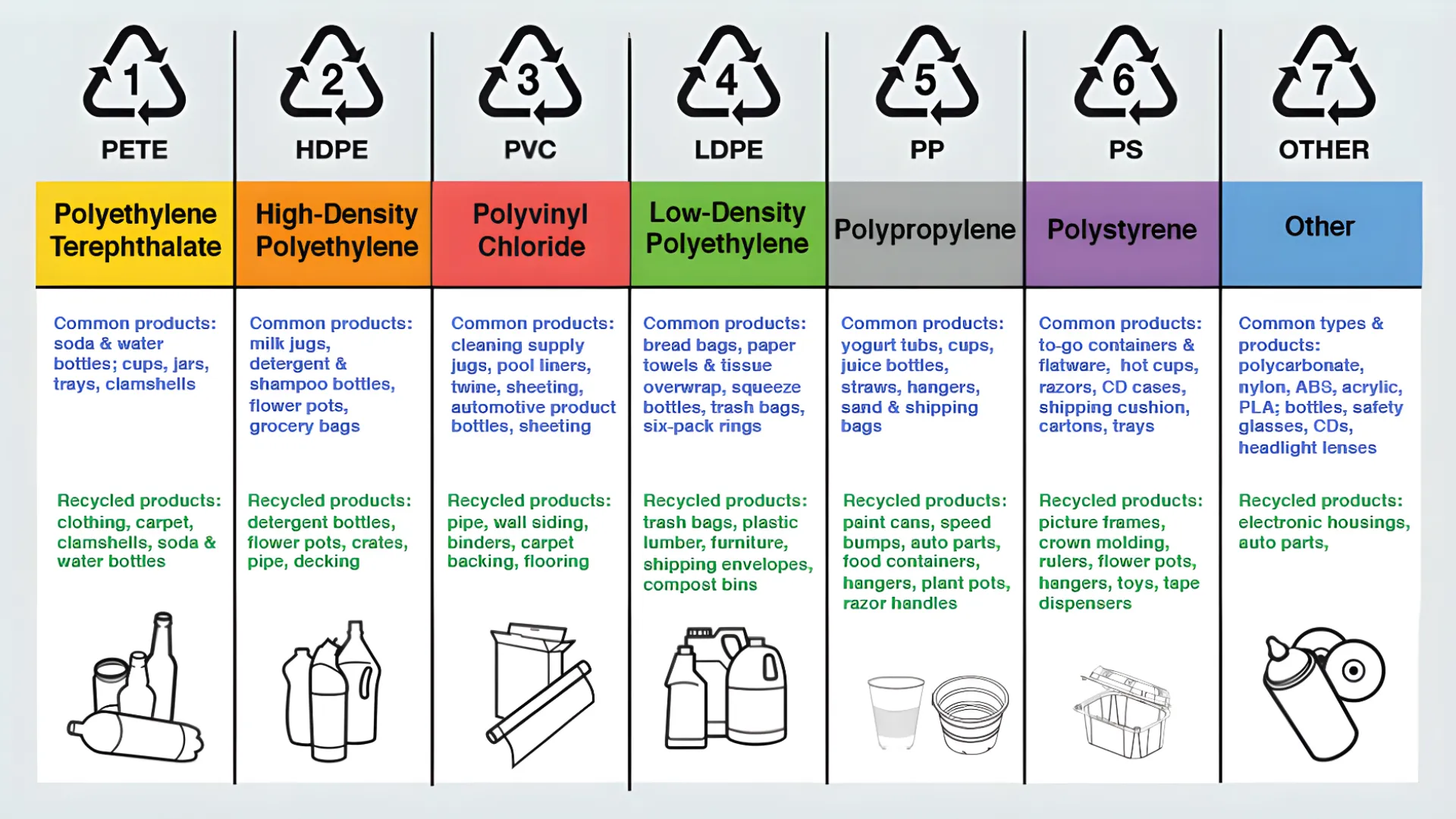

Rigid recycling machines are transforming waste management across major industries, offering sustainable solutions for processing hard materials like plastics, metals, and glass. This comprehensive guide explores how these innovat...