PP PE Film Regrind Washing and Recycling Line

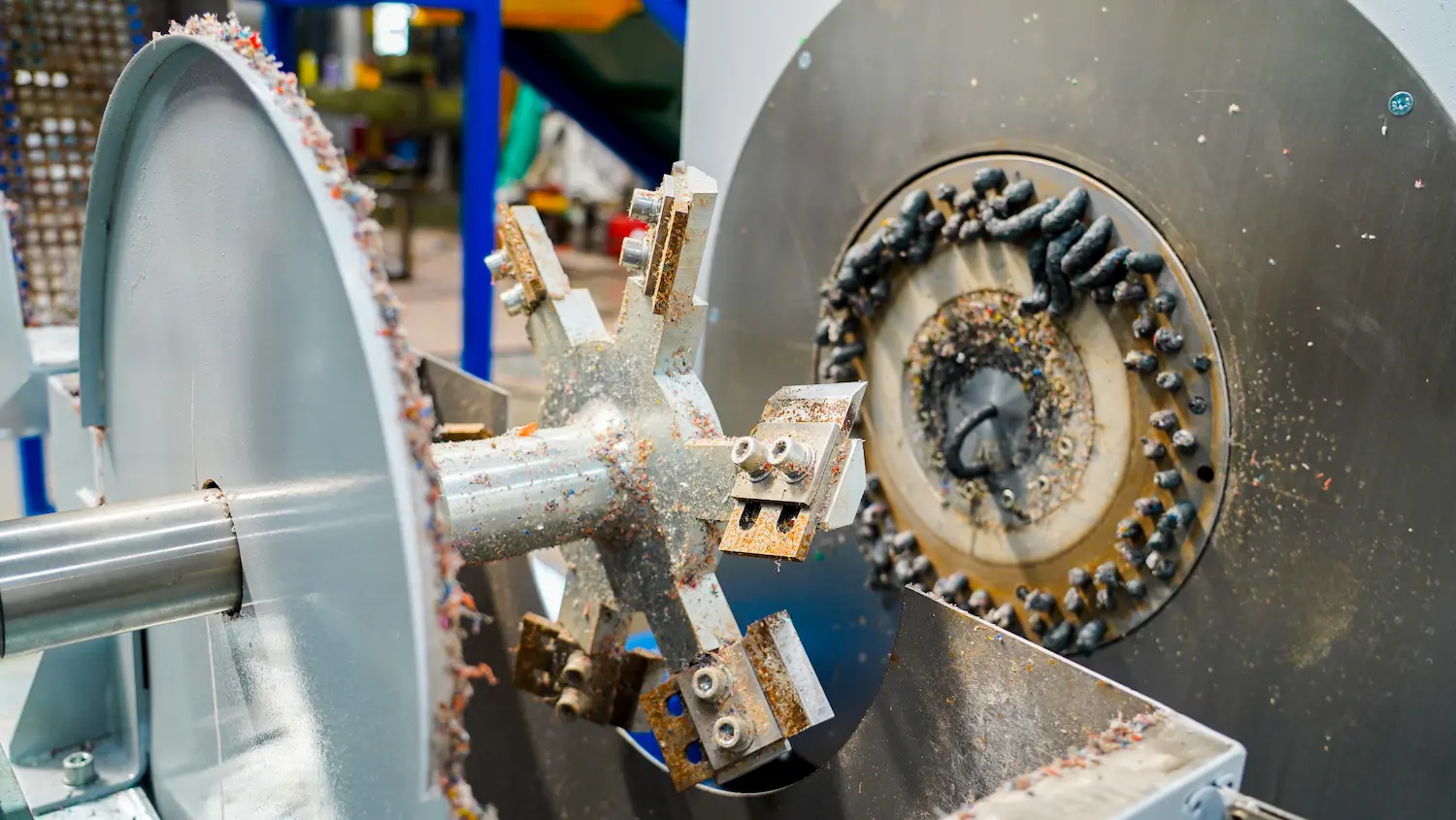

The entire line is designed to clean shredded PP/PE regrind, featuring a friction washer, floatation tank, centrifugal dryer, squeezer, extruders, and pellet cutting system. Below are explanations for some of the key machines:...