Why HDPE Pipes Require Specialized Shredders

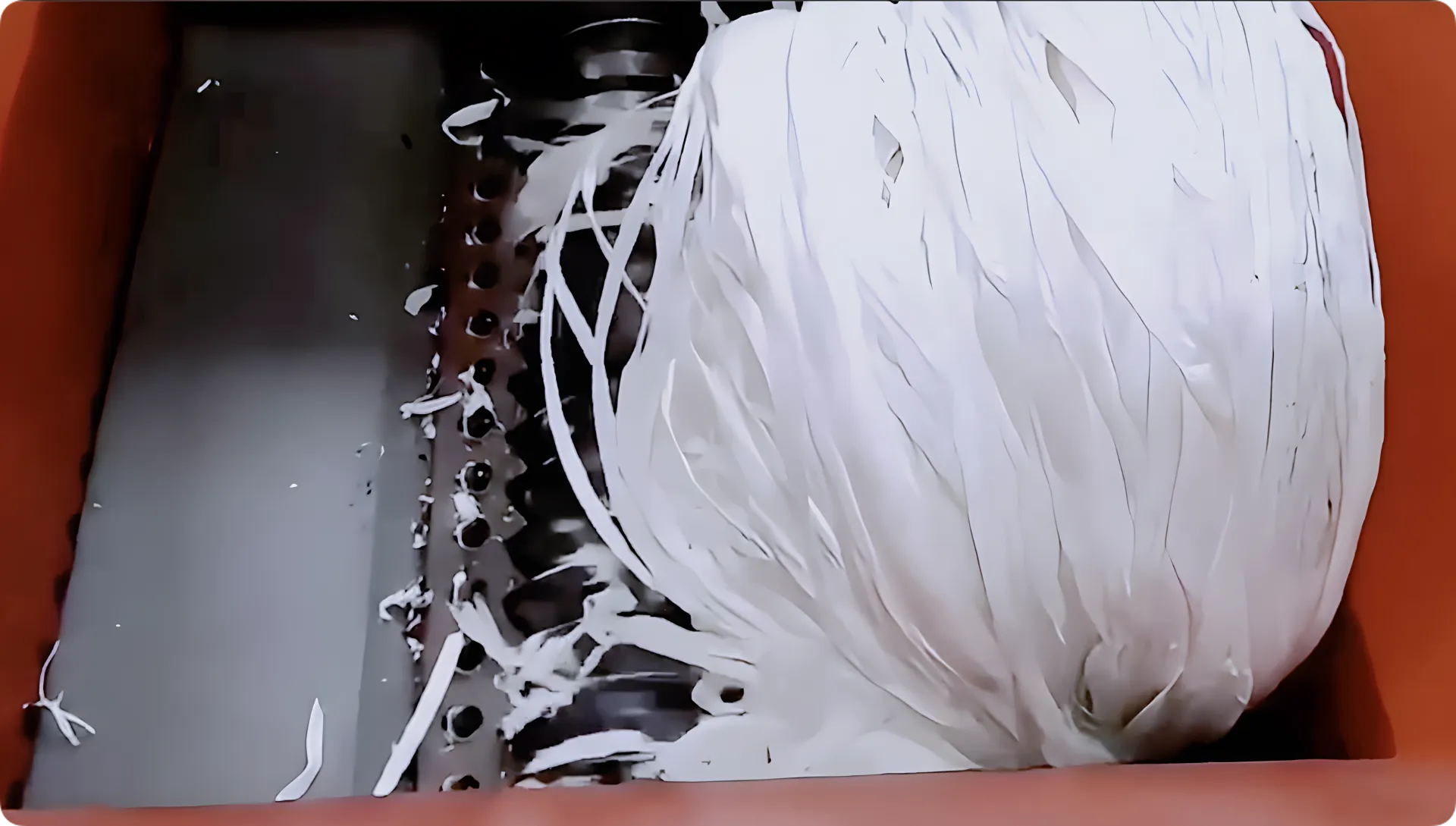

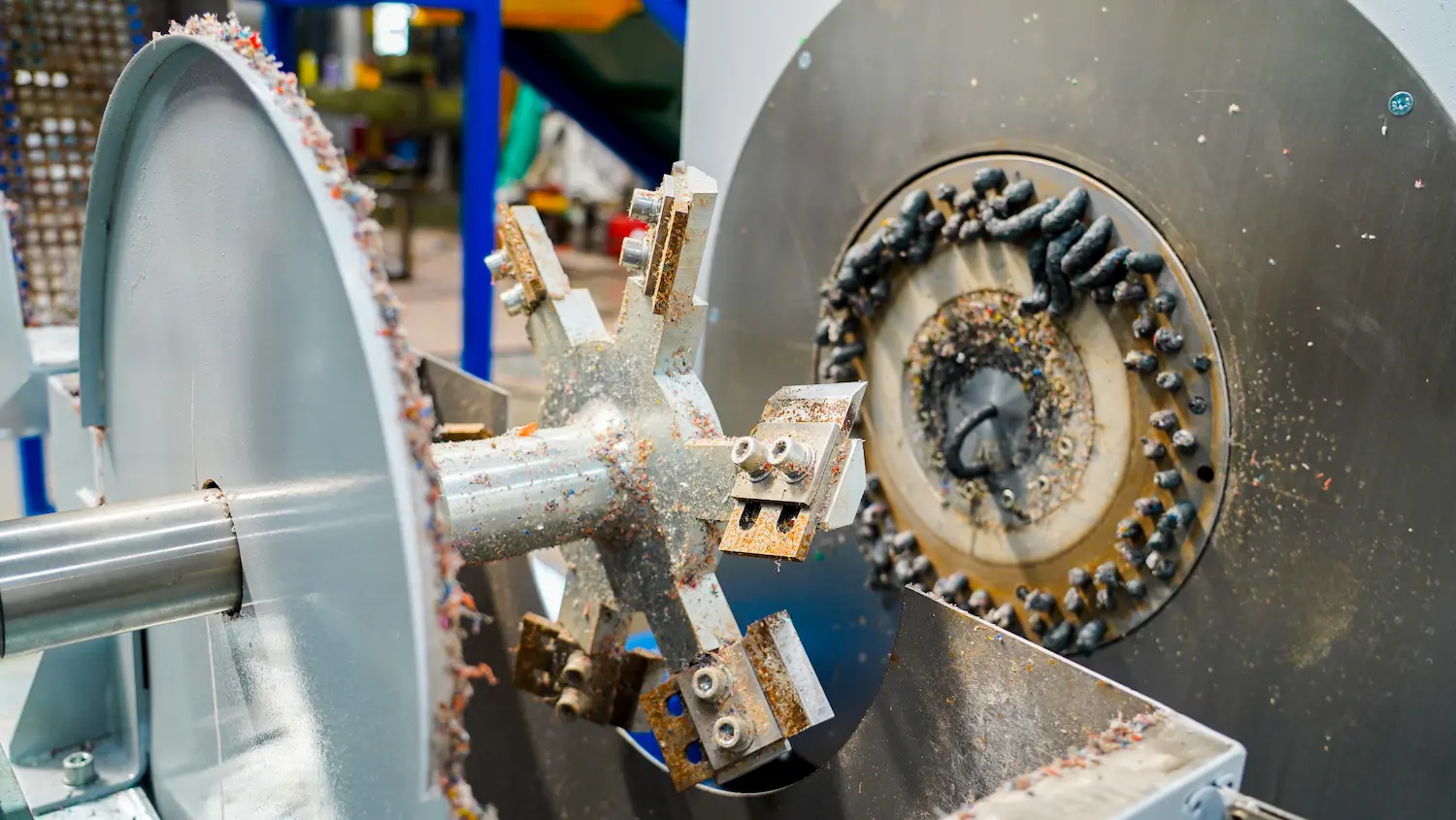

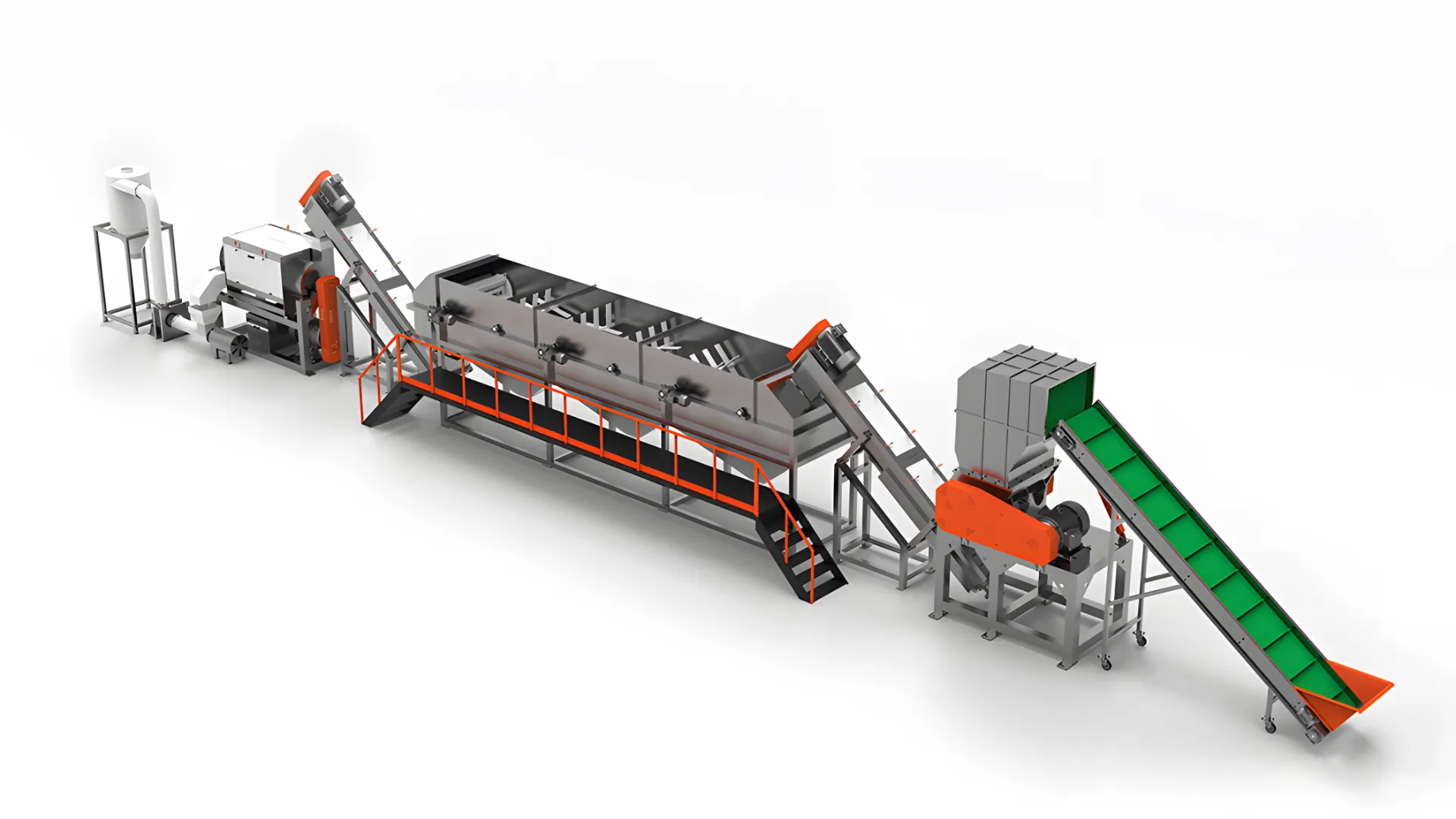

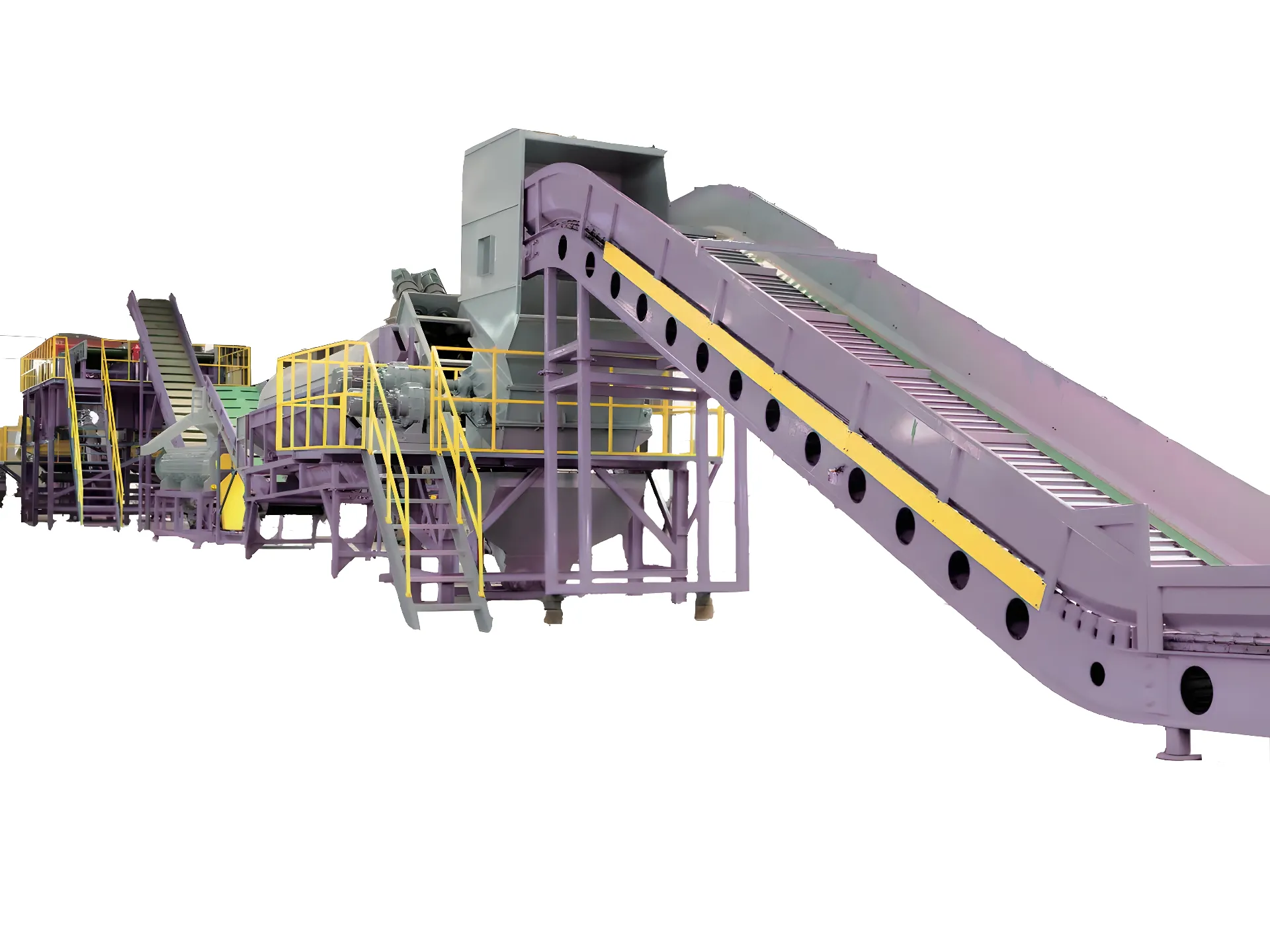

HDPE (High-Density Polyethylene) pipes are widely used across various industries due to their durability, flexibility, and resistance to corrosion. However, their resilience also makes them challenging to recycle, which is why spe...