How PVC Recycling Machines Enhance PVC Profile Recycling

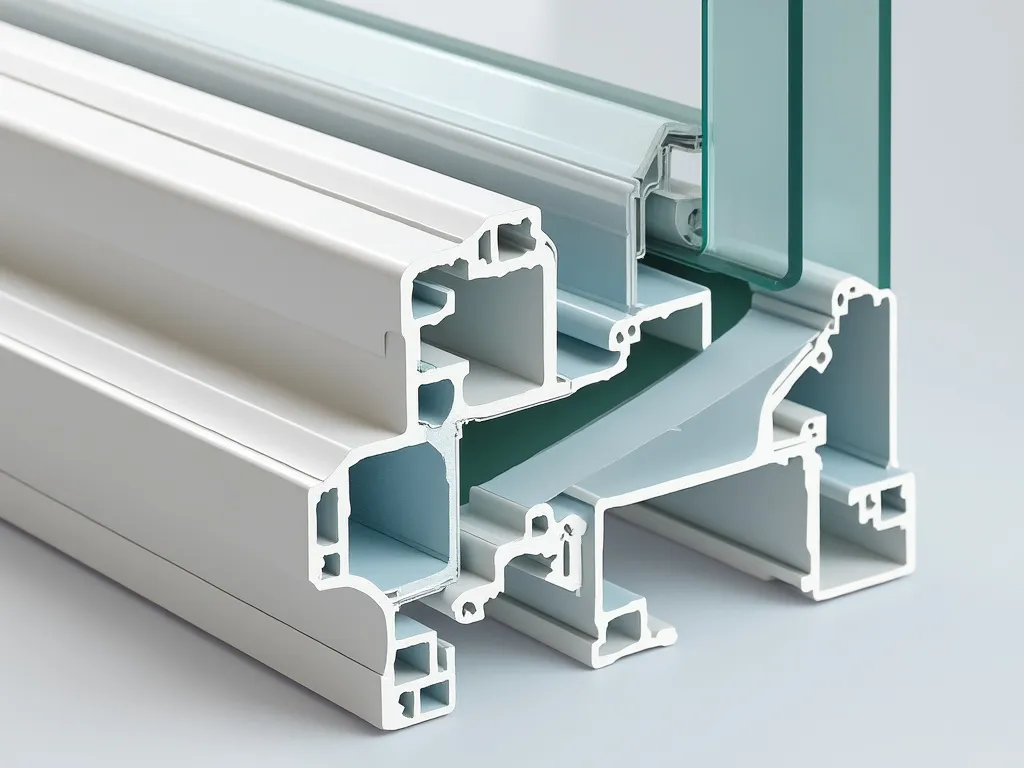

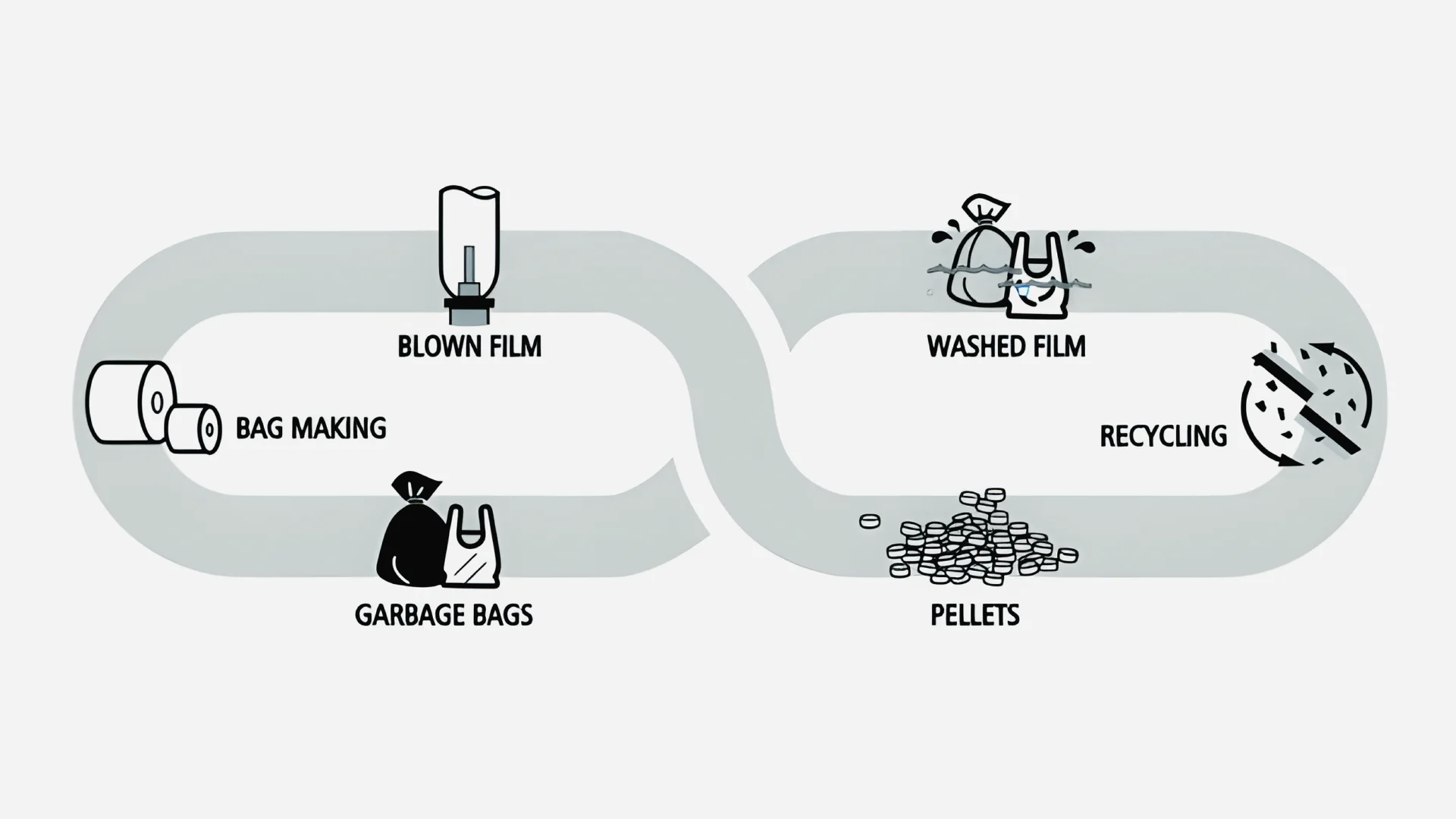

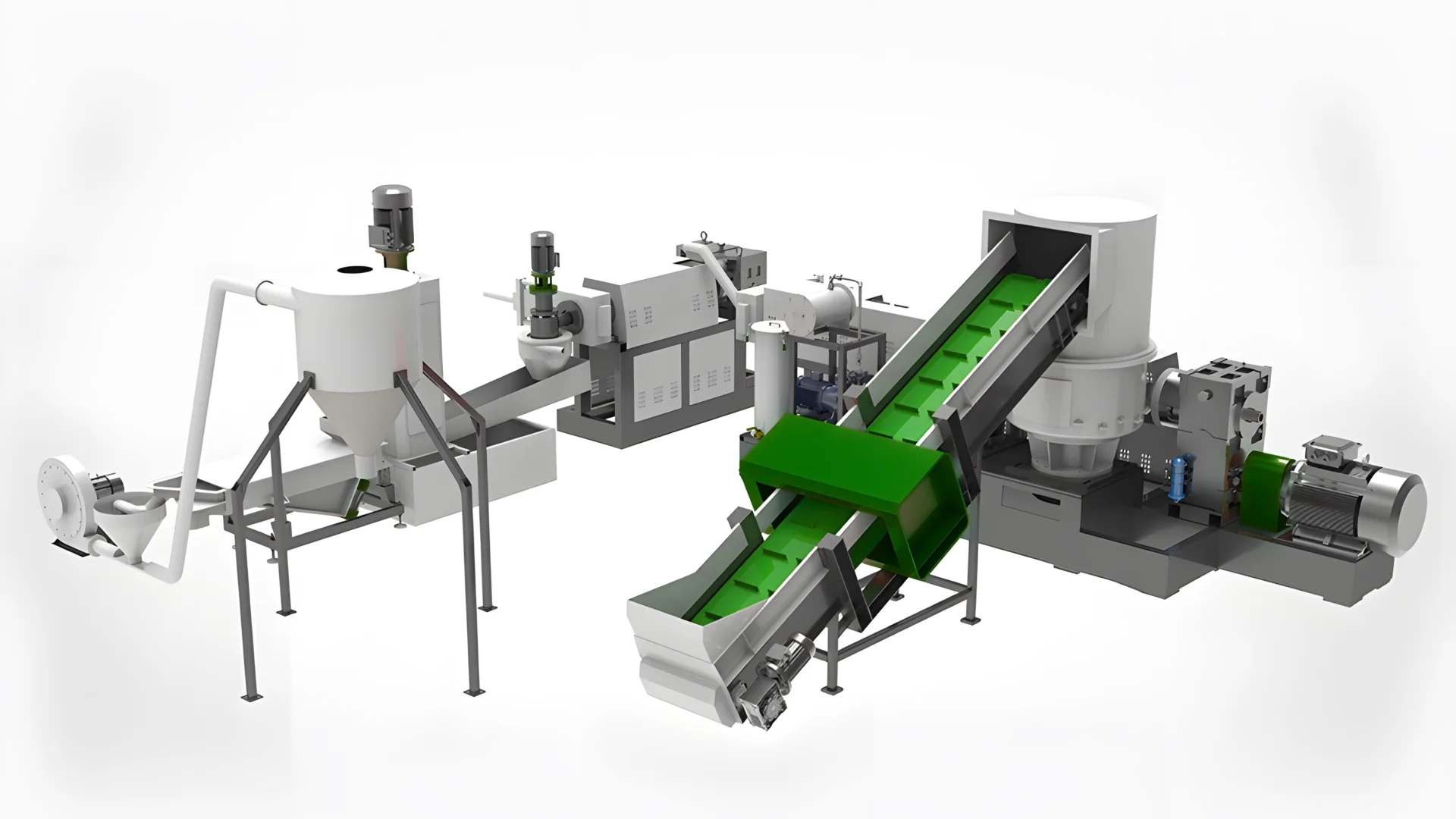

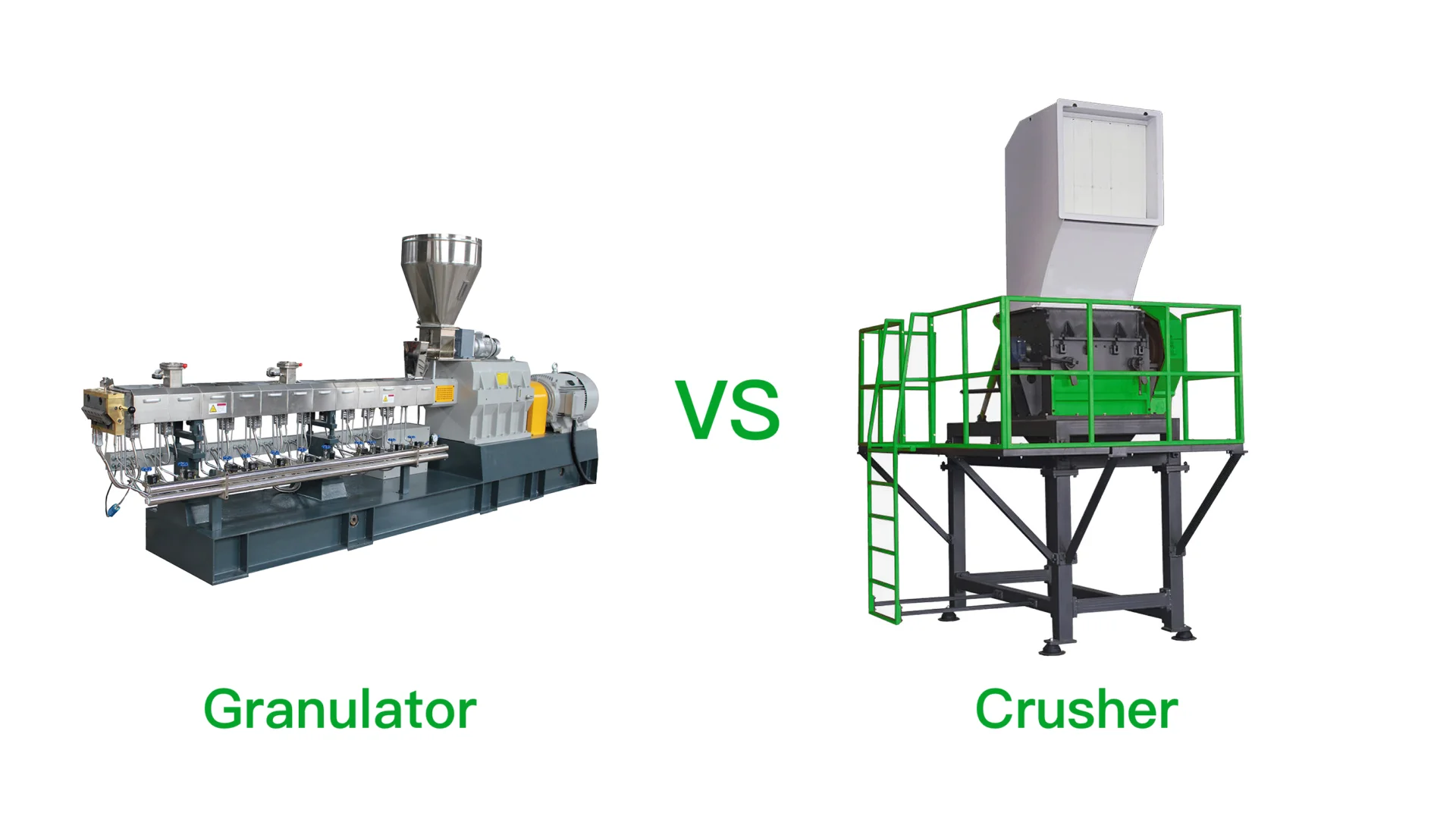

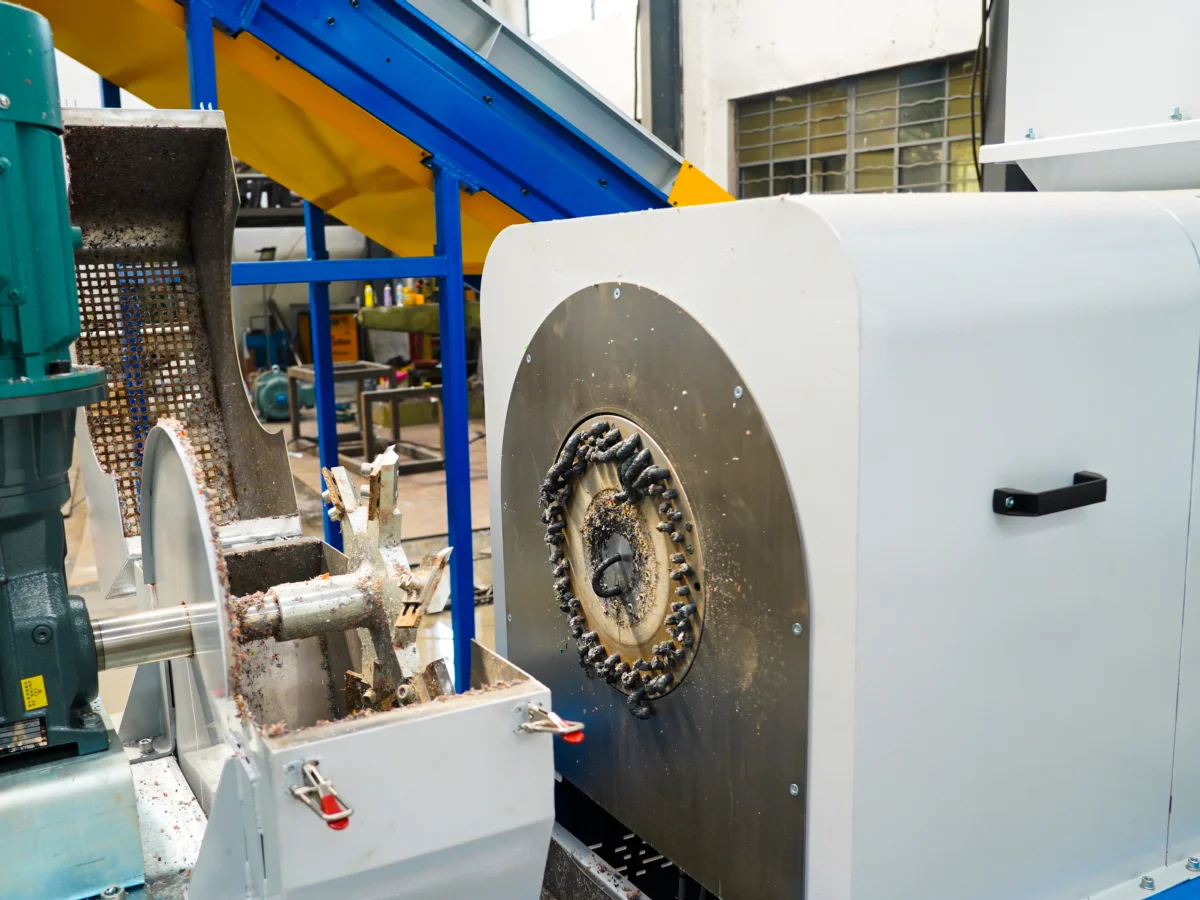

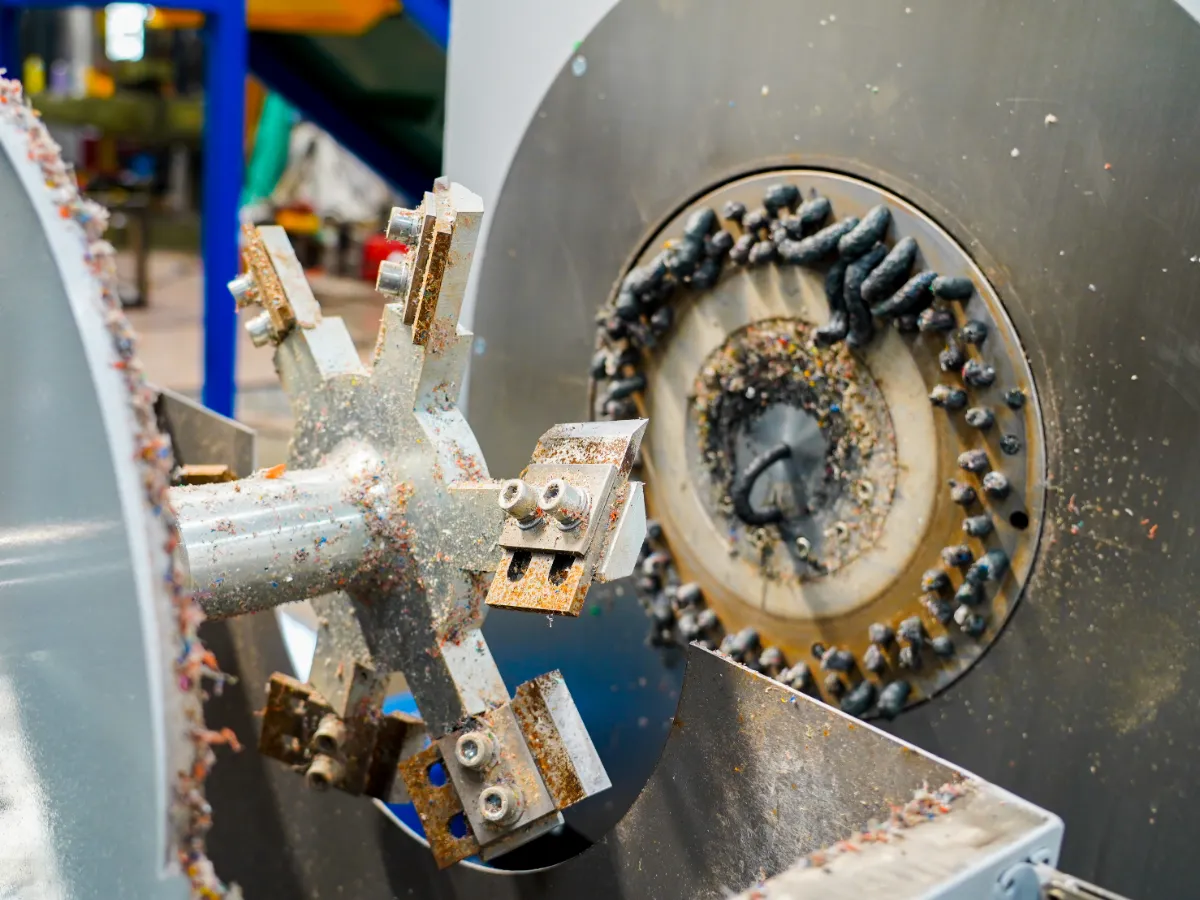

PVC Recycling Machine technology plays a crucial role in the circular economy, particularly in recycling PVC profiles. Companies like Deceuninck are leading the way by recycling PVC window profiles, transforming them into new...

_7.webp)