A sink-float separation tank efficiently segregates materials that float from those that sink. In the context of PET recycling, where PET bottles are granulated whole, a significant portion of contamination comes from plastic bottle caps, which are not composed of PET plastic. Instead, they are made from either polypropylene (PP) or polyethylene (PE).

Working Principle

Rumtoo’s sink-float separation tank utilizes the density of water to achieve separation. Water has a density of 1 g/cm³, meaning any material with a higher density will sink, while material with a lower density will float. In PET bottle recycling, when the stream of material enters the sink/float separation tank filled with water, PET plastic sinks to the bottom, while PP/PE bottle caps float to the surface.

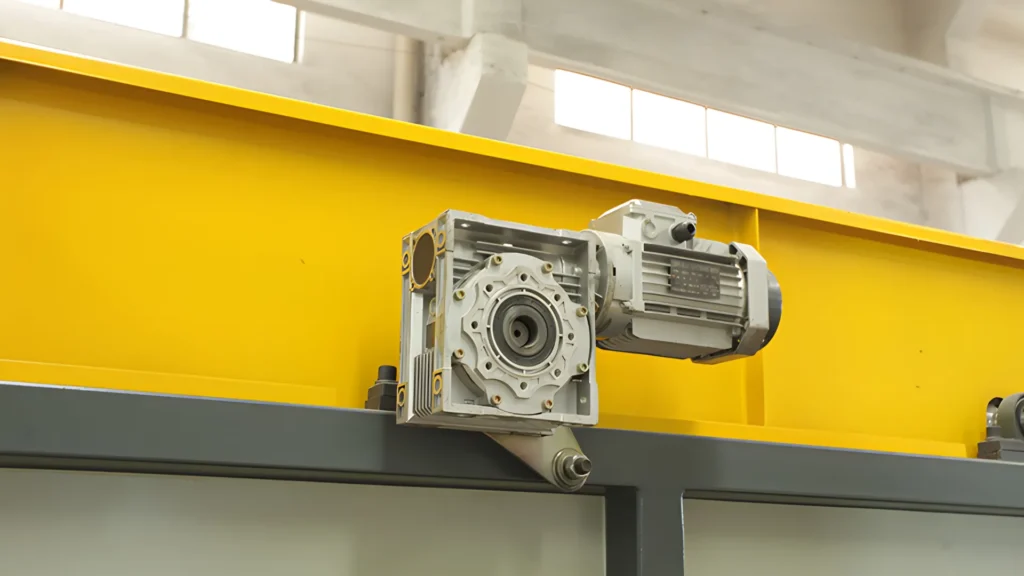

Specially engineered rotating drums propel the floating material (the contamination) forward into a storage silo for collection. Screw conveyors at the bottom of the separation tank gather the PET flakes, moving them onward to the next piece of machinery.

Specifications

For optimal performance, it’s essential for the material to soak in the water for an extended period. This not only enhances the cleaning process but also ensures that all sinking PET flakes have sufficient time to settle at the bottom of the tank. Therefore, we offer a standard 4-meter separation tank with an option to extend it to 6 meters.

To ensure the longevity of Rumtoo’s water separation tank, the tank’s interior, as well as the rotating drums, are constructed from type 304 stainless steel, which is highly resistant to both oxidation (rust) and corrosion.

| Specification | Details |

|---|---|

| Interior Width | 1500mm – 2000mm |

| Total Length | 4 – 6 meters |

| Interior Material | Type 304 Stainless Steel |

| Exterior Frame | Carbon Steel |

| Screw Conveyor Motors | 5.5KW + 3.7KW |

| Rotating Drum Motors | 0.37KW + 2.2KW |

Warranty & Installation

Each recycling machine includes a 1-year limited warranty. We provide installation services, with our engineers visiting your site to assist with the setup process. Arrangements for regular maintenance crews and operational consultants can also be made.

Inquire Now

To get the latest prices and lead times, send us a message using the form below.