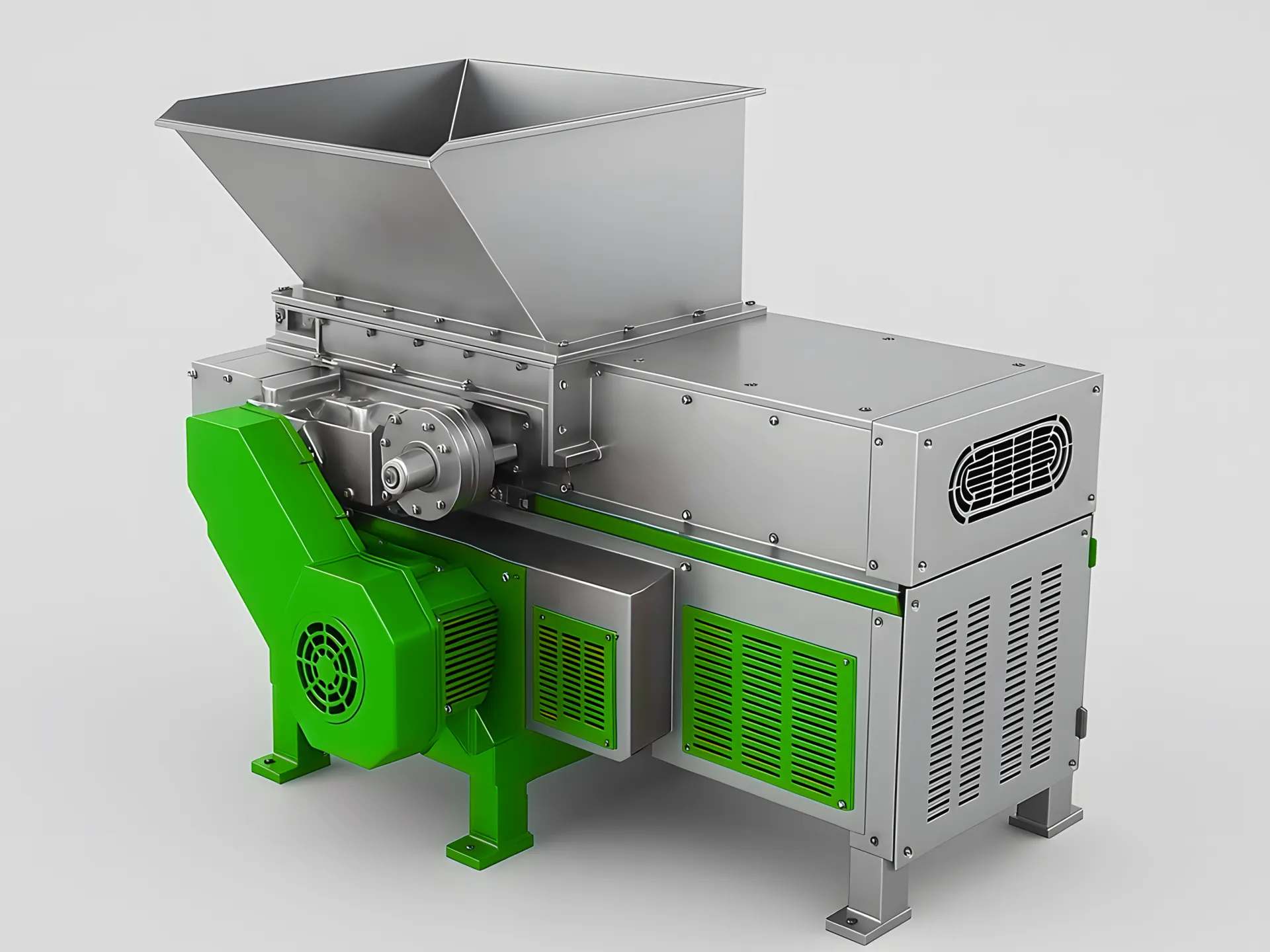

RTM RTMS series shredders follow the industry-standard single-shaft (single-rotor) layout: a slow-speed rotor, fixed counter-knives, a hydraulic pusher (ram) and a sizing screen. Material is continuously presented to the cutting zone until it meets the required size and discharges through the screen.

Best for: Rigid plastics (purge, lumps, runners, sprues, crates), wood waste & pallets, light production scrap, and mixed bulky items that benefit from a ram-fed cutting chamber.

What makes it different from twin-shaft machines: A standard single-shaft shredder produces a more controlled, screen-defined output—ideal as a primary or secondary shredder in a recycling line.

A standard single-shaft shredder is defined by its single rotor, ram-fed cutting chamber and sizing screen. These modules work together to deliver consistent discharge size and stable throughput.

Single Rotor

A slow-speed, high-torque rotor with knife pockets provides steady cutting and high resistance to shock loads—ideal for rigid plastics and bulky items.

Knife System

Rotary knives cut against fixed counter-knives to shear material efficiently. Knife arrangement and material options are selected for wear life and your feedstock.

Hopper & Hydraulic Ram

The hopper loads parts into the chamber while the hydraulic pusher presses material into the rotor for consistent bite—especially important for large, hollow or bulky pieces.

Screen & Discharge

A sizing screen controls the discharge size. Material circulates in the chamber until it can pass through the screen, producing a more uniform output.

Drive & Controls

Motor + gearbox drive the rotor; PLC logic can manage ram cycles, overload protection and auto-reverse to keep production stable and reduce downtime.

Material enters the cutting chamber through the hopper. The hydraulic ram pushes it into the rotor, where rotary knives cut against fixed counter-knives. Pieces remain in circulation until they can pass through the sizing screen, which controls the final discharge size and improves uniformity for downstream recycling.

Standard Single-Shaft Benefits:

- Screen-defined output size for consistent downstream processing

- Hydraulic pusher improves bite on bulky and rigid materials

- Low-speed, high-torque cutting reduces heat and dust

- Stable, automated operation with overload protection and auto-reverse

- Designed for continuous industrial duty with serviceable wear parts

| Feature | Single-Shaft Shredder | Double-Shaft Shredder |

|---|---|---|

| Primary Role | Controlled size reduction with a screen-defined output | High-torque pre-shredding / tearing for bulk reduction |

| Output Size Control | Yes (screen controls discharge size and uniformity) | Typically no screen; output is larger and less uniform |

| Typical Materials | Rigid plastics, wood waste, pallets, production scrap | Mixed waste, bulky items, film bundles, hollow plastics |

| Feeding & Control | Hydraulic ram feeds the rotor for consistent bite | Self-feeding dual rotors; aggressive pull-in |

| Best Use in a Line | Primary/secondary shredder before granulation or washing | Pre-shredder before single-shaft shredding or crushers |

| Operating Profile | Stable, consistent output; good for controlled production | High bulk reduction; best when uniform size is not required |

Watch how a standard single-shaft shredder produces a controlled, consistent output for recycling and waste volume reduction.

These are standard RTMS series configurations. For your material and target output, we can recommend rotor size, screen configuration, knife setup, and automation options.

| Model | RTMS-600 | RTMS-800 | RTMS-1000 | RTMS-1200 |

|---|---|---|---|---|

| Capacity (kg/h) | 300–500 | 500–800 | 800–1200 | 1200–1800 |

| Main Motor Power | 30 kW | 45 kW | 2 × 37 kW | 2 × 45 kW |

| Hydraulic Motor Power | 4 kW | 4 kW | 5.5 kW | 5.5 kW |

| Blade Material | SKD11 | SKD11 | SKD11 | SKD11 |

| Rotor Diameter (mm) | Φ400 | Φ400 | Φ450 | Φ500 |

| Rotational Speed (rpm) | 85 | 85 | 80 | 70 |

| Output Size (mm) | 400–600 | 600–800 | 800–1200 | 1500–2000 |

A standard single-shaft shredder is a ram-fed, single-rotor machine that cuts material against fixed counter-knives. A screen controls the discharge size, producing a consistent output that is easier to handle in downstream recycling.

Screen size is chosen based on your target output and downstream equipment. Smaller screens produce a more uniform output for granulation or washing lines; larger screens increase throughput for pre-sizing. Share your feedstock and target size and we’ll recommend the best configuration.

Yes. The hydraulic pusher (ram) presses bulky parts into the rotor, improving bite and throughput on rigid plastics, pallets and wood waste. For extremely large or mixed waste, a twin-shaft pre-shredder can be added upstream.

Both. Many recycling lines use a standard single-shaft shredder as a primary shredder for rigid plastics and wood. It’s also commonly used as a secondary shredder after a pre-shredder to achieve a more uniform, screen-defined output.

Routine maintenance includes knife inspection/rotation, counter-knife setting, screen inspection, lubrication, and checking hydraulic oil level and filters. We provide maintenance guidance and spare parts support for RTMS series machines.

All our recycling machines include a one-year limited warranty.

To get current pricing and lead times, please submit your request using the form below.

Comments are closed.