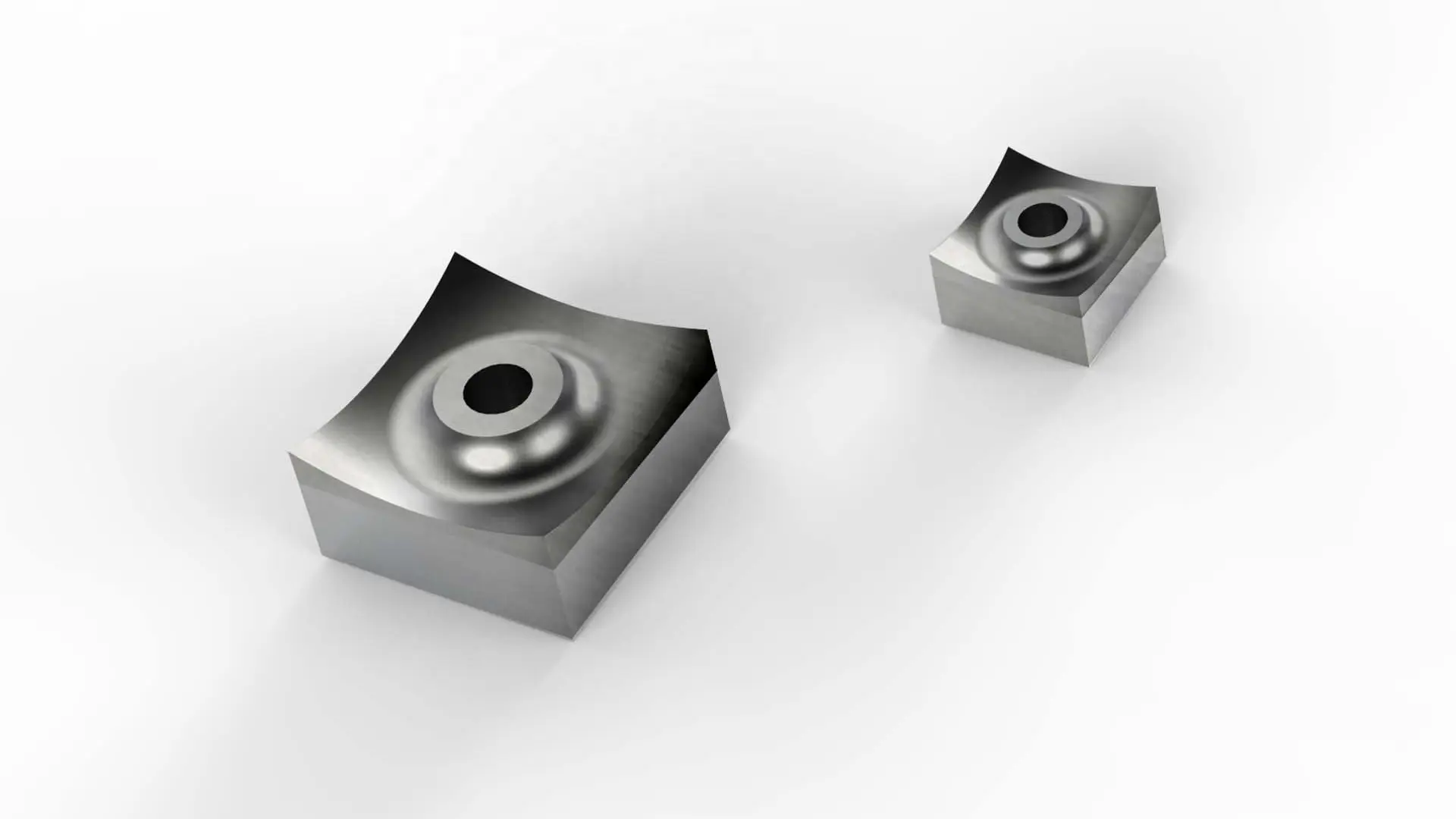

Shredder rotor knives are essential components in the recycling industry, particularly in the processing of plastics. The website of Rumtoo, a renowned manufacturer in this field, provides valuable insights into the quality and performance of their tungsten carbide inlaid shredder rotor knives. These knives are not just tools; they are the heart of the recycling process, playing a crucial role in ensuring efficiency and effectiveness.

Key Features of Rumtoo Shredder Rotor Knives

High-Quality Material and Construction:

The knives are made from premium materials like D2, SKD11, DC53, etc., ensuring durability and longevity. The use of tungsten carbide inlay further enhances their wear resistance.

Advanced Heat Treatment:

The knives undergo a triple tempered, vacuum heat treatment process. This sophisticated treatment ensures that the knives maintain their hardness (HRC56-58) and toughness, which are critical for their performance in harsh recycling environments.

Customization and Precision:

Rumtoo offers customized services, selecting the most suitable tool material and employing the most accurate heat treatment process. This customization is based on the specific application and performance requirements of the customer, ensuring that each knife meets the unique needs of different recycling operations.

Wide Application:

These knives are primarily used in plastic recycling machines. Their design and construction make them ideal for this purpose, providing good wear resistance and toughness, which are essential for processing various types of plastics.

Commitment to Quality:

Rumtoo large vacuum heat treatment furnaces, forging, and CNC machining facilities underline their commitment to producing first-class quality knives. This commitment is evident in the popularity of their products across various markets, including Europe, America, Australia, Japan, and Korea.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.