Introduction:

In the realm of substantial waste management and recycling material processes, the shear type double shaft shredder stands out as an indispensable piece of equipment. This blog delves deep into the unique design features, versatile applications, and essential maintenance and operation tips of this shredder to attract potential customers and industry professionals.

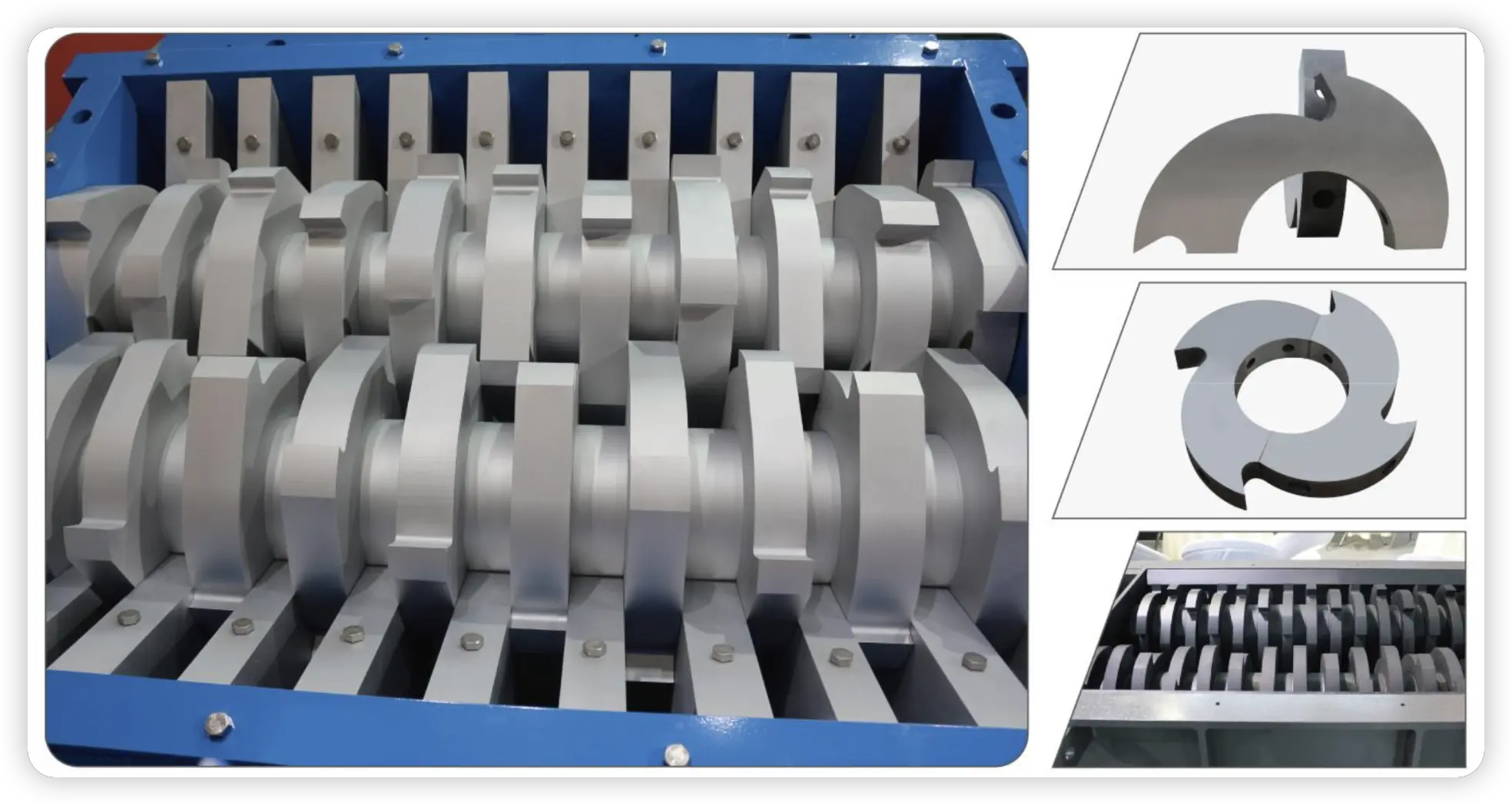

Design Features:

The shear type double shaft shredder is engineered to tackle the most challenging shredding tasks. Featuring a dual-shaft operating system, this machine efficiently processes a variety of materials including plastics, metals, tires, and wood. Each shaft is equipped with robust shear blades that precisely cut materials under high torque, reducing the risks of material entanglement and jamming, ensuring long periods of stable operation.

• Motor and Reducer Connection: A belt pulley connection between the motor and the reducer allows for progressive deceleration, effectively protecting both components.

• Transmission System: The use of couplings in the transmission system alleviates the force of backlash, ensuring overall structural stability.

• Tool Versatility: Depending on the material, operators can choose from integrated or separate tools, as well as various tool thicknesses, offering great versatility.

• Electrical System: Equipped with a Siemens PLC control system, the shredder is simple to operate and safe to run.

Specification

| Shredder Model | Shaft Diameter (mm) | Moving Knife Qty. (pcs) | Maximum Capacity (kg/h) | Motor Power (KW) | Chamber Size (L x W) mm | Host Weight (kg) | Dimensions (L x W x H) mm |

|---|---|---|---|---|---|---|---|

| XB-0600 | 320 x 45 | 12 | 800 | 18.5 x 2 | 600 x 780 | 3800 | 2960 x 880 x 2300 |

| XB-0800 | 320 x 45 | 16 | 1000 | 22 x 2 | 800 x 780 | 4800 | 3160 x 900 x 2400 |

| XB-01000 | 400 x 50 | 20 | 2000 | 45 x 2 | 1000 x 880 | 7000 | 3360 x 980 x 2500 |

| XB-01200 | 400 x 50 | 24 | 3000 | 55 x 2 | 1200 x 880 | 8500 | 3760 x 1000 x 2550 |

| XB-01600 | 500 x 65 | 24 | 5000 | 75 x 2 | 1600 x 960 | 12000 | 4160 x 1080 x 2600 |

| XB-02000 | 600 x 77 | 28 | 8000 | 90 x 2 | 2000 x 110 | 20000 | 4600 x 1220 x 2800 |

Applications:

The shear type double shaft shredder is widely used across various industries, including waste management, recycling, electronic waste disposal, and construction waste treatment. Its applications extend to:

• Plastic Waste: Efficient at shredding plastic containers and bottles.

• Metal Disposal: Ideal for metal cans and barrels.

• Rubber and Automotive Parts: Handles tires, car bumpers, barriers, and circuit boards with ease.

• Household Appliances: Capable of breaking down old washing machines, refrigerators, and other large appliances.

• Organic Material: Plays a crucial role in the size reduction of materials for biofertilizer production.

Operation and Maintenance Tips:

To ensure optimal performance and longevity of your shear type double shaft shredder, regular maintenance and proper operation are essential. Before operating, check that all machine parts are intact and all safety measures are in place. Regularly replacing blades and lubricating key components significantly enhances machine efficiency and reduces the likelihood of failures. Additionally, developing a detailed maintenance schedule helps promptly identify and address potential issues.

Conclusion:

The shear type double shaft shredder is a formidable tool in modern industry for material processing. Its powerful capabilities and adaptability make it the equipment of choice in waste management and material recycling fields. Proper maintenance and operation can provide long-term reliability and efficiency, aiding businesses in achieving both economic benefits and environmental goals.