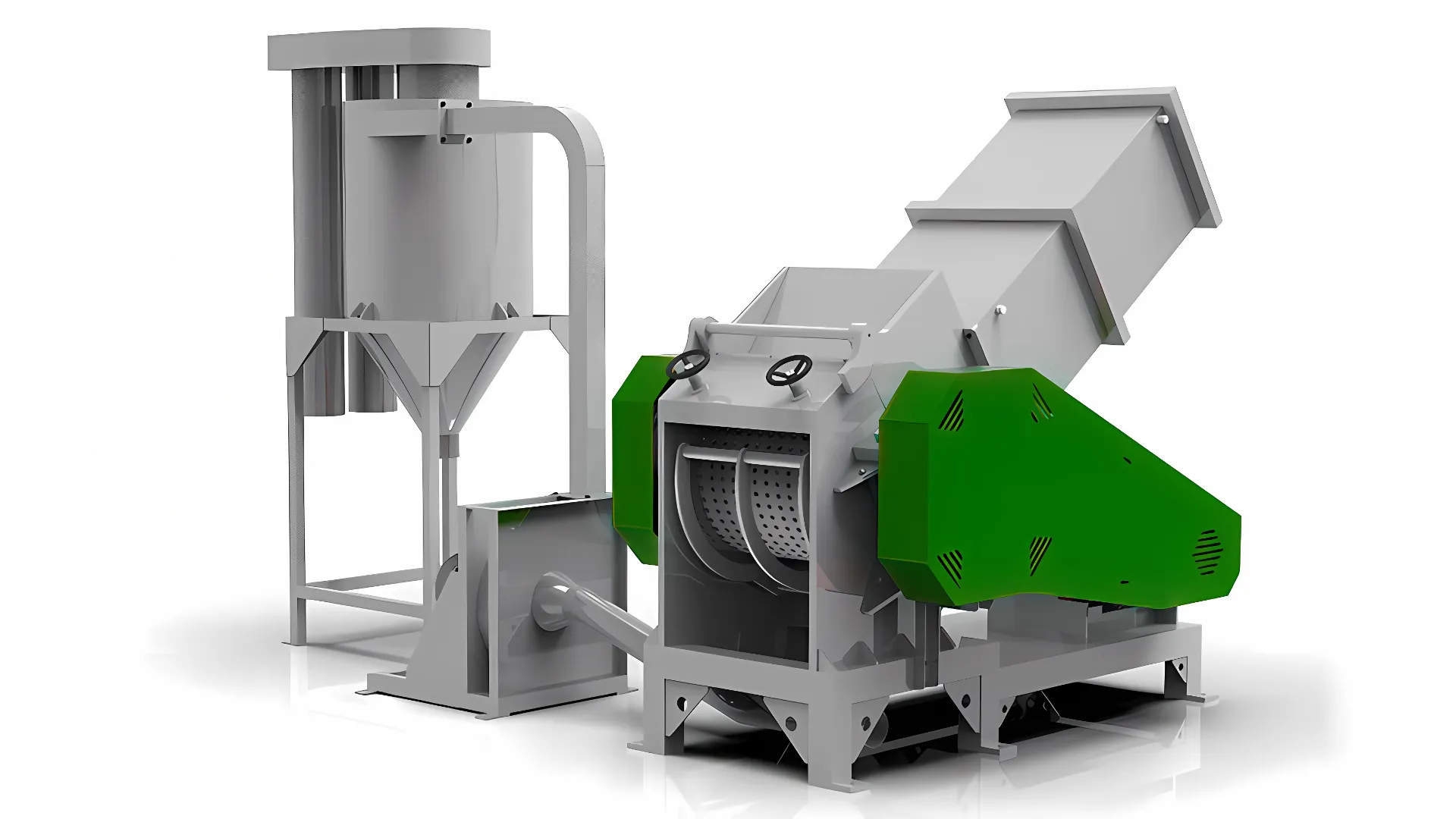

Dealing with bulky PVC pipe scrap can be a major headache for recycling operations. Our heavy-duty horizontal PVC pipe crusher is engineered to efficiently reduce the volume of your PVC pipe waste, simplifying downstream processing and boosting your recycling efficiency.

Introduce:

Conquer Any PVC Pipe:

This powerful crusher effortlessly handles a wide range of PVC pipe sizes and wall thicknesses, transforming them into manageable pieces for further processing.

Built for Demanding Environments:

- Robust Construction: Crafted from high-grade steel, our crusher boasts exceptional durability and resistance to wear and tear, ensuring long-lasting performance in demanding recycling environments.

- Powerful Crushing Force: Equipped with a robust motor and hardened cutting blades, our crusher delivers the force needed to break down even the toughest PVC pipe effortlessly.

- Horizontal Design: The horizontal configuration allows for easy feeding of long pipe sections and optimizes material flow for continuous operation.

Benefits That Make a Difference:

- Increased Efficiency: Significantly reduce the volume of PVC pipe scrap, optimizing storage space and streamlining downstream processes.

- Enhanced Safety: Eliminate the hazards associated with manually handling large, unwieldy pipe sections.

- Cost Savings: Minimize transportation and storage costs by reducing the volume of your PVC scrap.

- Versatile Applications: Ideal for a wide range of applications, including PVC pipe recycling, construction and demolition waste processing, and more.

Features:

- Adjustable Size Reduction: Customize the output size of crushed PVC material to meet the specific needs of your downstream processing equipment.

- Low Noise Operation: Engineered to minimize noise pollution, creating a safer and more comfortable working environment.

- Easy Maintenance: Designed for simple maintenance and cleaning, ensuring maximum uptime and productivity.

Applications:

• Recycling Plants:Used primarily in plastic recycling facilities to break down large PVC pipes into smaller pieces that are easier to handle and process.

• Manufacturing and Production Waste Management:Helps manage and recycle production waste in factories that produce PVC pipes, thereby reducing waste and promoting sustainability.

• Material Recovery Facilities (MRFs):Plays a crucial role in sorting and processing waste in facilities that handle multiple types of recyclable materials.

Specification:

| Model | Power (kW) | Speed (rpm) | Extrusion Capacity (kg/h) | Screw Diameter (mm) | Driving Power (kW) | Heating Power (kW) | Hopper Volume (m³) | Output (kg/h) |

|---|---|---|---|---|---|---|---|---|

| 560/630 | 22/37 | 2/4 | 10/10 | 500/550 | 0.37/0.37 | 3/4 | 0.3/0.5 | 250/350 |

| 730/830 | 55/75 | 4/4 | 10/10 | 600/800 | 0.37/0.55 | 5.5/11 | 0.5/1 | 450/700 |

| 1000/1300 | 90/110 | 4/6 | 10/10 | 900/1200 | 0.75/1 | 15/18.5 | 1/2 | 850/1200 |

Explanation of Columns:

- Model: Indicates the model number of the machine.

- Power (kW): The electrical power of the machine’s motor.

- Speed (rpm): Rotations per minute of the machinery parts.

- Extrusion Capacity (kg/h): The capacity of material that can be processed per hour.

- Screw Diameter (mm): Diameter of the screw mechanism used in the machine.

- Driving Power (kW): Power needed for the driving mechanism of the machine.

- Heating Power (kW): Power used by the heating elements.

- Hopper Volume (m³): Volume of the hopper where materials are loaded.

- Output (kg/h): The output capacity in kilograms per hour.

Inquire

warranty

All machines and parts to be free from defect for 1 year.

Contact us today to learn more about how we can customize a solution to meet your specific needs and help you achieve optimal efficiency and profitability.