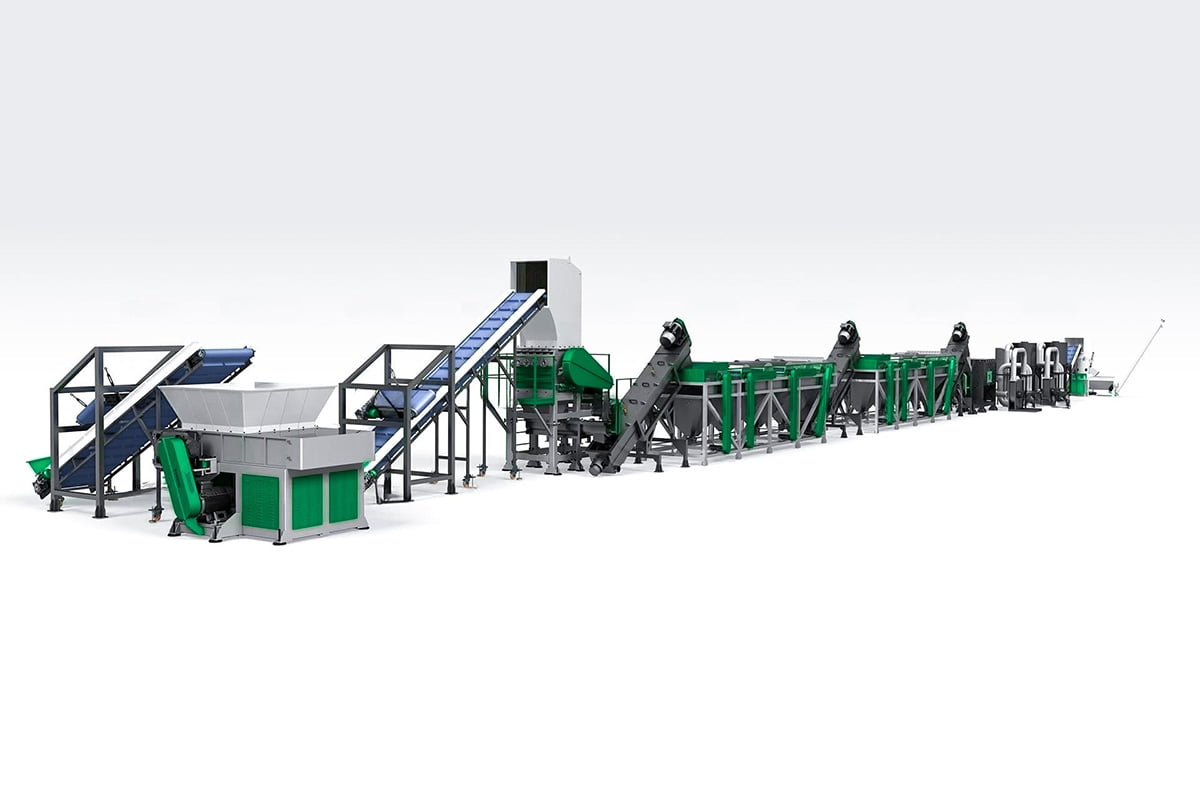

PP/PE Film Shredding & Densifying Line

An integrated washing and densifying solution engineered for recyclers and pelletizing plants. Built for light, contaminated, and wet PE/PP films, it runs shredding → wet granulation → sink–float separation → squeezing & densifying to raise bulk density and cut residual moisture for steady, trouble‑free pelletizing.

Key Data Highlights

-

Low Final Moisture Mechanical squeezing plus heat exchange drives down residual moisture for direct pelletizing.

-

Significant Densification Bulk density rises substantially, cutting storage and freight costs and stabilizing feeding.

-

Flexible Capacities Multiple configurations with full customization to match your throughput goals.

How It Works: Four-Step Densifying Process

- Shredding

Wear-resistant shredder opens film bales and reduces volume for stable feeding.

- Wet Granulation

High-speed knives with process water cut and wash in one step to remove dirt and oils.

- Sink/Float Separation

Water tank separates light film from heavy contaminants to raise purity.

- Squeezing & Densifying

Simultaneous dewatering and heat exchange increase bulk density and reduce final moisture.

Process Flow Overview

The integrated line combines shredding, wet granulation, density separation, and squeezing/densifying in a compact footprint tuned for film recycling.

Core Benefits

- High-Efficiency Densification

Reduces fluffiness and raises bulk density for steadier, more uniform feeding.

- Low Final Moisture

Mechanical squeezing with heat exchange minimizes secondary drying and shortens the process.

- Energy Efficient

Optimized process design and motor selection deliver lower kWh per ton.

- Modular Configuration

Integrates with existing washing lines; flexibly combines shredding, granulation, separation, and densifying modules.

- Built to Last

Wear-resistant contact surfaces handle high-contamination films with reduced downtime.

- Smart Controls

One-touch start/stop, interlocks, and fault alarms cut manual intervention and maintenance.

From Pain Points to Performance

Target the chronic bottlenecks in film recycling with a process engineered to stabilize feeding, moisture, and contamination before pelletizing.

Inline shredding, wet granulation, and densifying lift bulk density so films convey smoothly and feed extruders without surging.

Mechanical squeezing and controlled heat exchange deliver pelletizer-ready moisture levels, cutting bubbles and improving surface quality.

Wet granulation plus sink–float separation remove fines and organics early, easing filtration load and lowering consumable spend.

Modular layouts, high-efficiency drives, and centralized controls shrink footprint, reduce kWh per ton, and simplify operator routines.

Applications

- Agri film / greenhouse film

Light films with high dirt content such as mulch and greenhouse films.

- Packaging / stretch / shrink film

Common warehouse and logistics films; densify and feed directly to pelletizing.

- Woven bags / FIBC trims

PP/PE mixes benefit from separation and densifying to improve purity and stability.

- Shopping / garbage bags

Thin, wet, post-consumer films fit the wash + densify process well.

- Washing line upgrades

Use as a standalone densifier to upgrade dewatering and feeding on existing lines.

- Plant offcuts

Clean production offcuts can be densified directly to boost throughput.

Technical Specifications

| Model | RUM-200 | RUM-500 | RUM-1000 |

|---|---|---|---|

| Operation | 2-3 | 2-3 | 2-3 |

| Installation power | 160-200kW | 200-240kW | 400-450kW |

| Knife material | SKD11 | SKD11 | SKD11 |

| Capacity(kg/h) | 200 | 500 | 1000 |

Note: Parameters can be customized. Final configuration and throughput depend on your material and process goals.

What Sets Us Apart

| Criteria | Our Densifying Line | Conventional Washing + Centrifugal Dewatering |

|---|---|---|

| Final moisture | Lower residual moisture; ready for pelletizing | Often needs extra drying; variable results |

| Bulk density | Substantial increase; steadier feeding | Limited improvement; feeding remains erratic |

| Energy & footprint | Integrated and compact layout | Fragmented machines; larger footprint |

| Contamination handling | Wet granulation + sink–float synergy | Higher load on upstream washing |

| Maintenance | Wear-resistant parts; easier upkeep | More wear points; frequent service |

| Automation | One-touch start/stop with interlocks | Weaker system interlocks |

Frequently Asked Questions

Film is light and fluffy, which makes storage, transport, and pelletizer feeding difficult. Densifying raises bulk density and lowers moisture so material feeds steadily into the extruder.

It’s densified irregular chunks/strands or flakes (not uniform pellets). The key is the right bulk density and moisture for extruder feeding; geometry depends on material and process.

Yes. Shredding, wet granulation, and sink–float work together to remove mud, paper, and other contaminants—ideal for post-consumer and agricultural films.

This is pre-processing: washing, dewatering, and densifying. A pelletizer is downstream—it melts, filters, and cuts the final pellets. This line prepares stable, low‑moisture feedstock for pelletizing.

Both. You can purchase the squeezing/densifier as a standalone upgrade for existing washing lines or as a turnkey line with shredding, granulation, sink–float, and densifying tailored to your capacity targets.

Customer Testimonials

Once feeding stabilized, filtration pressure held steady. Moisture control is far easier and pellet quality is more consistent across shifts.

The wash + densify configuration finally lets us handle post-harvest films with mud and sand; downstream extruders run without clogging.

Turnkey delivery, on-site training, and the recommended screen packs boosted uptime. Integration with legacy equipment was smooth.

Warranty & Installation

- 1-Year Limited Warranty

All our recycling machinery comes with a limited warranty, ensuring peace of mind with your purchase.

- Expert Installation Support

We offer installation packages where our engineers can travel to your facility to guide you through the setup process. All our products can be customized to customer requirements.

Get a Custom Solution & Quote

Share your material mix, contamination level, and capacity goals. Our engineers will map the optimal shredding, washing, and densifying modules with timelines and budget.

Comments are closed.