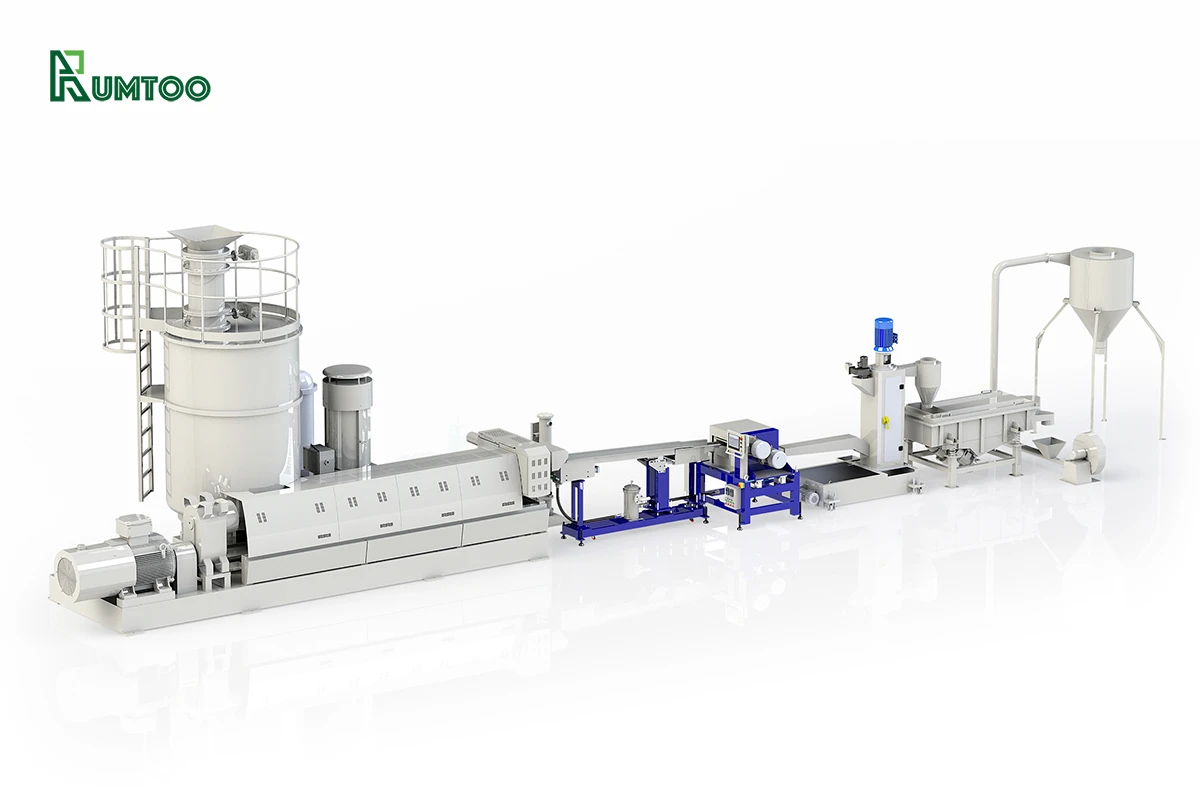

Plastic Pelletizing Machine

The ultimate solution for converting plastic waste into high-quality pellets, designed for efficiency and durability across various recycling applications.

Technical Parameters

- Machine Components: Conveyor belt, cutter compactor shredder, extruder, pelletizing unit, water cooling unit, drying unit, silo tank

- Processing Capacity: 300-2000 kg/h

- Voltage: Customized based on request (For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz...)

- Material Compatibility: HDPE, PE, PP, BOPP, and more

- Recycled Pellet Size: Adjustable between 3mm-5mm

- Dimensions: Customizable based on facility requirements

Key Features

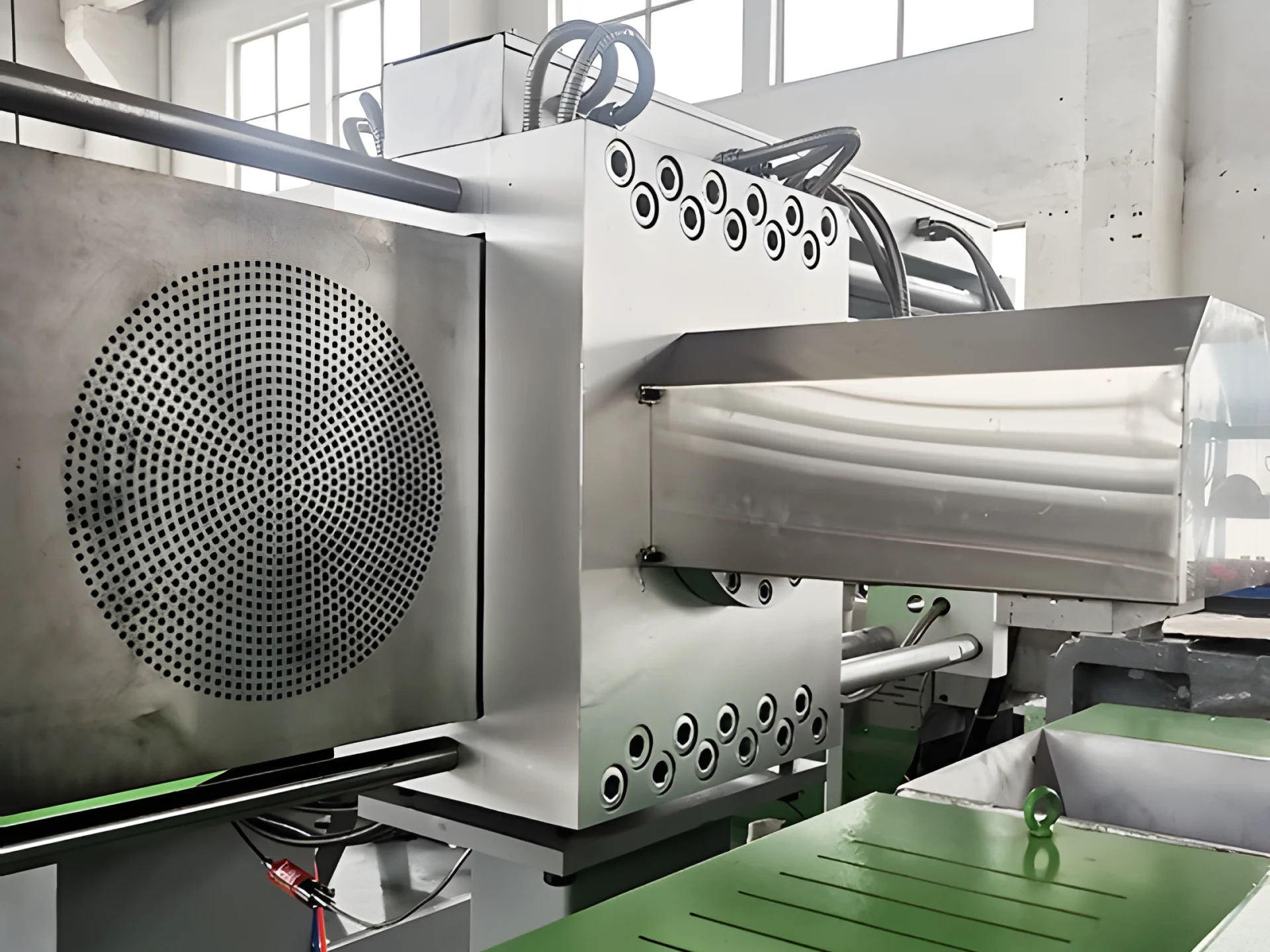

Advanced Degassing System

Triple degassing zones remove ink, moisture, and volatiles, ensuring high-quality pellet output.

Integrated Cutter-Compactor

The machine includes a cutter-compactor to pre-process materials, ensuring consistent feeding and output quality.

Automatic Pelletizing Control

Automatically adjusts pelletizing speed and blade pressure for uniform pellet size and reduced manual intervention.

Wide Material Compatibility

Capable of recycling a wide range of materials such as HDPE, LDPE, PP, and more, including heavily printed and laminated films.

Usage

Printed and Laminated Films

Recycles heavily printed and laminated plastic films, ideal for post-industrial and post-consumer waste.

HDPE, LDPE, PP Pellets

Processes various plastic materials into high-quality pellets, suitable for use in film blowing, pipe extrusion, and injection molding.

Customizable Configurations

The pelletizing machine can be customized to meet specific recycling facility requirements, from capacity to dimensions.