In the world of plastic recycling, the PP/PE Film Pellet Machine stands as a beacon of innovation. This machine, designed to granulate recycled materials like HDPE, LDPE, LLDPE, PP, PS, PET, PC, and others, is a testament to the advancements in recycling technology.

The Power of the PP/PE Film Pellet Machine

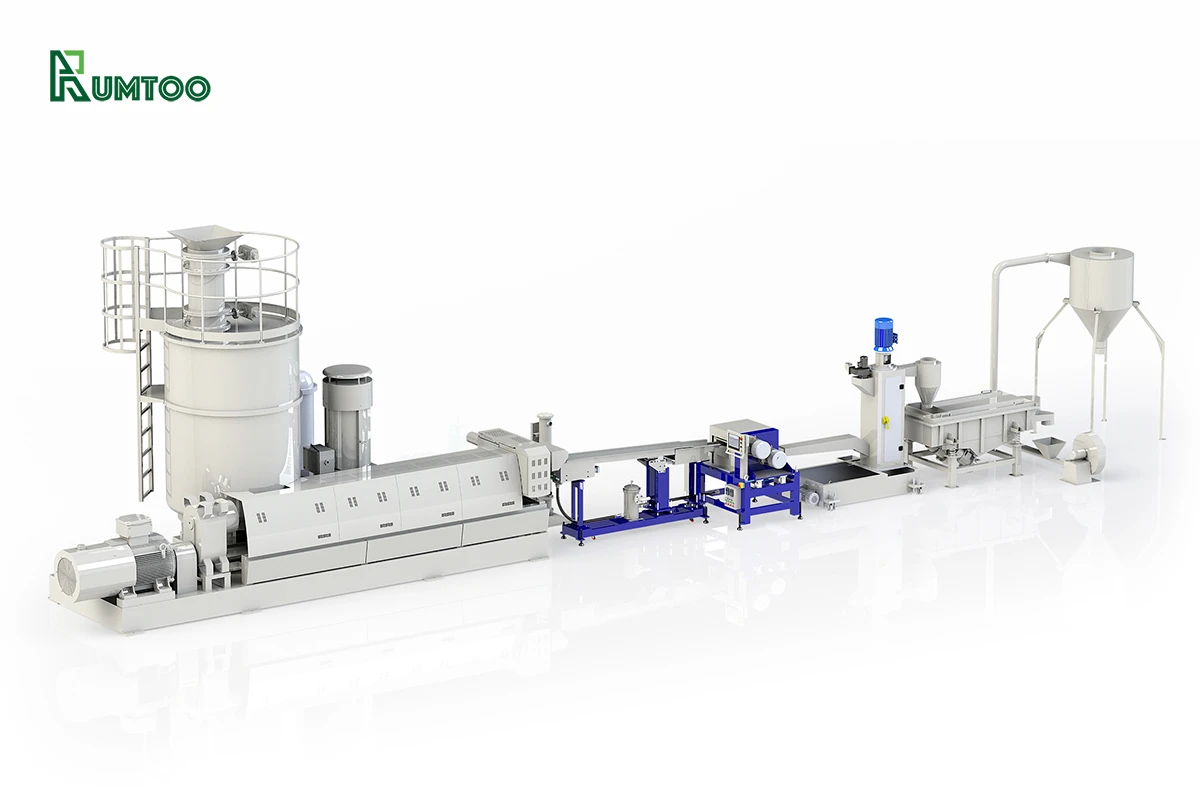

The PP/PE Film Pellet Machine is a marvel of modern engineering. It employs a variety of screw designs to ensure continuous operation during production. This machine is equipped with pneumatic conversion and a robust wind-blowing system, coupled with water cooling and a de-watering machine. These features work together to produce high-quality pellets that meet stringent industry standards.

The machine’s stainless steel storage container is adjustable, accommodating different quantities of materials. With a capacity ranging from 200kg/h to 1000kg/h, the PP/PE Film Pellet Machine is versatile enough to cater to businesses of all sizes.

The Plastic Pelletizing Process

The plastic pelletizing line is a key component of the recycling process. It transforms waste plastics into reusable pellets, which can be used to manufacture new plastic products. The process involves several stages:

- Shredding/Crushing: The plastic waste is reduced in size by shredding or crushing it into smaller pieces.

- Washing and Drying: The shredded plastic is washed to remove contaminants, then dried to eliminate any remaining moisture.

- Extrusion: The clean, dry plastic is melted in an extruder and forced through a die.

- Pelletizing: The extruded plastic is cooled and cut into small pellets.

- Cooling and Drying: The pellets are cooled and dried again to solidify and remove any remaining moisture.

- Screening/Classifying: The pellets are screened to separate any dust or undersized pellets.

- Packaging: Finally, the pellets are packaged and ready for transport or to be used in the production of new plastic products.

The Environmental and Economic Impact

The PP/PE Film Pellet Machine is not just a piece of machinery; it’s a solution to the pressing issue of plastic waste. By transforming waste PP/PE films into reusable plastic pellets, this machine reduces the amount of plastic waste, decreases environmental pollution, and lessens the demand for new raw materials.

From an economic perspective, the PP/PE Film Pellet Machine offers significant advantages. The recycled plastic pellets can be used in production to create new plastic products, saving raw material costs and improving production efficiency. This machine is a testament to the potential of recycling and its importance in reducing environmental pollution.

Conclusion

The PP/PE Film Pellet Machine is an innovative solution to the problem of plastic waste. It’s a significant tool for environmental protection and economic development. By promoting this machine and raising public awareness about environmental protection, we can make our world a better place.

For the latest prices and lead times, please send us a message using the form below.

Main Technical Parameter

| Model | RMC2-85 | RMC2-100 | RMC2-120 | RMC2-150 | RMC2-160 | RMC2-180 |

|---|---|---|---|---|---|---|

| Capacity(KG/H) | 100-200 | 200-300 | 300-400 | 500-600 | 700-800 | 800-1000 |

| L/D | 1:33 | 1:33 | 1:33 | 1:36 | 1:36 | 1:36 |

| Install Power(KW) | 110 | 135 | 160 | 310 | 370 | 520 |

| Compactor Power(KW) | 37 | 45 | 55 | 110 | 132 | 180 |

| Main extruder Power(KW) | 55 | 75 | 90-110 | 185 | 220 | 280-315 |

| Screen exchanger | 160mm | 200mm | 250mm | 350mm | 400mm | 500+mm |

| Staff requirement | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 |

| Overall size(L*W*H) | 9*5*4 | 10*5*4 | 12*5*4 | 13*6*4 | 13*6*4 | 13*6*4 |

We are confident that our PP/PE Film pellet machine can help you achieve your production goals and deliver high-quality pellets that meet your clients’ needs.

Warranty

All recycling machines come with a 1 year limited warranty.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.