Plastic Film Densifier for PE/PP Film

Struggling with high energy costs and extruder feeding issues from wet, fluffy film? Our Plastic Film Densifier creates high-density, dry granules that cut operational expenses by over 40% and boost your line’s profitability.

Get a Custom SolutionWhat Is a Plastic Film Densifier?

A Plastic Film Densifier mechanically dewaters and compacts washed PE/PP films into dry, free‑flowing granules ideal for feeding a pelletizing extruder. It replaces energy‑intensive thermal drying and solves unstable feeding from fluffy film.

Also known as a squeezer dryer or film agglomerator, it integrates high‑pressure squeezing and controlled frictional heating to reduce moisture to 1–3% typical while increasing bulk density 3–5×. This directly improves extruder stability and output.

Unlock Peak Efficiency & Profitability

This single machine is the ultimate alternative to traditional centrifugal and thermal dryers, delivering multiple advantages for your plastic film recycling line.

Drastically Lower Energy Costs

Reduce energy consumption by over 40%. Our efficient mechanical squeezing process eliminates the need for power-hungry hot air drying systems.

Achieve Higher Extruder Output

The dense, free-flowing granules ensure stable and consistent feeding, solving clogging issues and increasing your pelletizing throughput by up to 20%.

Produce Superior Quality Pellets

By reducing moisture content to less than 5% (typically 1-3%), you guarantee high-quality, bubble-free recycled pellets with higher market value.

Simplify Your Workflow

This integrated dewatering and densifying solution replaces two separate machines, saving valuable floor space and minimizing your maintenance workload.

Plastic Film Densifier: From Washed Film to Pellet‑Ready Granules

Our three-step mechanical squeezing and agglomerating process ensures maximum efficiency without material degradation.

1. Direct Feeding

Washed film direct from your recycling line is conveyed into the machine’s inlet, handling high initial moisture with ease.

2. Mechanical Squeezing

A specialized high-speed screw applies immense pressure, physically forcing water out through a screen in a highly efficient process.

3. Frictional Agglomerating

Controlled friction generates heat, forming dense, uniform granules perfect for pelletizing.

The Plastic Film Densifier is specially designed to work in tandem with the recycling line’s washing and extrusion-pelletizing components. This seamless integration is the key to maximizing the output and efficiency of your entire operation.

Applications & Materials

The Plastic Film Densifier handles post‑consumer and post‑industrial streams and prepares them for stable extrusion.

- PE film (LDPE/LLDPE), printed film, stretch & shrink wrap

- PP woven bags, raffia, jumbo bags (FIBCs) after washing

- Agricultural film, greenhouse film with residual moisture

- Label film offcuts and packaging film reclaim

- Integration with Plastic Film Washing Line and Plastic Pelletizers

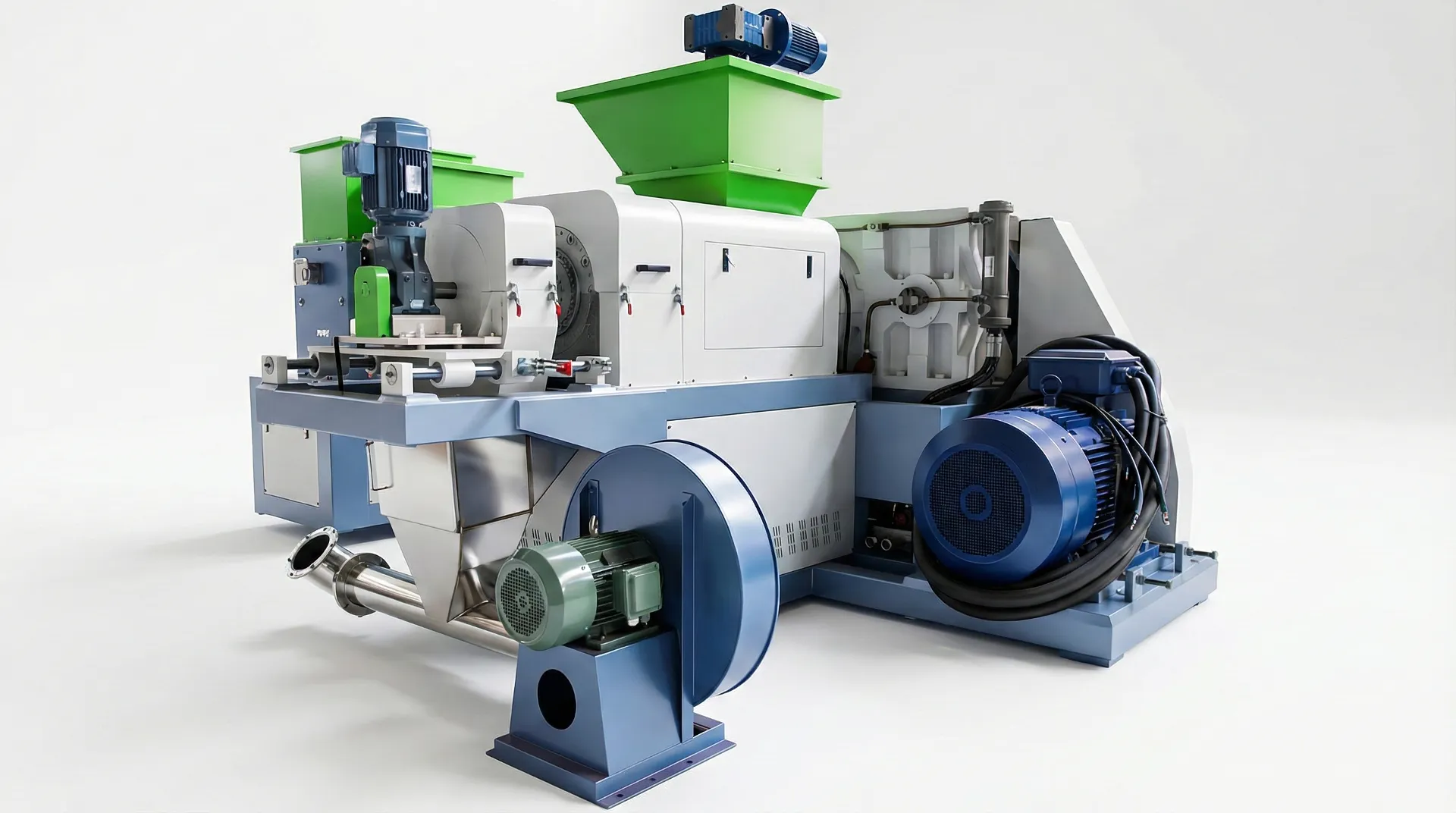

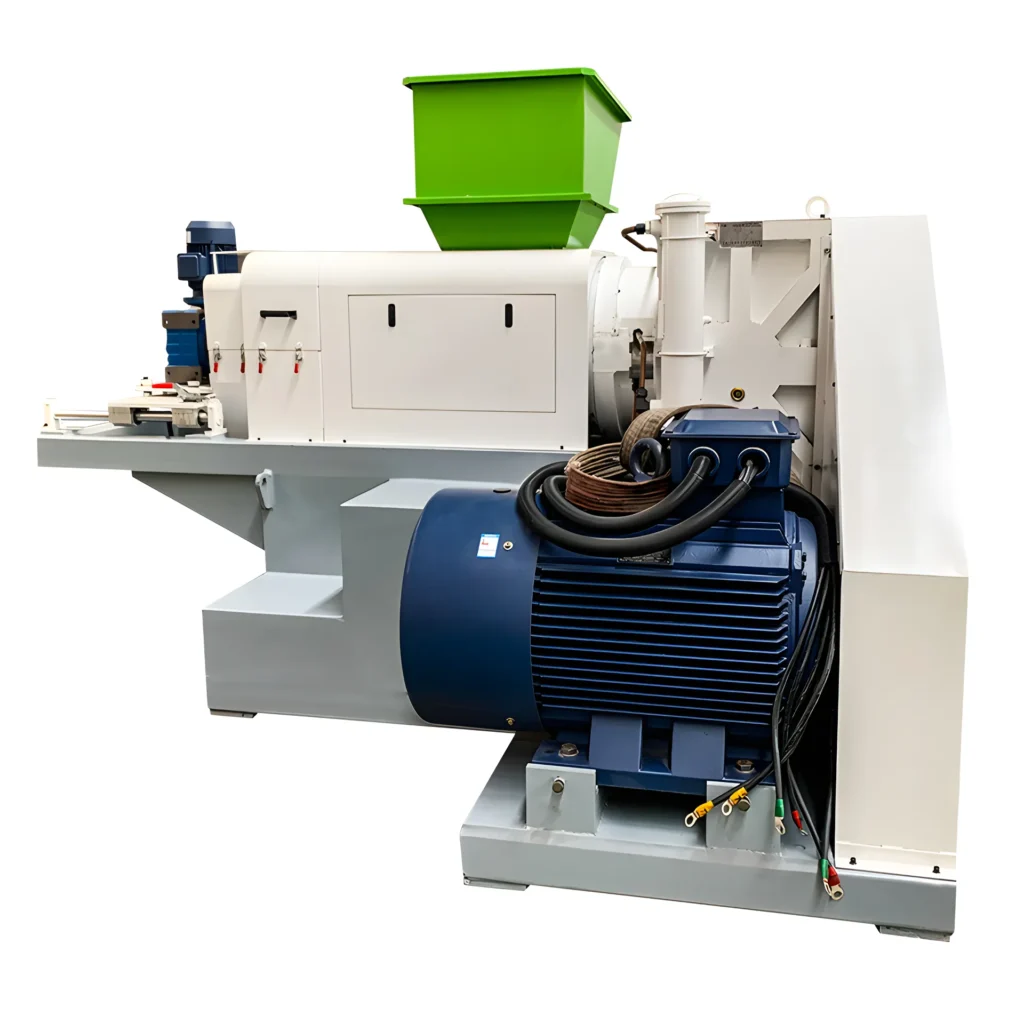

Equipment in Detail

Explore the robust construction and intelligent design of our Plastic Film Densifier.

Plastic Film Densifier Specifications

Engineered for performance and reliability. All specifications can be customized for your specific material and output requirements.

| Applicable Materials | Post-consumer PE film, post-industrial LDPE, PP woven bags, agricultural film |

| Throughput Capacity | 300 – 1500 kg/h (Model-dependent) |

| Main Motor Power | 90 – 250 kW (Varies by model) |

| Final Moisture Content | < 5% (Typically 1-3%) |

| Core Components | Wear-Resistant SKD-11 Alloy Screw, Reinforced Gearbox, Siemens/ABB Motor |

| Provided Services | On-site Engineering, Custom-Engineered Solutions, Spare Parts Support |

Model Options

Choose a model that matches your washing line and pelletizer throughput.

| Model | Capacity (kg/h) | Main Motor | Final Moisture | Notes |

|---|---|---|---|---|

| RT‑D300 | 300–500 | 90 kW | 1–3% | Compact, fits small lines |

| RT‑D500 | 500–800 | 132 kW | 1–3% | Best‑seller for PE film |

| RT‑D800 | 800–1200 | 185 kW | 1–3% | High‑throughput, stable feeding |

| RT‑D1200 | 1200–1500 | 220–250 kW | 1–3% | Large line integration |

Why Densifier vs. Centrifugal or Thermal Drying?

A Plastic Film Densifier combines dewatering and densifying in a single step, cutting energy and simplifying the line.

| Method | Energy Use | Moisture | Feeding Behavior | Notes |

|---|---|---|---|---|

| Plastic Film Densifier | Low | 1–3% typical | Stable, free‑flowing granules | Replaces two machines |

| Centrifugal Dryer | Medium | 5–10% typical | Fluffy, bulkier | Often needs thermal stage |

| Thermal Hot‑Air Dryer | High | 3–5% typical | May remain fluffy | Higher OPEX, footprint |

Your Questions Answered

This machine is a specialized dewatering and pre-processing unit. Its main goal is to dry material perfectly for a pelletizing extruder. A standard agglomerator’s main goal is to create a high-density flake as a final product, often with less control over the drying process.

It is designed to handle material coming directly from a thorough washing line. While its primary role is dewatering, it is robust enough for films with residual print and dirt. The ultimate quality of your final pellets will always depend on the effectiveness of your washing stage.

Maintenance is minimal. The main wear components are the screw and barrel, built from highly durable, wear-resistant alloys. Routine checks include gearbox oil and screen cleaning. We provide a comprehensive maintenance schedule and spare parts list with every unit.

PE film (LDPE/LLDPE), PP woven bags/raffia, stretch & shrink film, agricultural film and other washed flexible packaging. For heavily contaminated inputs, pair it with our Plastic Film Washing Line.

Yes. The densified, low‑moisture granules feed consistently into plastic pelletizing lines, improving output and reducing melt pressure fluctuations.

In most cases 1–3% with proper washing and drainage. We generally guarantee < 5% to cover variations in input material and operation.

Related Products

Build a complete film recycling and pelletizing solution around your densifier.

Get a Free Workflow Analysis & Custom Quote

Each machine includes a 1-year limited warranty and on-site installation support. Contact us today to improve your recycling plant’s efficiency with a tailored solution.