In the lead-acid battery industry, the production process begins with transforming raw lead ingots into lead granules. Traditionally, lead is primarily melted for casting or cutting into granules. These granules are then processed into lead powder using ball mill machines.

To streamline this process, we have developed an automatic production equipment for cold pelletizing of lead ingots. This equipment revolutionizes the traditional method of melting lead for granule casting and enables automated production of cold lead granules. The entire operation is controlled by a PLC system. This innovation addresses several issues associated with the traditional process, such as high pollution and energy consumption. Moreover, it offers significant advantages, including enhanced environmental protection, energy efficiency, and increased production efficiency, all of which benefit the lead-acid battery industry significantly.

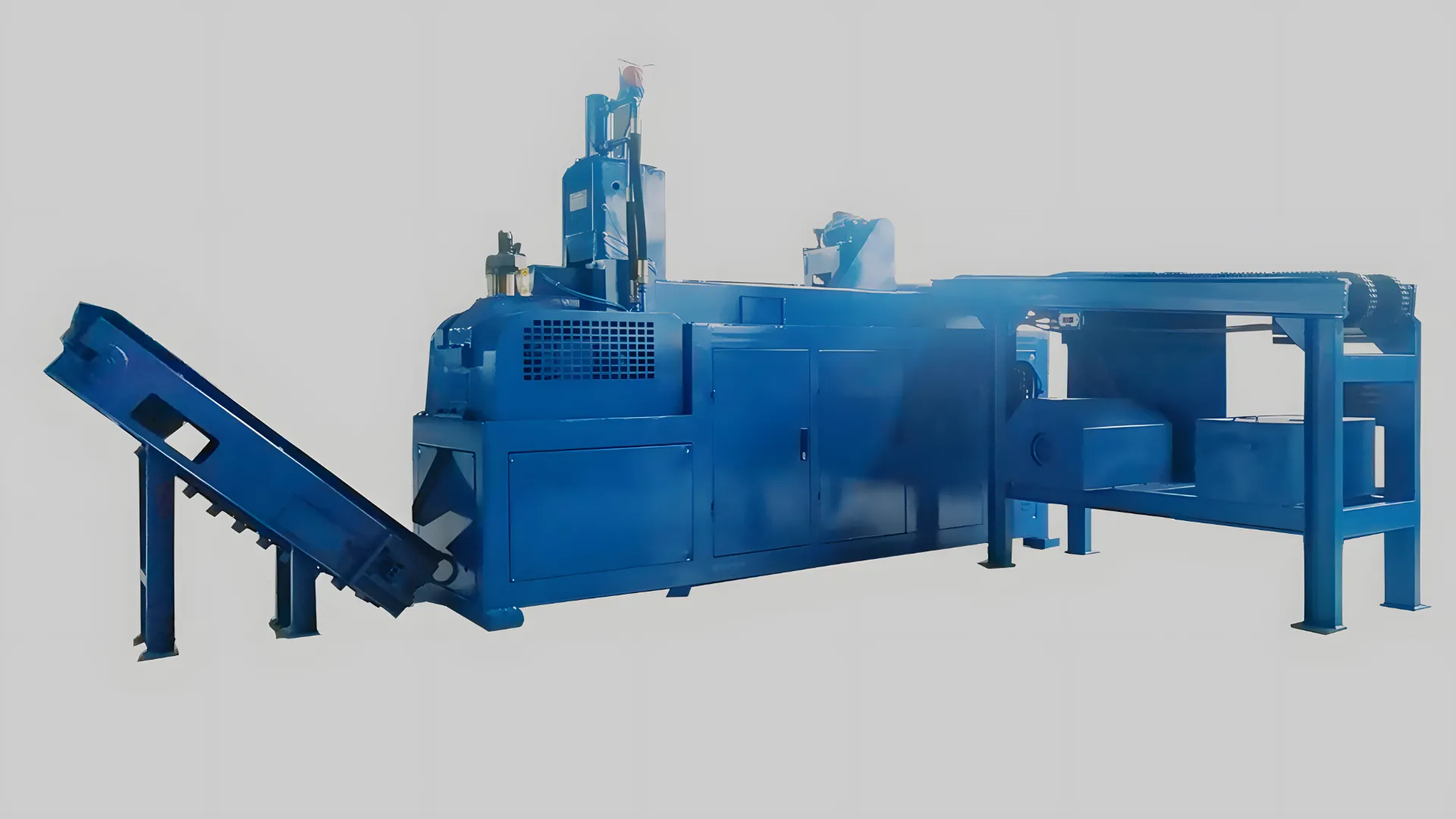

Introduce:

This lead ingot cold cutting machine is specifically designed to cut lead ingots into lead granules, featuring a lead ingot conveying mechanism, an extrusion mechanism, a lead strip conveying mechanism, a strip dividing mechanism, a granule cutting mechanism, and a lead granule conveying mechanism. Initially, the lead ingot conveying mechanism transports the lead ingots to the extrusion mechanism, which compresses the ingots multiple times to form lead strips. These strips are then transported out by the lead strip conveying mechanism and further conveyed to the granule cutting mechanism by the strip dividing mechanism. The granule cutting mechanism cuts the lead strips into granules, which are finally output by the lead granule conveying mechanism. This design allows the cold-cutting machine to process lead ingots in a cold state, effectively avoiding the harmful lead fumes that can be produced during the melting process of lead ingots.

Specifications:

1. Voltage: 380 V, three to four lines, 50 Hz.

2. Installed Power: 28.8 kW/h.

3. Actual Power Usage: 15 kW/h or less.

4. Single Equipment Set: Utilizes 1 standard lead ingot (45 kg per ingot). Suitable for granulation needs of one 24T ball mill machine or two 14T ball mill machines.

5. Granulation Size: From 25 x 25 x 17 mm to 20 mm.

6. Grain Weight: 75 to 100 g ± 15 g.

7. Production Capacity: 2.5 T/h to 2.75 T/h.

8. Applicable Air Pressure: Not less than 0.4-0.7 MPa.

9. Suitable Water Pressure: 0.2 MPa.

10. Water Temperature: 10°C to 25°C.

11. Granulation Equipment Export Height: 350 m.

12. Hydraulic Oil for Equipment: Great Wall brand anti-wear hydraulic oil L-HM46.

13. Equipment Dimensions:

• Main Unit: 3028mm x 1040mm x 2100mm.

• Auxiliary Unit: 2200mm x 760mm x 1450mm.

• Lead Grain Scraper Conveyor: 1450mm x 350mm x 1250mm.

14. Total Machine Weight: Approximately 4 T.