Definition and Basic Function

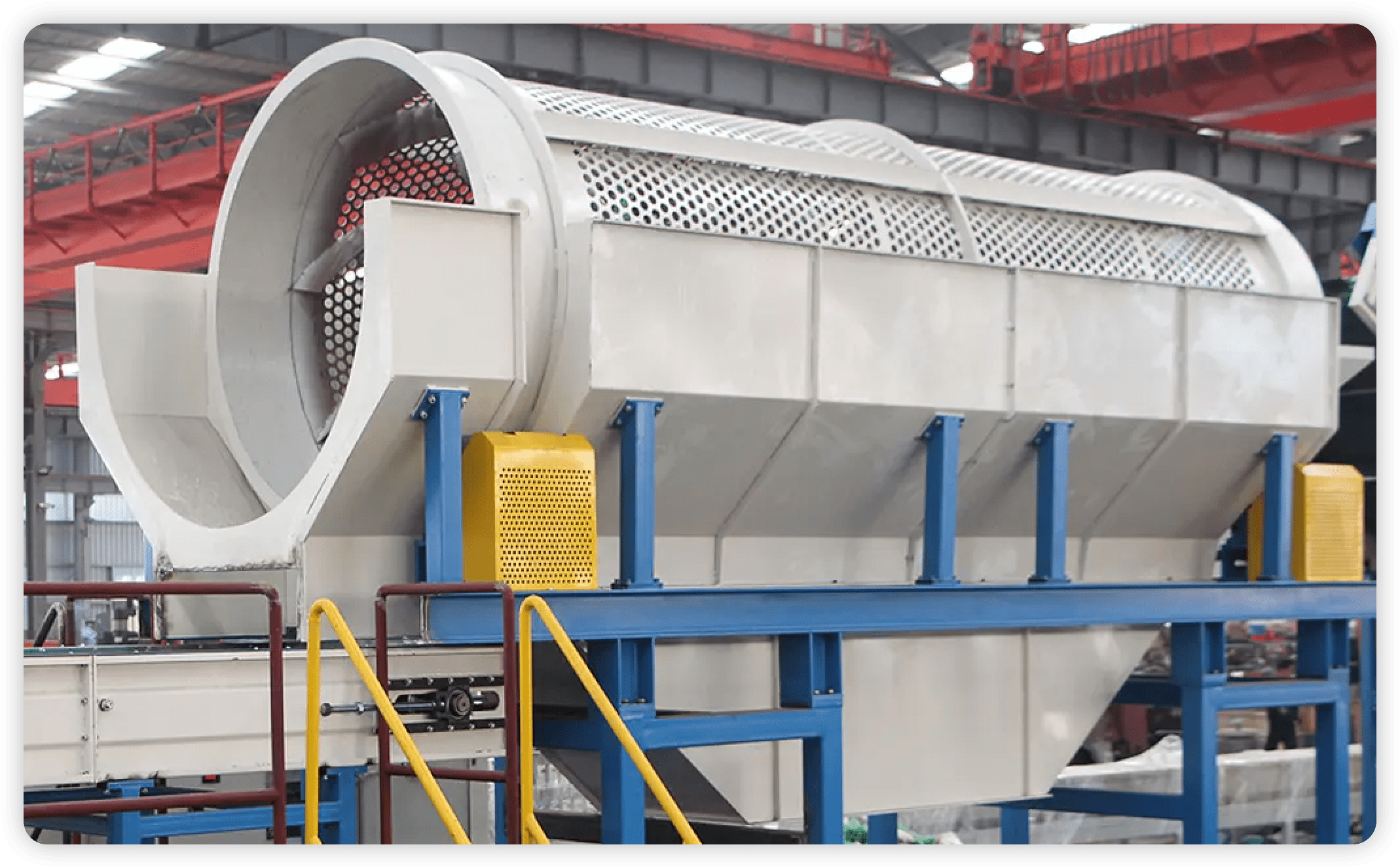

A Trommel screen, also known as a rotary screen, is a mechanical screening machine used to separate materials, mainly in the mineral and solid-waste processing industries. It consists of a perforated cylindrical drum that is normally elevated at an angle at the feed end. The basic function of a Trommel screen is to screen out differing sizes of materials as they pass through a rotating screen.

How It Works

The Trommel screen works by rotating the drum, allowing smaller particles to fall through the holes while larger particles exit at the other end of the drum. This screening process is simple yet highly effective, and it can be used to separate a wide range of materials including soil, compost, municipal solid waste, and minerals.

Key Components

- Drum: The main body of the Trommel screen, perforated for screening.

- Motor and Gearbox: Provide the necessary power for the drum to rotate.

- Support Structure: Offers stability and height for the Trommel.

- Inlet and Outlet Points: Where the material enters and exits the Trommel.

- Screen Panels: Attached to the inside of the drum; these can vary in size and material depending on the application.

Applications

- Waste Processing: Used in municipal solid waste (MSW) facilities to separate waste components.

- Mineral Processing: Helps in segregating different minerals and materials in the mining industry.

- Agriculture: Used for screening compost and soil, crucial in organic farming practices.

- Recycling Industry: Sorts recyclable materials from other debris.

Advantages

- Efficient Separation: Capable of handling a high volume of materials.

- Versatility: Suitable for a variety of applications and materials.

- Low Maintenance: Simple design leads to lower operational and maintenance costs.

- Environmental Friendly: Helps in recycling processes, reducing landfill waste.

Conclusion

The Trommel screen is a highly versatile and efficient piece of equipment, pivotal in various industries for the separation of materials. Its simplicity, efficiency, and effectiveness make it an indispensable tool in waste management, recycling, mining, and agricultural processes.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.