Introduction

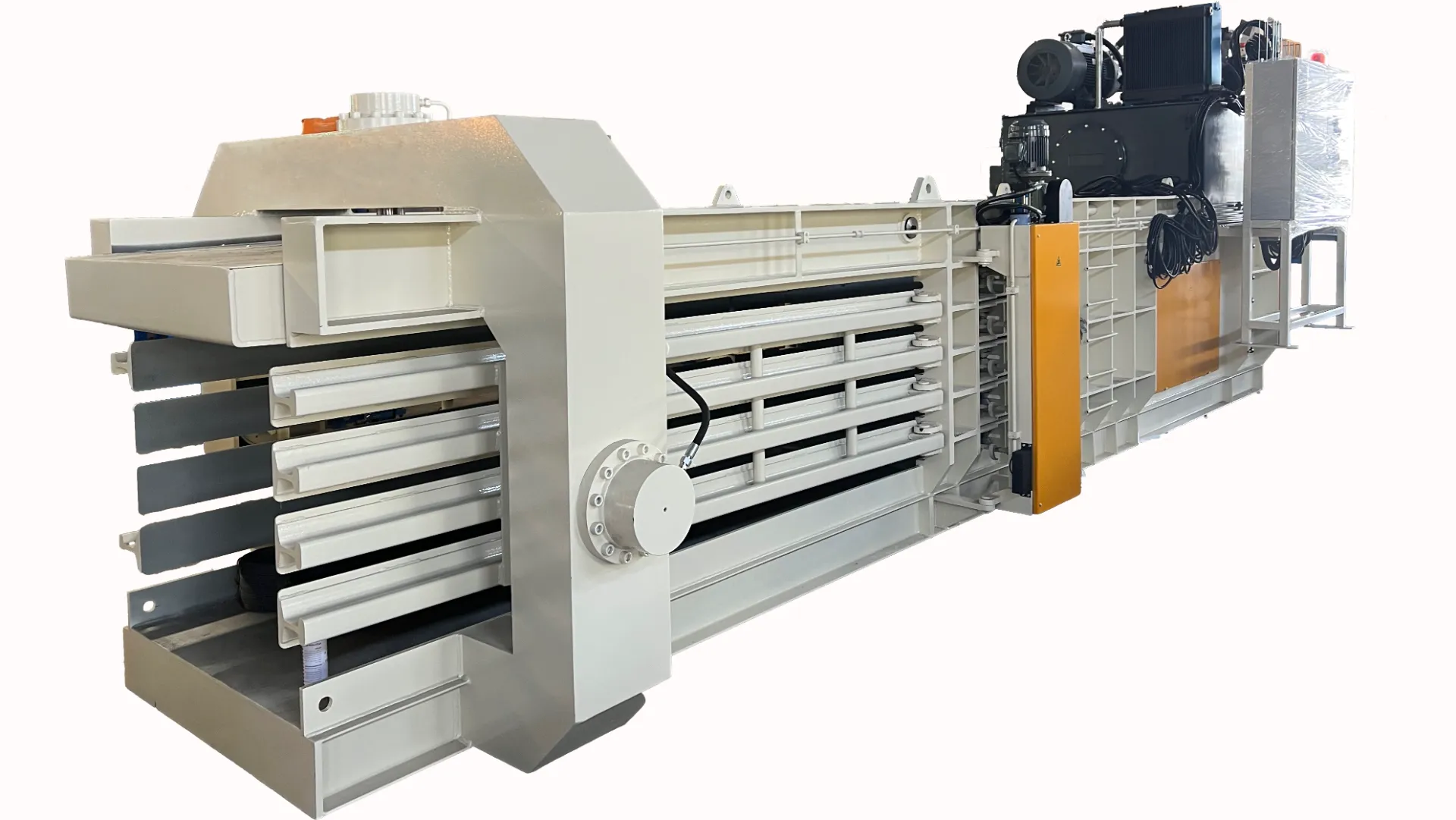

Our state-of-the-art large-sized automatic horizontal baler is expertly designed for efficient waste management and recycling. Perfect for carton factories, packaging factories, printing factories, paper-making factories, waste disposal stations, waste recycling stations, logistics centers, and other environments generating significant waste, our baler is built to handle diverse materials including waste paper boxes, cardboard, plastic, PET bottles, and organic materials. With a focus on automation and efficiency, this machine simplifies operations and minimizes manual labor, ensuring your operations are both cost-effective and environmentally friendly.

Features

• High Efficiency and Automation: The baler operates on a fully automatic system that manages compressing, strapping, wire cutting, and bale ejecting. Enhanced by a PLC control system, it ensures a high degree of automation and accuracy.

• Energy-Saving Design: Equipped with advanced German hydraulic technology and dual motors for starting and boosting, the baler optimizes energy use and reduces operational costs.

• Ease of Use: Features such as one-button operation, touch screen controls, and an optional automatic feeding conveyor maximize user-friendliness and operational efficiency. The touch screen panel allows for easy setting adjustments and real-time feedback.

• Customization and Precision: Users can adjust bale lengths and record precise data on bale output, catering to specific requirements. The machine also includes a cooling system to maintain optimal hydraulic oil temperatures, even in high ambient conditions.

• Robust and Reliable Construction: The heavy-duty frame requires only a flat surface for installation. Our unique cutter and frame designs ensure longevity and consistent performance, even under continuous use.

After-Sales Service

• 24/7 Support: Our dedicated service line is available around the clock to assist with any inquiries or issues.

• Responsive Communication: We guarantee that all emails will be responded to within 10 hours, ensuring you always have the support you need.

• Parts and Maintenance: We provide all necessary machine parts at ordinary prices along with professional guidance. Our team is always ready to assist with maintenance and operational queries.

• Continuous Improvement: We actively collect customer feedback on after-sale service to continually improve our offerings and your experience.

FAQs

1. What materials can the baler process?

• It can process a wide range of materials including paper, cardboard, plastics, and textiles, making it highly versatile for various industries.

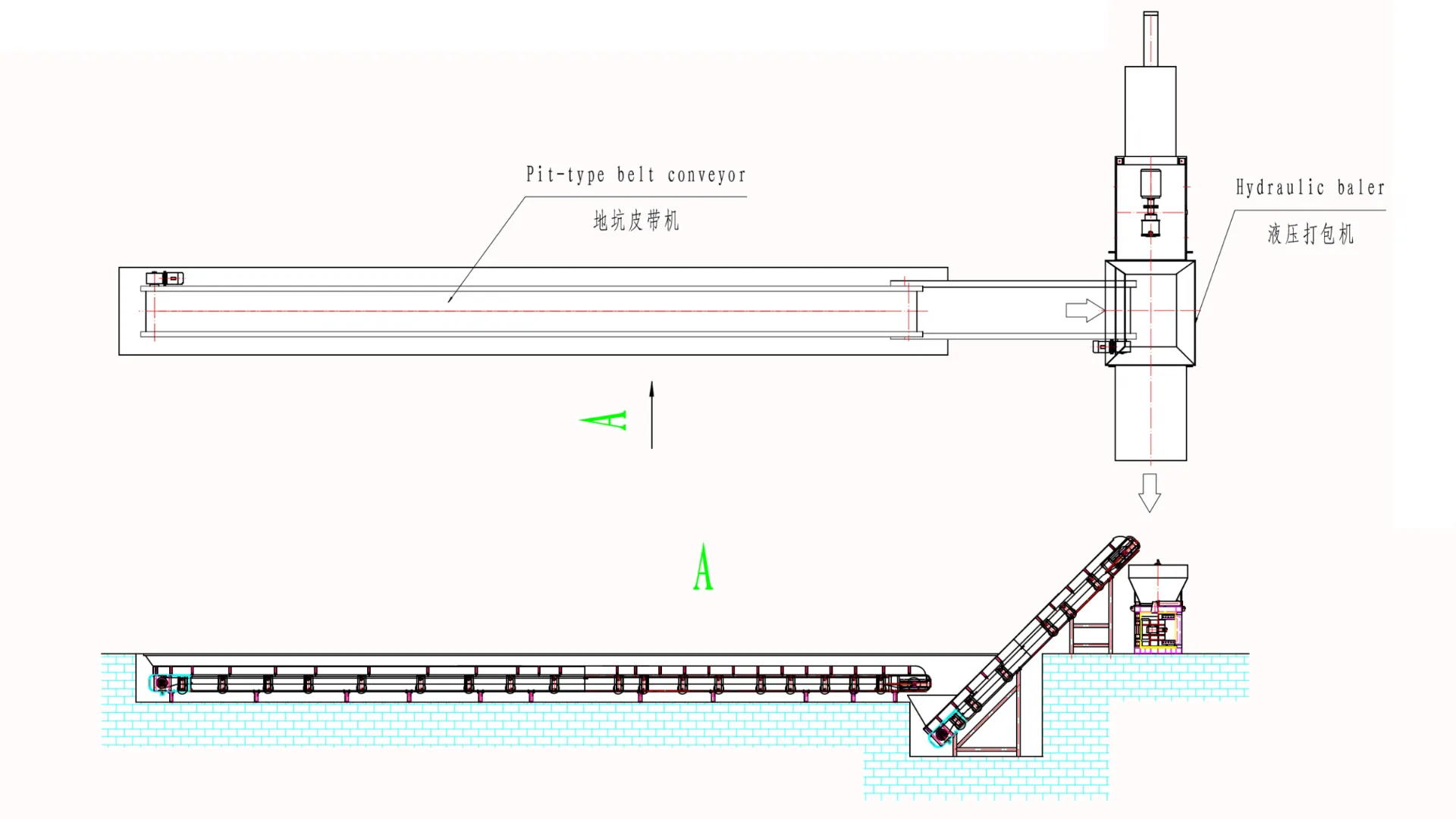

2. How does the automatic feeding conveyor enhance the machine’s efficiency?

• The conveyor optimizes material feeding by automatically starting or stopping based on the material level in the hopper, which enhances speed and maximizes output without manual intervention.

3. What are the energy-saving features of the machine?

• Our baler features a booster motor to save power and uses advanced hydraulic technology for efficient energy use, reducing both environmental impact and operational costs.

4. How easy is it to maintain the baler?

• The baler is designed for easy maintenance, featuring a PLC program for automatic fault diagnosis and a simple frame for easy access and repair. We also offer detailed graphic operation instructions to facilitate routine checks and maintenance.