PLASTIC RECYCLING SOLUTIONS

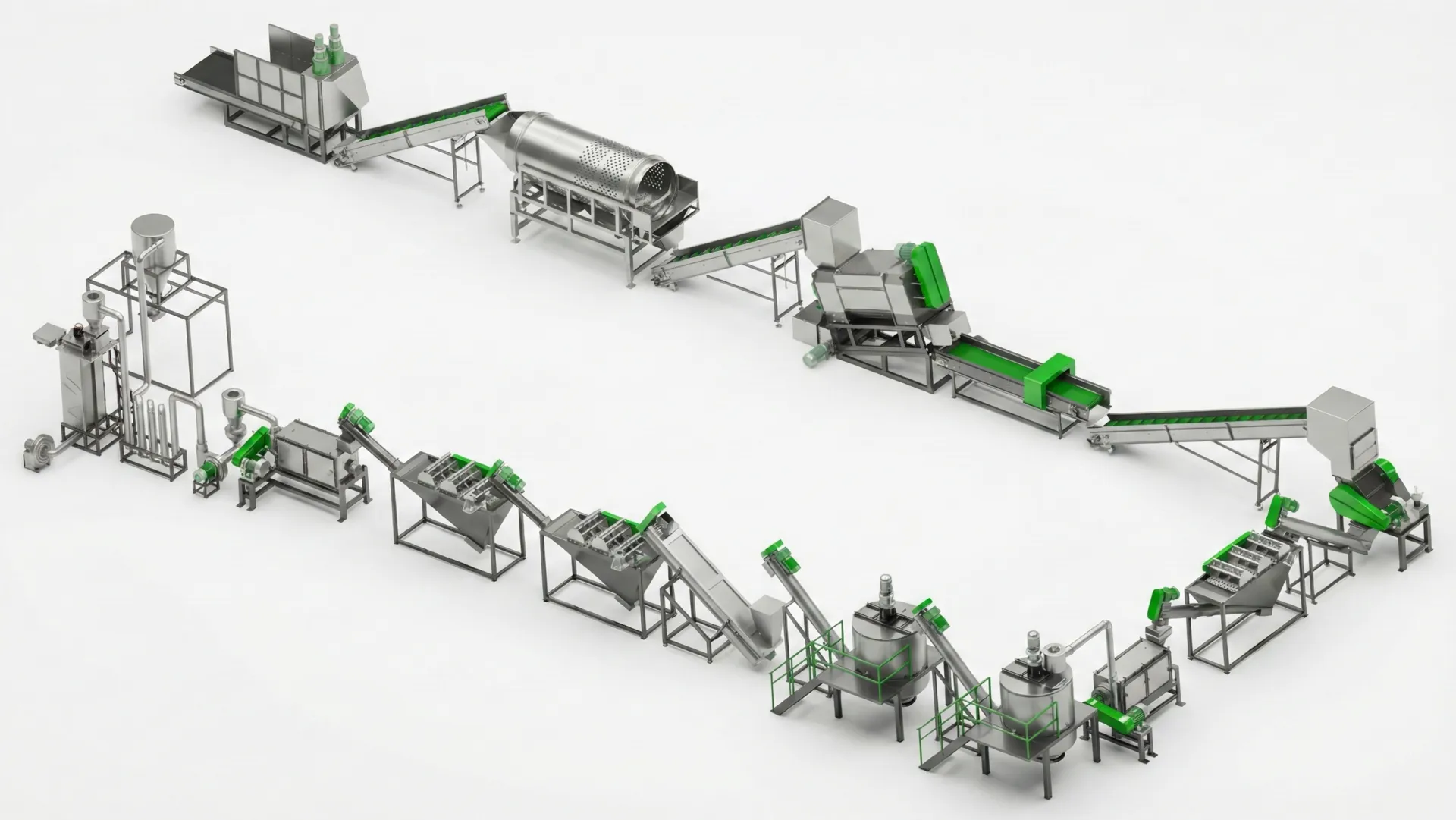

Our state-of-the-art technology enables efficient processing of various types of plastics, ensuring maximum recovery and minimal waste. From shredders to granulators, we offer a full range of machines that handle everything from collection and sorting to reprocessing and pelletizing.

Key Features & Benefits

Advanced Recycling Technology

Our plastic recycling machines use advanced recycling technology, efficiently converting plastic waste into high-quality granules.

Learn MoreCompact and Modular Design

Our recycling machines feature a compact, modular design, ideal for facilities with limited space. This allows for easy integration.

Learn MoreUser-Friendly Interface

Equipped with a user-friendly interface, our machines simplify operation, ensuring smooth and efficient recycling processes.

Learn MoreRobust Material Handling

Our machines come with a robust material handling system capable of managing a wide range of plastic types and sizes.

Learn MoreEnergy Efficiency

Designed with energy efficiency in mind, our machines reduce operational costs and carbon footprints, helping you meet environmental goals.

Learn MoreFull Support & Maintenance

We offer comprehensive support and maintenance services to ensure optimal performance and longevity of your equipment.

Learn MoreOur Recycling Systems

PET Bottle Recycling System

Automated washing and pelletizing line for PET bottles, ensuring high purity and efficient recovery.

View System

PP/PE Recycling Washing Line

Complete washing solutions designed for contaminated PP/PE films and crushed plastics.

View System

Rigid Plastic Washing Line

Specialized cleaning system for rigid plastics like HDPE bottles, PVC pipes, and hard scraps.

View System

Hazardous Plastic Recycling

Safe and compliant processing solutions for hazardous plastic waste containers and materials.

View System

Tire Recycling Machine

Turn waste tires into valuable rubber crumb and powder with our efficient tire recycling lines.

View SystemMaterials We Recycle

PET Bottles

PP/PE Films

Rigid Plastics

Tires & Rubber

Hazardous Waste

Mixed Plastics

Frequently Asked Questions

What types of plastic can your machines process?

Our machines are capable of processing a wide range of plastics including PET, PE, PP, PVC, OPS, EPS, and PA. Depending on your material's condition (film, rigid, woven), we customize the washing or pelletizing line for optimal results.

What is the capacity range of your washing lines?

We offer washing lines with capacities ranging from 500 kg/h up to 5000 kg/h. For pelletizing lines, capacities typically range from 200 kg/h to 1000 kg/h per single unit.

Do you offer installation and training services?

Yes, we provide comprehensive installation supervision and operator training. Our engineers can travel to your site to ensure the line is set up correctly and your team is confident in operating the machinery.

Can I customize the machine to fit my factory layout?

Absolutely. We provide custom engineering solutions tailored to your specific factory footprint and processing requirements. Our design team works with you to optimize the layout for efficiency.

Ready to Optimize Your Recycling Process?

Whether you are starting a new plant or upgrading existing equipment, our experts are here to help you find the best solution for your needs.

Contact Us for a Quote