Plastic Film Washing Line Advanced Recycling System

Delivering efficient, sustainable plastic film recycling while meeting the growing demand for premium reprocessed pellets. The line handles polypropylene (PP), polyethylene (PE), and mixed post-consumer films with consistent output quality.

Beyond our standard plastic film washing line capacities (500–3000 kg/h), we engineer turnkey systems for large-scale or specialised requirements, transforming loose or baled films into valuable pellets.

Core Workflow at a Glance

A streamlined 3-stage approach ensures excellent cleanliness and low moisture, ready for pelletising.

-

Shredding / Wet Granulation Reduce film to uniform pieces to prevent tangles and enable consistent washing downstream.

-

Friction Washing + Separation Intensive friction removes labels, organics and dirt; sink-float separates by density.

-

Multi-stage Drying Centrifugal and thermal drying (or screw press) lowers moisture for stable pelletising.

See the Process in Action

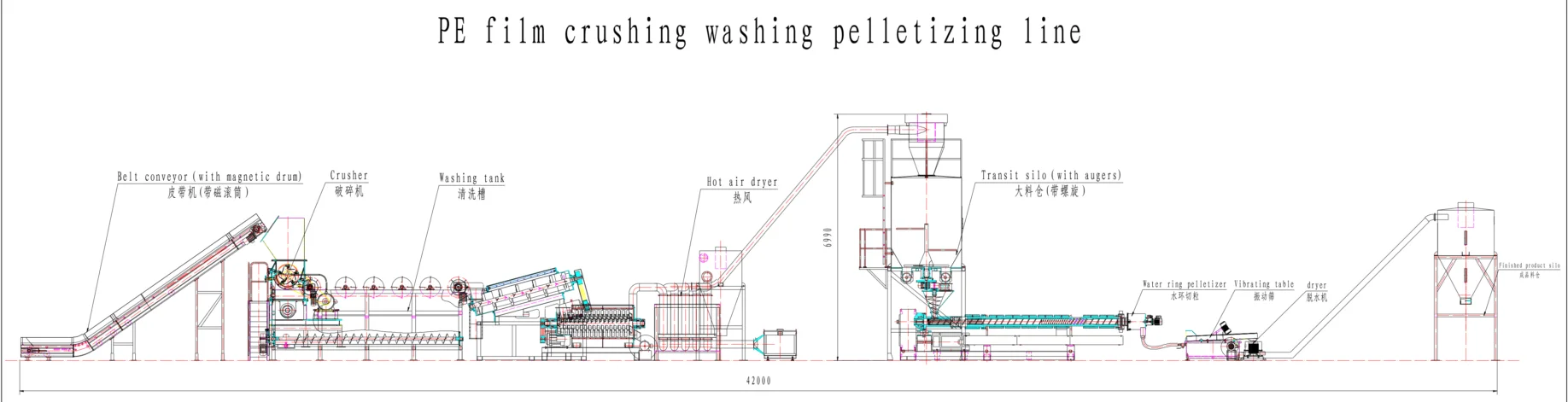

Process Flow Layout Example

A representative 500 kg/h layout showing each stage from bale opening and washing to drying and pelletizing.

Working Principle: A Step-by-Step Guide

The entire plastic film washing line is intelligently controlled via a central electric control panel and cabinet, ensuring synchronised operation. Each piece of equipment is seamlessly connected using conveyors for smooth material flow.

- 1. Plastic Shredder: The initial crucial step is to cut the film into smaller, manageable pieces (1–5 inches) to prevent tangling and blockages.

- 2. Plastic Granulator (Wet): Further reduces film size to 10–20 mm. Constant water injection serves as a pre‑treatment, partially cleaning the material.

- 3. Friction Washer: A high‑speed (≈1,000 RPM) unit that uses friction to dislodge stubborn contamination and break down paper into removable fibres.

- 4. Sink‑Float Separation Tank: Uses water to separate materials. PP/PE films float, while heavier contaminants like dirt, sand, and metals sink and are removed.

- 5. Centrifugal Dewatering: The first drying stage, using centrifugal force to remove a significant amount of water and save energy costs for thermal drying.

- 6. Screw Press Dewatering (Optional): An advanced option that squeezes water out via high pressure, potentially replacing both centrifugal and thermal drying stages.

- 7. Thermal Dryer: The film travels through stainless steel tubes with hot air to thoroughly dehydrate remaining moisture, ending in a cyclone separator to cool the film and remove fines.

- 8. Product Silo: A dedicated storage tank for the clean, dry pieces of plastic film before the final stage.

- 9. Plastic Pelletising Machine: The final, crucial step. A specialised water‑ring pelletising system processes the clean film into uniform, high‑quality plastic pellets.

Tip: Choose shredders when handling bulky bales and tough contaminants; opt for wet granulators when you want pre‑washing and tighter size control upfront.

Pre‑treatment: Shredder vs. Wet Granulator

Both approaches are effective. Your choice depends on feed form, contamination level, and downstream cleanliness targets.

-

Shredders Heavy‑duty, low‑speed tearing for bales and large films. Produces irregular pieces with low dust and noise — ideal as the first stage.

-

Crushers (Wet Granulators) High‑speed cutting that achieves tighter sizes and pre‑washing. Great for improving downstream washing efficiency early.

Drying Systems: Hitting Target Moisture

The goal before pelletising is consistently low moisture. Combine mechanical and thermal methods to reach stable output.

- Centrifugal Dewatering Rapidly removes surface water with low energy, preparing material for final drying.

- Screw Press (Optional) High‑pressure squeezing can replace centrifugal + thermal stages in some film applications.

- Thermal Drying Hot‑air tubes and cyclones bring moisture down to the level required for stable pelletising.

Main Technical Parameters

Specific technical parameters can vary based on the model and customisation. For detailed specifications, please refer to individual product sheets or contact us for a consultation.

| Input Capacity | 500kg/h | 1000kg/h | 1500kg/h | 2000kg/h | 3000kg/h |

|---|---|---|---|---|---|

| Required Space | 42m×15m×6m | 50m×15m×6m | 60m×25m×6m | 80m×30m×6m | 80m×40m×6m |

| Operators | 2-3people | 3-5people | 4-6people | 4-6people | 7-9people |

| Installation Power | 250kW | 350kW | 470kW | 650kW | 850kW |

| Water Circulation(T/H) | 2 | 3 | 3 | 4 | 5 |

Customising Your Film Washing Line

There is no one‑size‑fits‑all solution. The ideal configuration depends on your raw material, contamination level, and output goals. We gladly offer a complimentary solution‑design service to tailor the washing line to your needs.

Frequently Asked Questions

Our plastic film washing line is engineered to process a wide variety of materials, including but not limited to polypropylene (PP), polyethylene (PE), and other common plastic films. The system is designed to handle both loose and baled film.

The final output of our complete turnkey recycling line is high-quality, uniform plastic pellets. These pellets are clean, dry, and ready to be reintroduced into manufacturing processes to create new products.

Yes, absolutely. While our standard configurations range from 500kg/h to 3000kg/h, we specialize in providing custom-designed setups. We offer a complimentary solution design service to tailor a system with the specific machinery and capacity to meet your unique operational needs.

Long pieces of plastic film can easily tangle and clog conveyors and other rotary machines. The initial shredding step is crucial to cut the film into smaller, more manageable pieces, ensuring a smooth and efficient flow of material throughout the entire washing and pelletising line.

Inquiries & Project Scoping

Warranty: All recycling systems include a 1-year limited warranty and lifetime technical support.

Share your feedstock mix, contamination level, and throughput goals. We will prepare a tailored washing line configuration with timelines and budget.