Centrifugal Dryer & Dewatering Machine for Plastic Flakes

A high-speed centrifugal dryer (dewatering machine) that removes surface water from washed plastic flakes and film. It reduces energy load on thermal drying and helps keep washing lines stable for PE film, PET, HDPE and mixed rigid plastics.

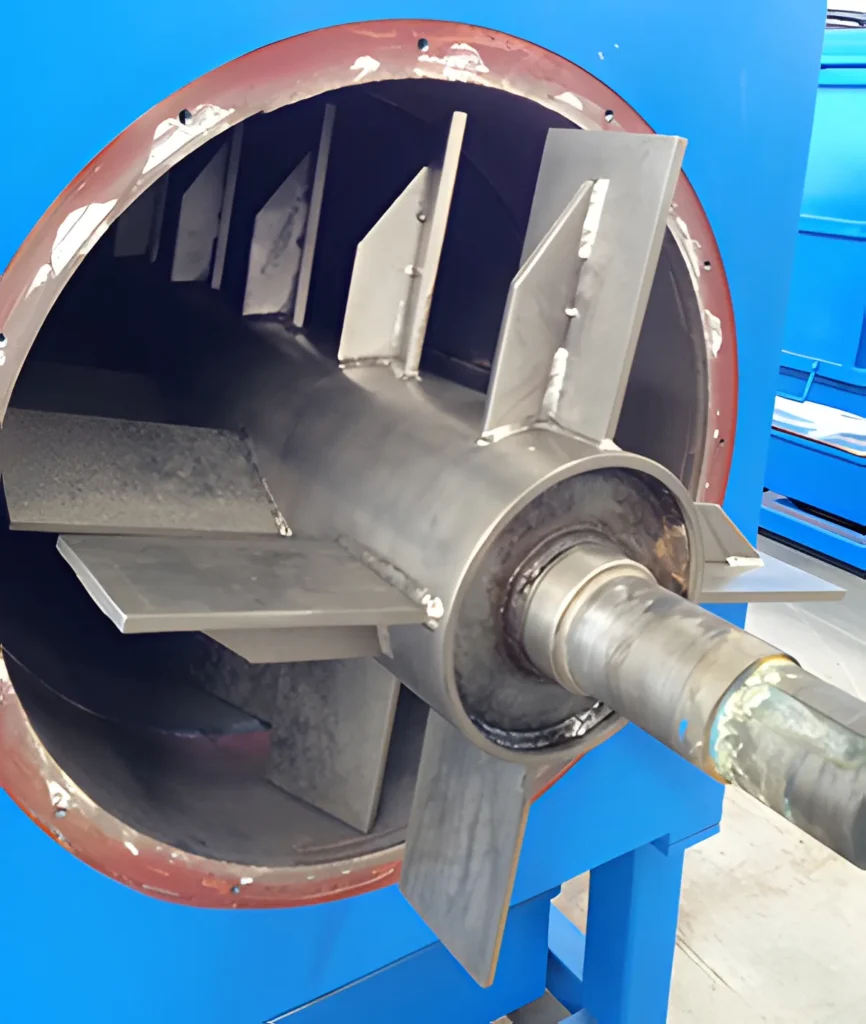

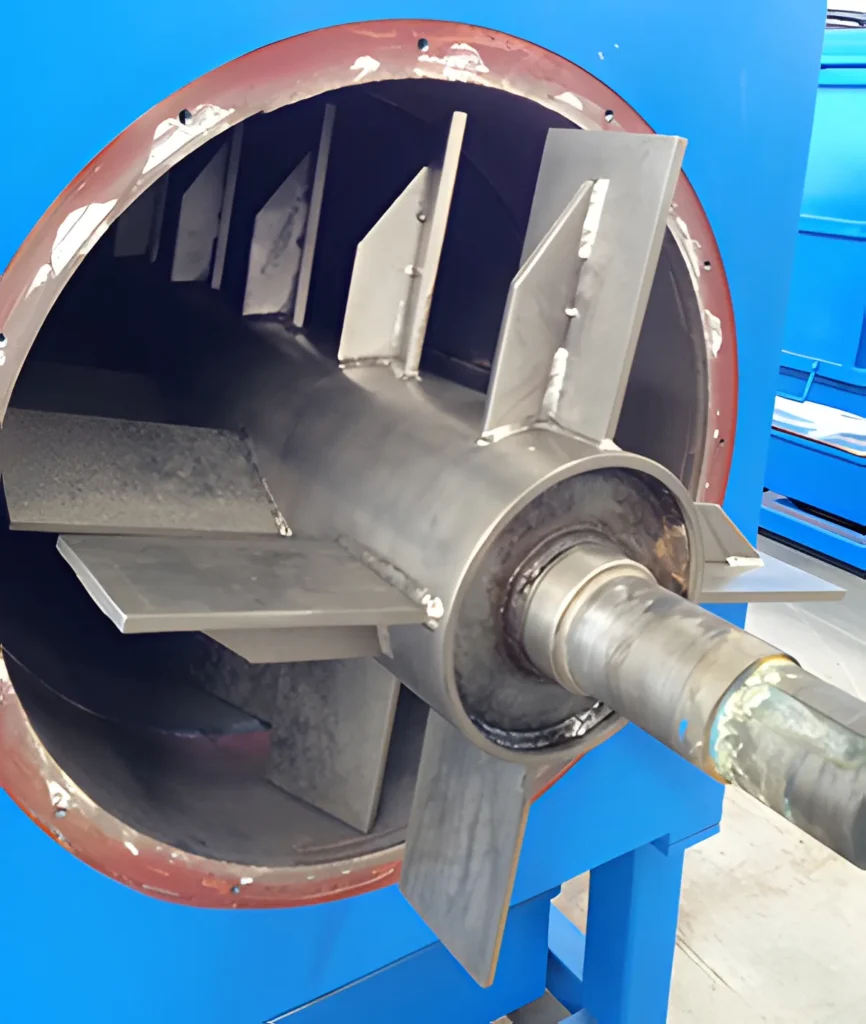

Working Principle

A rotor shaft with paddles spins at high speed inside a perforated screen tunnel. As washed flakes are fed in, centrifugal force throws water outward through the screen for collection while semi-dry plastic exits to the next stage—typically a hot air dryer or thermal drying system.

Key Advantages

Built for plastic recycling washing lines to dewater flakes efficiently and reduce thermal drying energy.

- Low Energy Consumption

As a mechanical drying process, it uses significantly less energy compared to thermal dryers, making it a highly cost-efficient first step.

- Dual-Function Cleaning

Our innovative design also functions as a friction washer, using cold water to cool and further scrub plastic flakes, improving final purity.

- High-Speed Efficiency

With rotation speeds up to 1400 RPM, it processes a high volume of material quickly, preventing bottlenecks in your washing line.

- Prepares for Final Drying

By removing the bulk of water, it makes the subsequent thermal drying stage faster and more effective, ensuring a high-quality end product.

Image Gallery

Technical Specifications

| Model | Motor Power | Main Shaft Diameter | Rotating Speed | Capacity |

|---|---|---|---|---|

| HXJ400 | 37KW | 400mm | 1400 RPM | 400 – 800 KG/H |

| HXJ550 | 45KW | 550mm | 1200 RPM | 600 – 1000 KG/H |

| HXJ750 | 55KW | 750mm | 1080 RPM | 1200 – 2000 KG/H |

Frequently Asked Questions

This machine serves as the crucial first step in the drying process. It uses centrifugal force to mechanically remove the majority of surface water from plastic flakes, which is a very energy-efficient method before the final thermal drying stage.

A dewatering machine can typically reduce the moisture content of washed plastic flakes down to approximately 20-30%. This prepares the material perfectly for a thermal dryer to achieve final moisture levels of under 3%.

Yes, our innovative design allows it to also function as a friction washer. It uses cold water to simultaneously cool and further scrub the plastic flakes, helping to remove any remaining fine contaminants.

It is designed for washed plastic flakes such as PET, HDPE, PP and rigid mixed flakes, and it can also be used for washed film flakes. The best configuration depends on flake size, density and incoming moisture level.

Selection depends on your washing line throughput, incoming moisture and flake characteristics. Choose a model whose capacity matches your line and leaves headroom to avoid bottlenecks; we can recommend HXJ400/550/750 based on your material and target output.

Request Pricing & Lead Time

To get the latest prices and lead times, send us a message using the form below.