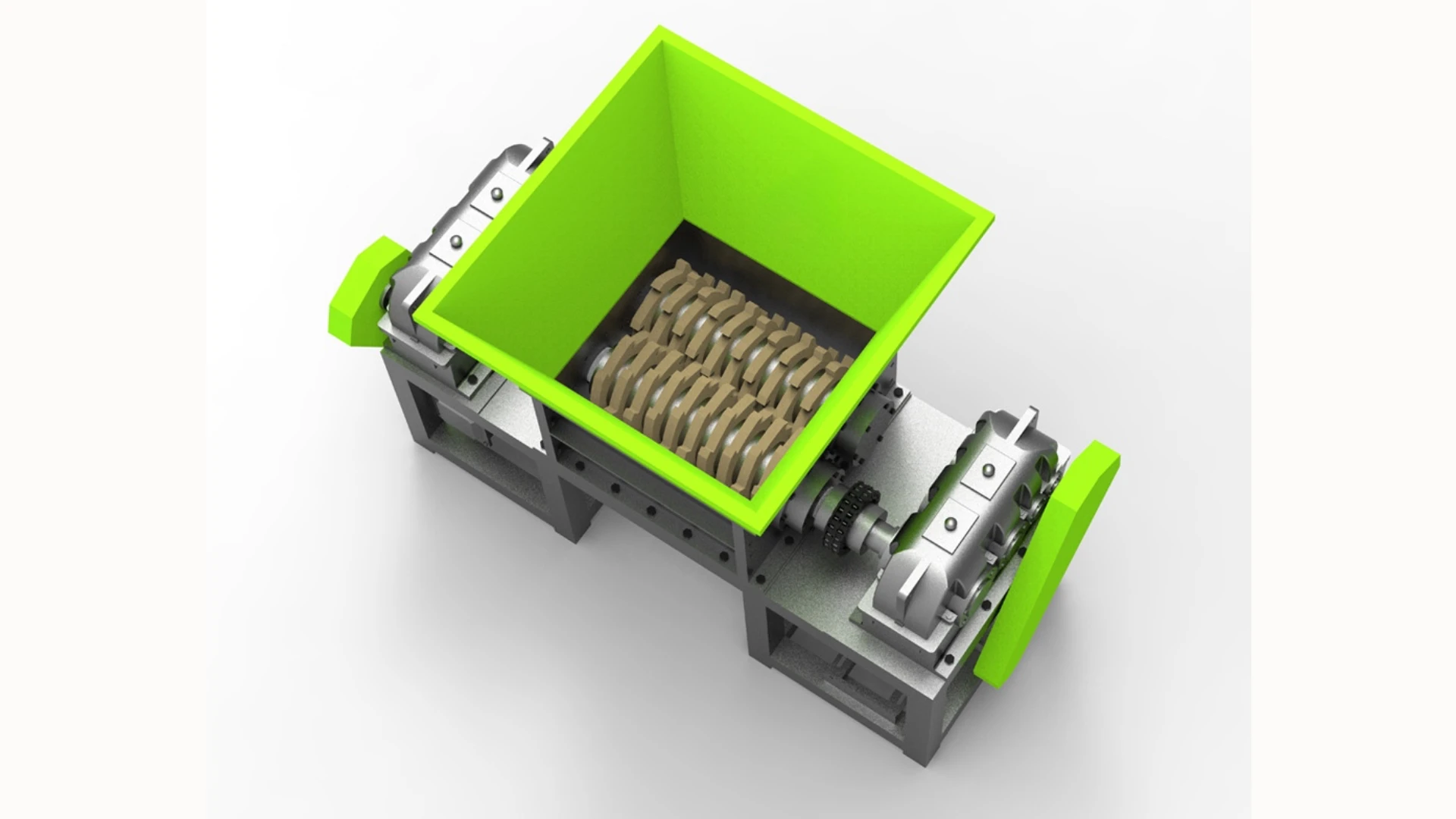

Effective Solutions for Pallet Recycling with Rumtoo Wood Grinders

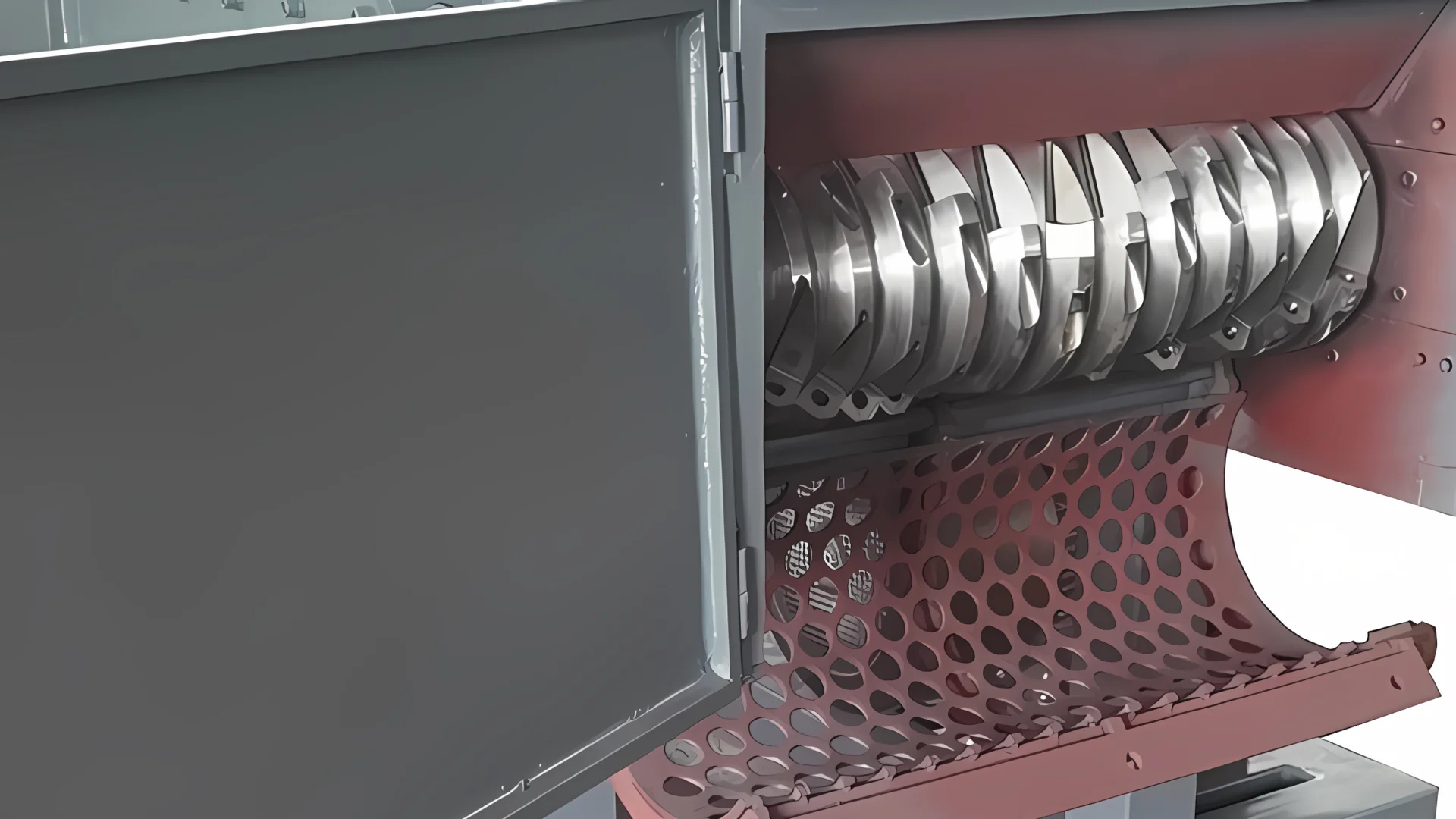

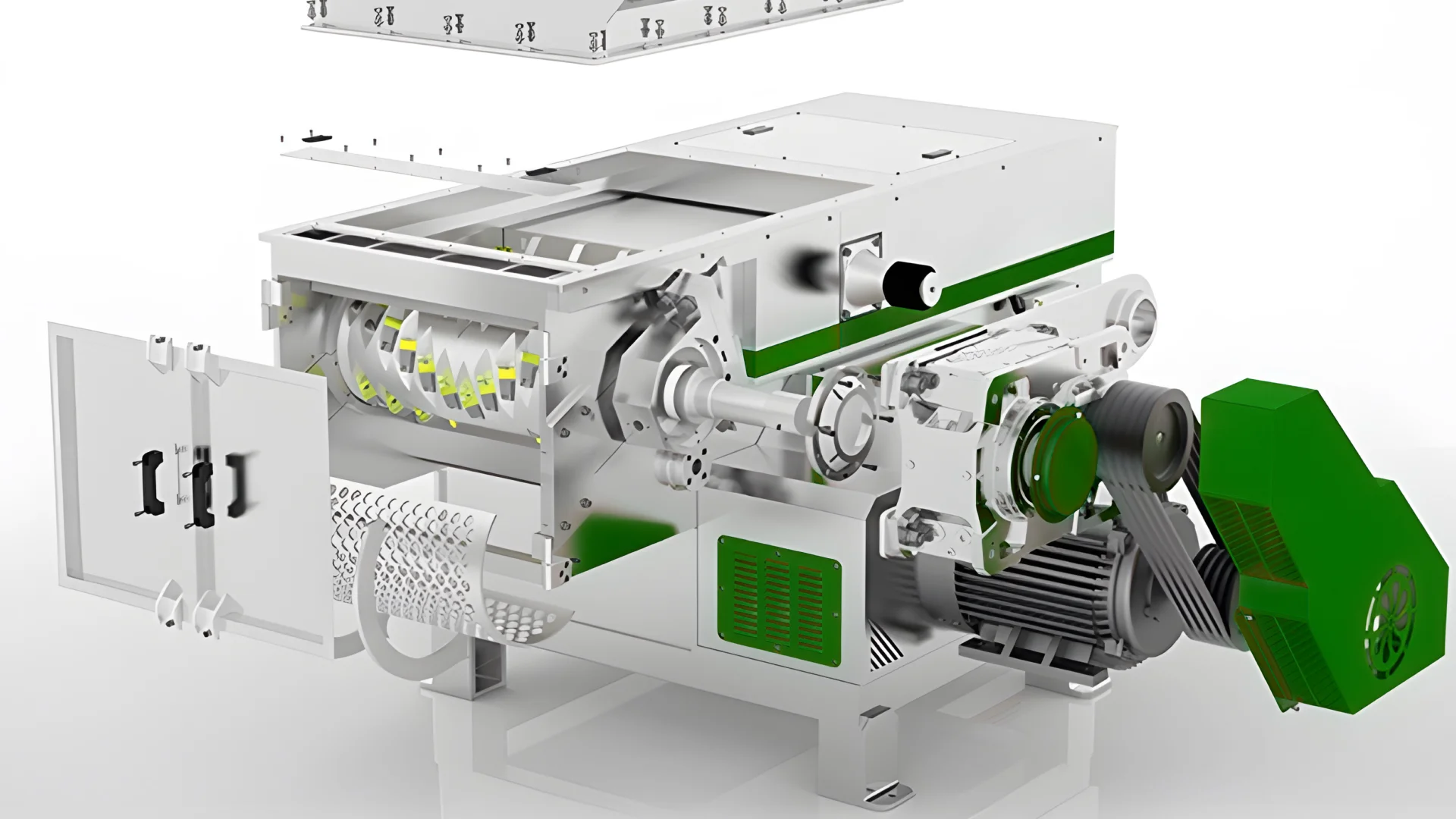

Reliable Equipment for Secondary Wood Processing Industries Industries involved in secondary wood processing, such as pallet, crate, and container manufacturing, as well as truss and structural building component production, an...