Efficient Separation with the Sink-Float Tank System

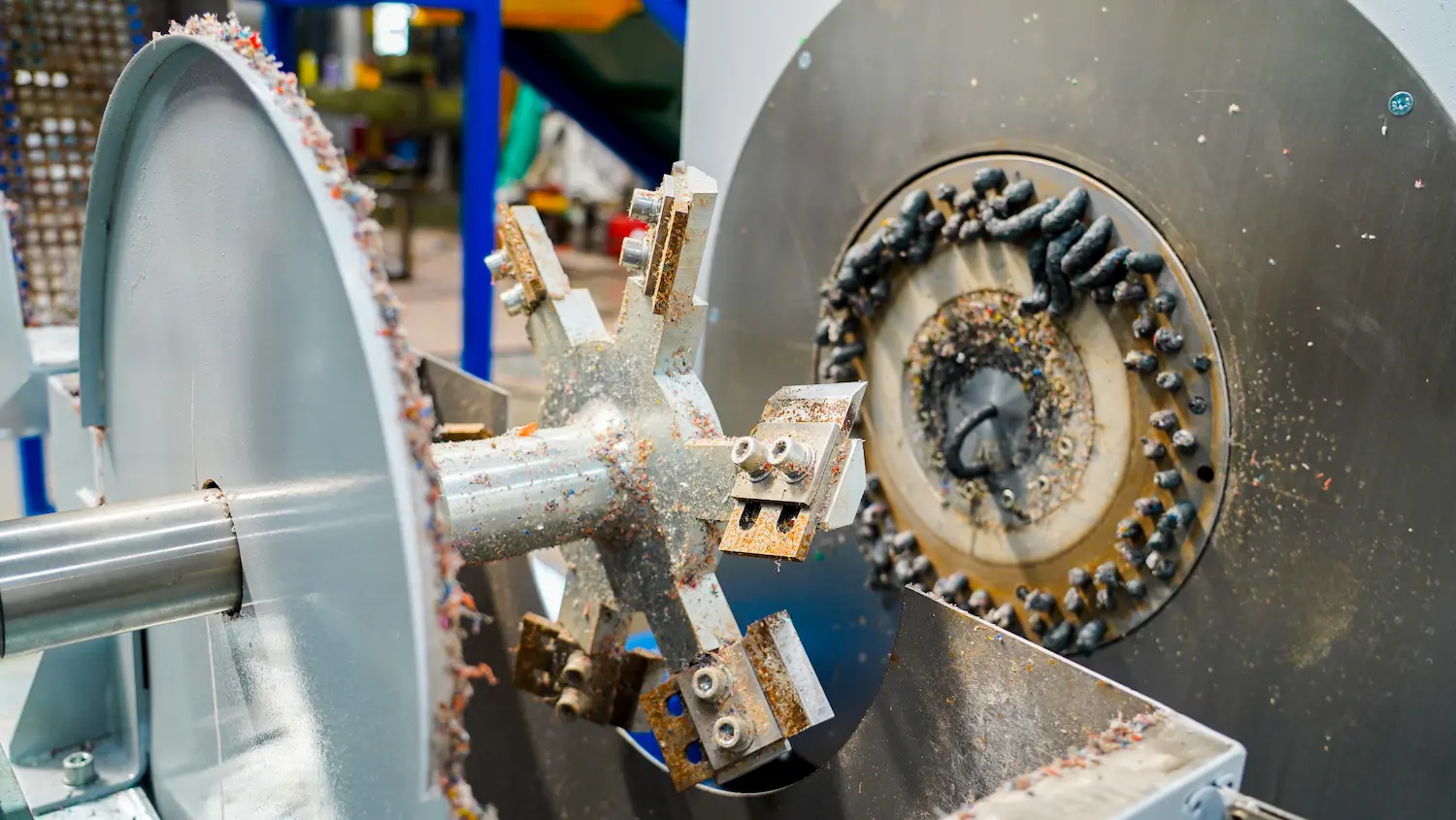

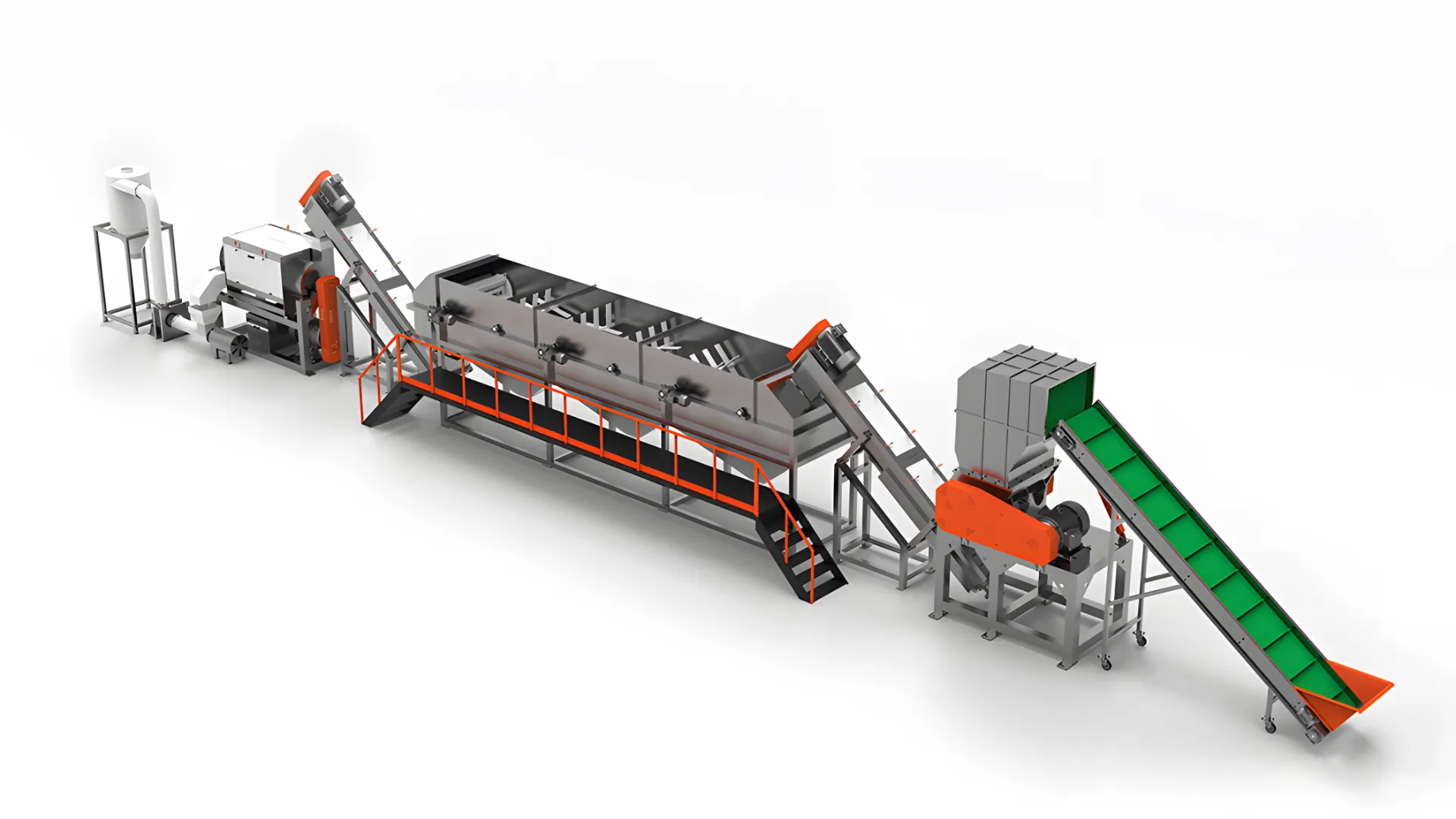

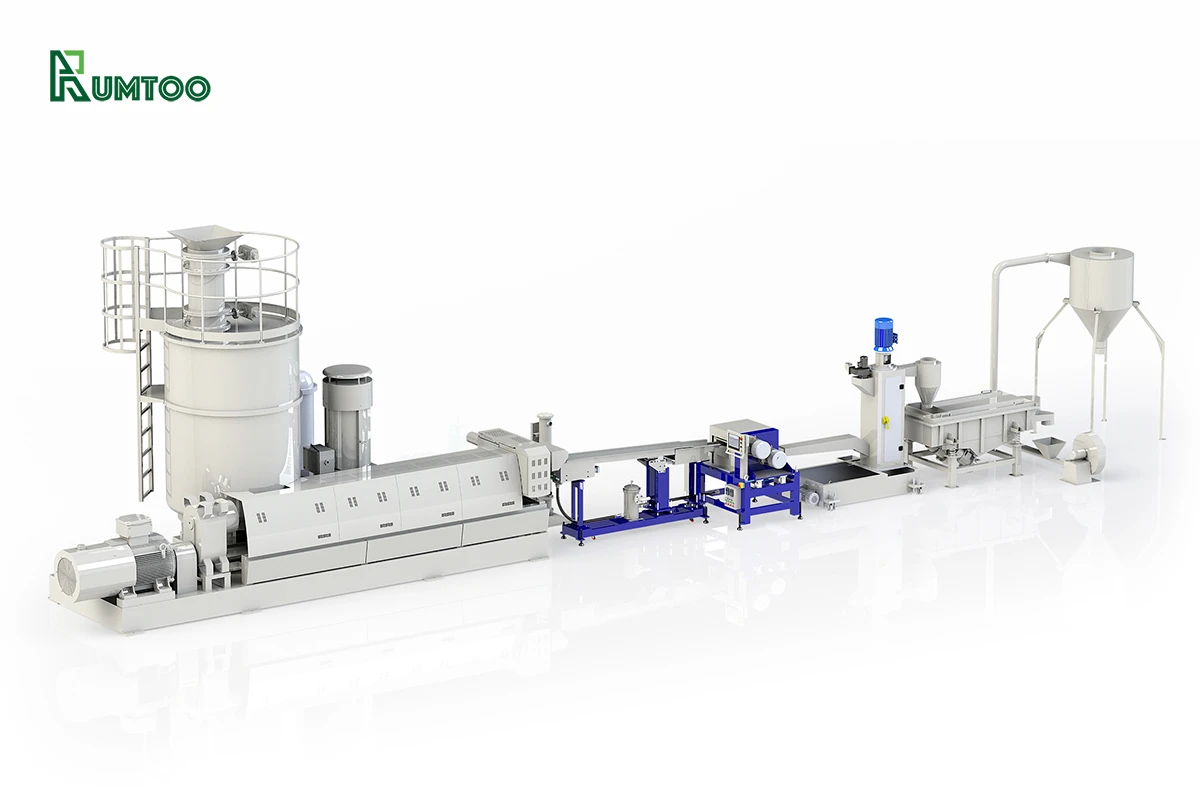

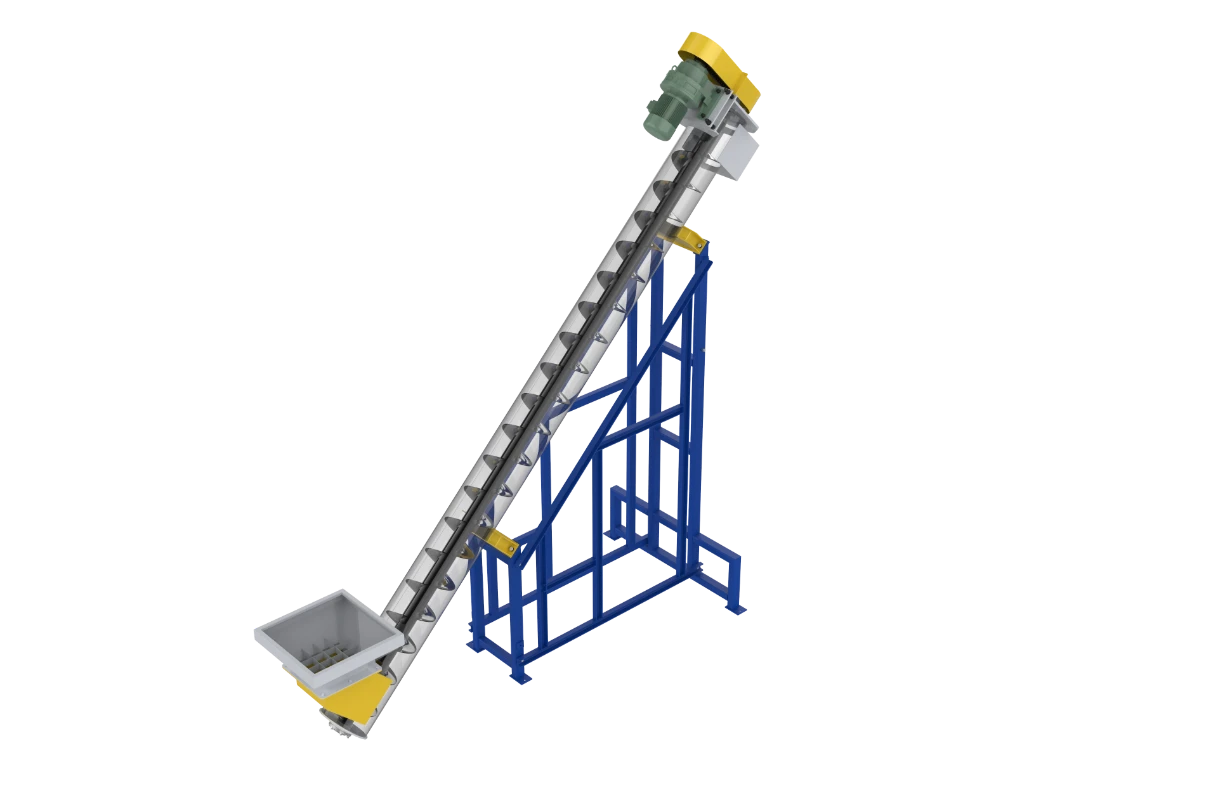

Introduction In the ever-evolving world of plastic recycling, the Sink-Float Tank System stands as a beacon of efficiency and effectiveness. This machine is a cornerstone in PET bottle recycling plants and other recycling appli...