Air separators play a crucial role in plastic recycling, particularly in removing lightweight contaminants like paper and cardboard from HDPE (High-Density Polyethylene) and PET (Polyethylene Terephthalate) bottles. These machines are an integral part of recycling lines, ensuring that the recycled plastic is free from impurities, thus improving the quality of the final product.

When it comes to maximizing the efficiency of recycling operations, particularly in removing non-ferrous metals from materials like post-consumer PET bottles, the advanced eddy current separator (ECS) stands out as a crucial piece of machinery. This sophisticated separator is not only vital in the plastic recycling industry but also plays an integral role in a variety of other sectors, ranging from glass and timber processing to the recycling of electronic scrap and automobile shredder residue.

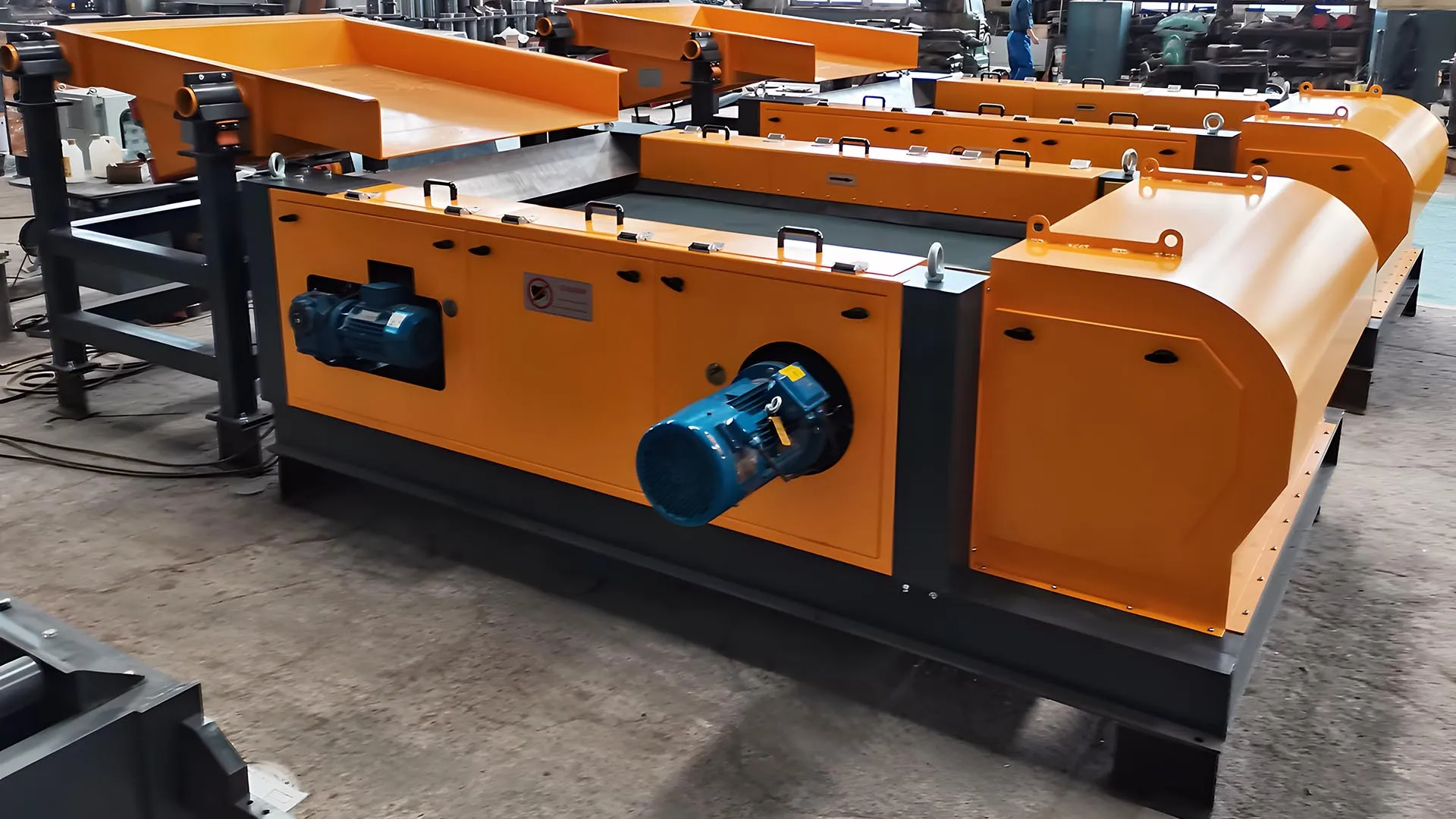

Plastic recycling is a dynamic industry that requires precision, efficiency, and the right equipment to ensure optimal results. One crucial tool that enhances the recycling process is the suspension magnetic separator. These machines are designed to recover valuable ferrous metals and remove harmful tramp ferrous metals, thereby protecting downstream equipment and improving the quality of recycled products.

When it comes to plastic recycling, separating contaminants from valuable materials is critical for ensuring a high-quality end product. This is where trommel machines come into play. These slow-rotating, cylindrical separation machines are essential in plastic recycling plants and larger Material Recovery Facilities (MRFs) dealing with municipal waste. Despite their leisurely pace, trommels are incredibly effective at filtering out smaller contaminants from recycling streams, making them a key component in the recycling process.

In the world of plastic recycling, separating different types of plastics efficiently and effectively is crucial. The PP PE plastic floating separation tank is one of the most essential tools in this process. This tank uses water as a medium to segregate polypropylene (PP) and polyethylene (PE) from mixed plastic streams, utilizing their distinct densities. Not only does it ensure accurate separation, but it also cleans the materials, preparing them for further processing. Let's delve deeper into how this ingenious system works and why it's a cornerstone of modern plastic recycling.

Our Disk Separator is a highly efficient machine designed to separate material streams based on size. Whether you're dealing with plastics, paper, metals, or other mixed materials, this machine ensures precise separation tailored to your needs. Its customizable features and robust construction make it a top choice for various industrial applications.

Our eddy current separators are crucial pieces of machinery for separating aluminum and other non-ferrous metals from various process streams. Since non-ferrous metals typically hold higher value, recovering this stream is a vital aspect of numerous recycling facilities across the globe.

Our wet plastic bottle label remover is an innovative recycling machine capable of removing more than 95% of the labels from intact plastic bottles. As this machine utilizes water to detach the labels, the bottles are cleaned simultaneously, making this an excellent option to enhance your current or new PET bottle recycling operation.

In the world of plastic recycling, efficiency and cleanliness are paramount. Whether you're running a large-scale recycling operation or a smaller setup, the key to producing high-quality recycled plastic is ensuring that contaminants are effectively removed. Enter the high-speed friction washer—a machine specifically designed to elevate your recycling process by delivering cleaner, more refined plastic with less water waste. This article delves into the inner workings, benefits, and technical specifications of this essential piece of machinery.

The Triple-Row Sink Float Separation Tank represents a groundbreaking advancement in plastic separation technology. This innovative system has been completely re-engineered to provide the efficiency of three traditional-style floating tanks combined into one robust unit. With this new design, industries can achieve superior plastic separation, especially when dealing with highly contaminated materials.