Top Plastic Recycling Machines for Efficient Waste Management

Recycle and reuse mechanical products, protect the environment and save resources.

Learn about the recycling process, methods, equipment and more.

Vertical Mixing Dryer Overview

A vertical mixing dryer, also known as a lifting stirring dryer or a granular blending machine, utilizes rotating mixing blades to agitate plastic raw materials, achieving rapid mixing of granular materials. It is primarily designed for blending and coloring various plastic granules, making it an essential auxiliary device for extruders, injection molding machines, and granulating machines. The base of the plastic mixing and coloring machine can be equipped with casters for easy mobility. This equipment features a sealed mixing process that is secure and dependable, achieving uniform mixing in a short period. Additionally, it is equipped with a timer to freely adjust the mixing duration. The machine is characterized by even mixing, a compact structure, an attractive appearance, easy assembly and disassembly, and straightforward cleaning.

Primary Functions of the Vertical Mixing Dryer

The vertical mixing dryer is mainly used for mixing different colored plastic granules. The equipment has two primary functions: hot air drying of plastic granules and uniform blending of plastic granules with functional masterbatches and fillers. The machine employs rotating mixing blades to stir and agitate plastic materials, facilitating rapid mixing. It is one of the auxiliary devices for injection molding machines and granulating machines.

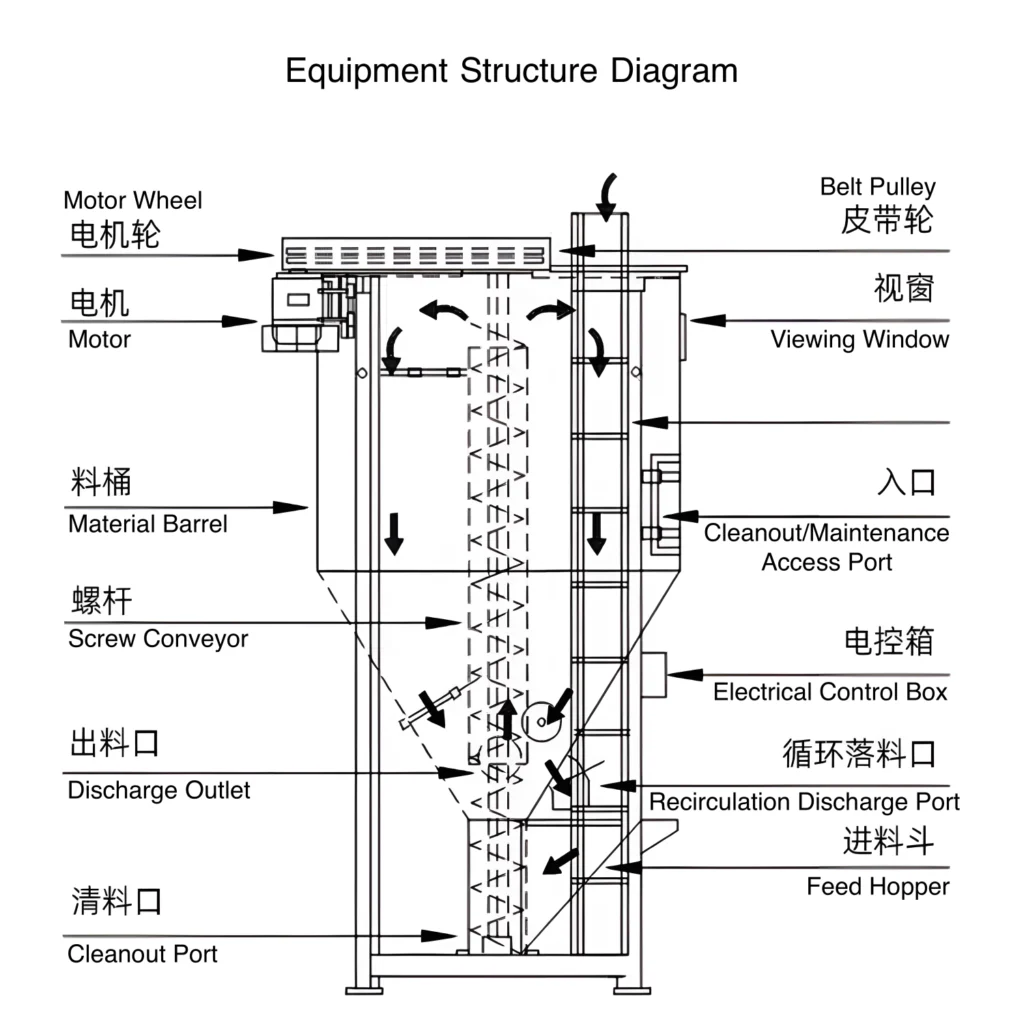

Working Principle of the Vertical Mixing Dryer

Plastic granules enter from the feed hopper and, under the pushing force of the spiral blades, slide upward along the blade surface to the top. There, centrifugal force causes them to spread out in an umbrella shape around the barrel, continuously moving downward. The material falling from the top into the bottom of the mixer is automatically fed into the vertical screw conveyor, where it is lifted and mixed again. This cycle repeats until thorough mixing is achieved. Simultaneously, air is delivered by a blower into the electric heating box, where it is heated and then automatically controlled by a temperature controller. This evenly heated air penetrates through the resin layers, exchanging heat and continuously removing moisture. The resin granules are continuously dried as they descend from top to bottom, completing the drying and mixing process.

Features of the Vertical Mixing Dryer

The mixing blades and barrel of the vertical mixing dryer are made of stainless steel, making them easy to assemble, disassemble, and clean. The barrel includes an insulating layer in the middle to reduce heat loss during the drying process, thus improving drying efficiency. The optional heating function uses stainless steel heating rods to dry plastic granules with hot air. Temperature points are set in the hot air duct and barrel, and heating temperature and time are automatically controlled by a PID intelligent temperature controller. The mixing power is delivered by a stainless steel screw-lift drying method, featuring low noise, low power requirements, and uniform mixing. The base of the barrel is made of steel, capable of supporting a large weight of plastic materials. An observation window on the barrel allows operators to monitor the drying and mixing process clearly. The low feed port design significantly reduces the labor intensity and difficulty for operators, improving production efficiency. A time relay controls the heating and mixing duration, while a centrifugal fan provides a large volume of hot air, reducing energy loss in the heating section and significantly improving the heating effect.

Vertical Mixing Dryer Product Characteristics:

- Safety Protection: Equipped with an electronic safety protection device to ensure safe operation.

- Stainless Steel Construction: The entire unit is made of stainless steel, resistant to acids, alkalis, and corrosion, with a small footprint, reasonable design, and durable, aesthetically pleasing appearance.

- Dual-layer Barrel Design: (The economical version has a single-layer design.) The inner layer, which contacts the material, is made of stainless steel, with a special insulation material installed in the middle layer.

- Stainless Steel Blades: Scientifically and reasonably designed for optimal raw material mixing with low load, time-saving, and energy-efficient. The stainless steel construction with polished treatment ensures high gloss and easy cleaning.

- Detachable Blades: The blades are detachable, and the mixing chamber is made of stainless steel, making it easy to clean.

- Direct Motor Drive: High mixing efficiency.

- Vertical Design: Takes up minimal space and allows for easy unloading.

- Timer Control: Allows the selection of mixing time between 0-30 minutes.

- Multiple Safety Protections: Ensures the safety of the operator.

- Four-wheel Vertical Design: Compact, mobile, and easy to maneuver.

- Cycloidal Pinwheel Reducer Motor: Low noise, durable.

- Quick and Uniform Mixing: Achieves uniform mixing in a short time with low energy consumption and high efficiency.

- Durable Construction: The barrel cover and base are formed through stamping, making them more durable.

- Simultaneous Mixing and Drying: As the material remains in motion during the drying process, it dries uniformly, with short drying times and minimal clumping.

- Stainless Steel Barrel and Blades: The barrel and mixing components are made of stainless steel.

- Convenient Discharge: The discharge port has a manual valve for easy unloading.

- Safety Interlock: Ensures the safety of the operator.

Vertical Mixing Dryer Maintenance and Operation Guidelines

Inspection Checklist:

- Check for loose mixing blades and ensure proper lubrication.

- Connect the power supply correctly, open the lid, and check for foreign objects in the barrel.

- Ensure the power supply voltage matches the nameplate.

- Perform a no-load test run to check for normal operation and verify the mixing blade rotation direction before starting production.

- Inspect rotating parts for flexibility and remove any foreign objects blocking the main shaft in the barrel.

Operation Instructions:

- Install the machine independently, and secure it with anchor bolts if necessary.

- Pay close attention to the motor's rotation direction when connecting the three-phase power supply.

- After starting the machine, allow it to run for 2-5 minutes without load to confirm normal operation before feeding materials.

- For mixing and coloring, set the time on the timer, adjust the temperature on the temperature controller, and start the machine. It will stop automatically when the material reaches the set temperature, and can be restarted if necessary.

- For drying, set the required temperature on the temperature controller, and adjust the time for the drying cycle. The machine will stop once the material is adequately dried.

- To stop the machine, switch to the stop mode or press the OFF button.

Maintenance and Care:

- Always disconnect the main power before performing maintenance or repairs.

- Lubricate the bearings with ZL-2 lithium-based grease weekly.

- Clean the parts in contact with materials with white mineral oil or diesel before changing colors.

- If there is an electrical protection fault, have a technician inspect, repair, and resolve the issue before restarting the machine.

In the plastic recycling industry, effective drying processes are crucial to ensure high-quality output and efficient operations. A Pipe Drying System specifically designed for plastic recycling can significantly improve the drying process, reducing moisture content and enhancing the overall quality of the recycled material. This article explores the key features, benefits, and applications of a Pipe Drying System tailored for plastic recycling.

This video provides a comprehensive look at the PE film recycling washing line process and its benefits.

The video opens with footage of discarded PE film waste, emphasizing the importance of recycling. We then take you on a tour of an advanced PE film recycling washing line, showcasing the following key processes:

Welcome to our detailed introduction of the Waste Plastic Film Pelletizing Machine, a cutting-edge solution designed for efficient recycling and pelletization of plastic films, woven bags, and other soft materials. This advanced machine is equipped with several key features that enhance performance, durability, and ease of operation.

Introduce

In this video, we take you through the comprehensive process of washing PP PE rigid regrinds, showcasing the efficiency and effectiveness of the entire system. The video begins with the High-Speed Friction Washer, where intense friction removes contaminants and prepares the material for further cleaning. Next, we demonstrate the Sink-Float Separation stage, a critical step that separates heavier contaminants from the plastic using differences in density.

A single-shaft shredder is an essential piece of equipment designed to efficiently handle the shredding of extruder head waste. This machine is built with a robust structure that includes a motor, a reducer with rigid gears, a rotary shaft, imported rotary knives, fixed knives, a sturdy frame, a working platform, a hydraulic ram, and an independent electrical control cabinet.

Comprehensive Plastic Recycling Equipment List with Detailed Specifications

This detailed list outlines the essential machinery and equipment used in a high-efficiency plastic recycling production line. The list includes specifications for belt conveyors, granulators, screw conveyors, separators, washing tanks, thermal dryers, de-watering machines, and more. With a total installed power of 310KW and a production capacity of 1,000 to 1,500 KG/h, this equipment setup is designed for optimal performance in plastic recycling processes. Perfect for businesses aiming to enhance their recycling operations.

Recycling post-consumer plastics like PE film, PP woven bags, and agricultural films can be a challenge due to high moisture content. Washed films typically contain up to 40% moisture, which is problematic for recyclers, leading to issues like inconsistent feeding and reduced output in recycling extruders. Traditional drying methods often fail to effectively remove this moisture, leaving up to 30% water content in the materials.

In the world of plastic recycling, separating different types of plastics efficiently and effectively is crucial. The PP PE plastic floating separation tank is one of the most essential tools in this process. This tank uses water as a medium to segregate polypropylene (PP) and polyethylene (PE) from mixed plastic streams, utilizing their distinct densities. Not only does it ensure accurate separation, but it also cleans the materials, preparing them for further processing. Let's delve deeper into how this ingenious system works and why it's a cornerstone of modern plastic recycling.

Air separators play a crucial role in plastic recycling, particularly in removing lightweight contaminants like paper and cardboard from HDPE (High-Density Polyethylene) and PET (Polyethylene Terephthalate) bottles. These machines are an integral part of recycling lines, ensuring that the recycled plastic is free from impurities, thus improving the quality of the final product.

When it comes to plastic recycling, separating contaminants from valuable materials is critical for ensuring a high-quality end product. This is where trommel machines come into play. These slow-rotating, cylindrical separation machines are essential in plastic recycling plants and larger Material Recovery Facilities (MRFs) dealing with municipal waste. Despite their leisurely pace, trommels are incredibly effective at filtering out smaller contaminants from recycling streams, making them a key component in the recycling process.

Our Disk Separator is a highly efficient machine designed to separate material streams based on size. Whether you're dealing with plastics, paper, metals, or other mixed materials, this machine ensures precise separation tailored to your needs. Its customizable features and robust construction make it a top choice for various industrial applications.