Contents

Introduction:

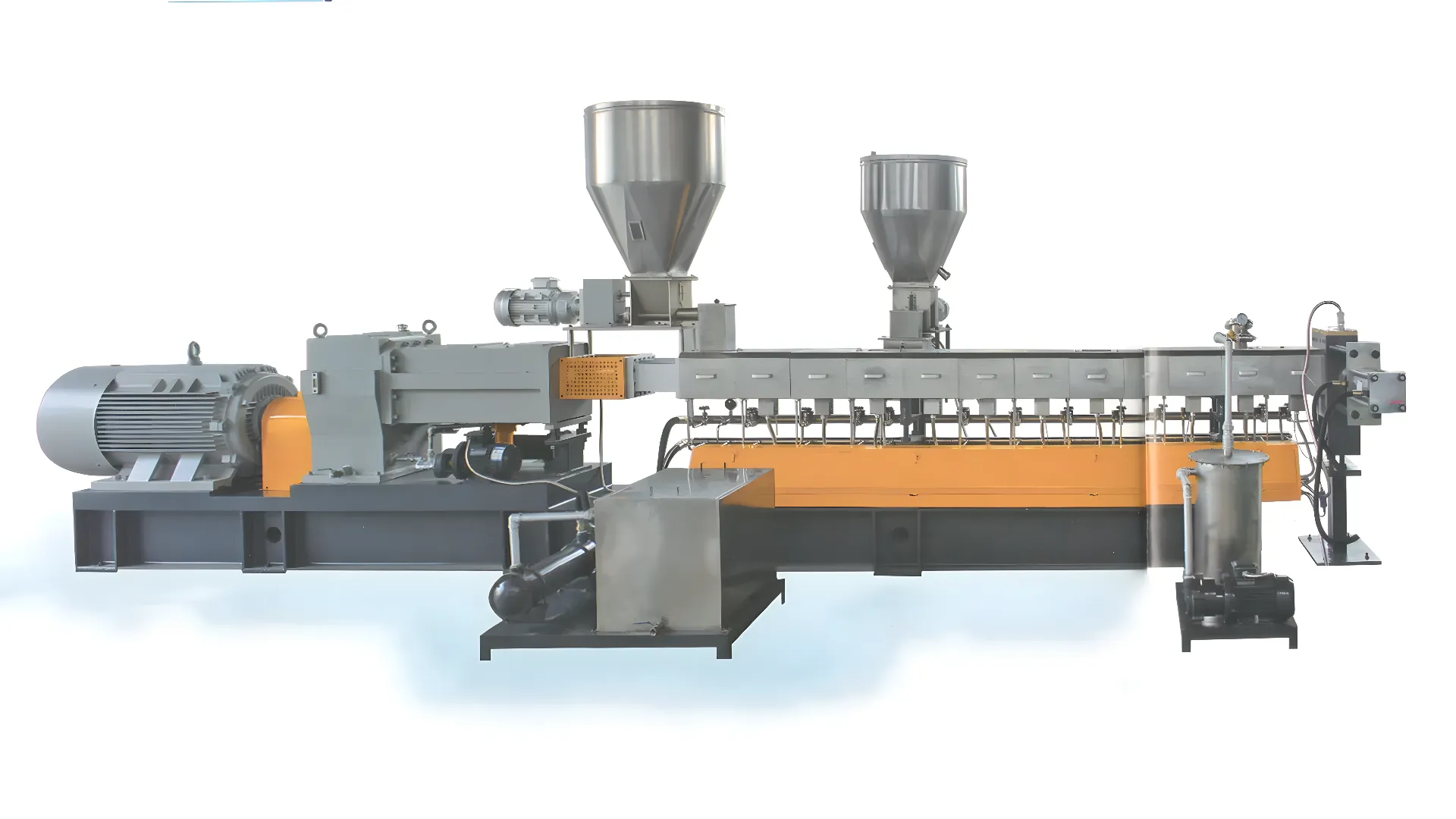

The Twin Screw Compounding Pelletizing Line is a state-of-the-art solution for polymer processing, offering unparalleled versatility and adaptability to meet the diverse needs of the industry.

Principles and Features:

Our pelletizing line is designed with a modular concept, allowing for customization in screw configuration, barrel structure, length-to-diameter ratio, feeding and venting positions, screen changing and pellet cutting methods, and electrical and control automation modes. This flexibility ensures a balance between multi-functionality and the ability to meet specific requirements.

Key Features:

- Motor Speed Control: Utilizing renowned digital frequency converters or DC speed controllers for reliable and top-tier performance.

- Temperature Control: Equipped with RKC or OMRON digital intelligent temperature controllers or integrated control modules for high precision and PID parameter optimization.

- Cooling System Components: High-quality solenoid valves from international brands ensure long-term reliability.

- Low Voltage Electrical Components: Internationally recognized brands such as Schneider, Siemens, and Fuji are used for electrical control cabinets designed for easy maintenance and ventilation.

Screw Elements:

The basic screw elements are designed with a fully interlocking conjugate type, offering excellent self-cleaning properties and interchangeability. Leveraging two decades of experience in screw design and software technology, our line can efficiently perform various functions such as conveying, melting, mixing, shearing, homogenizing, devolatilization, and extrusion.

Series and Customization:

We offer a range of series including the standard A series, high-speed B series, high-torque C series, high-speed and high-torque D series, and the newly launched E and F series with even higher torque capabilities, providing a wide selection for various user needs.

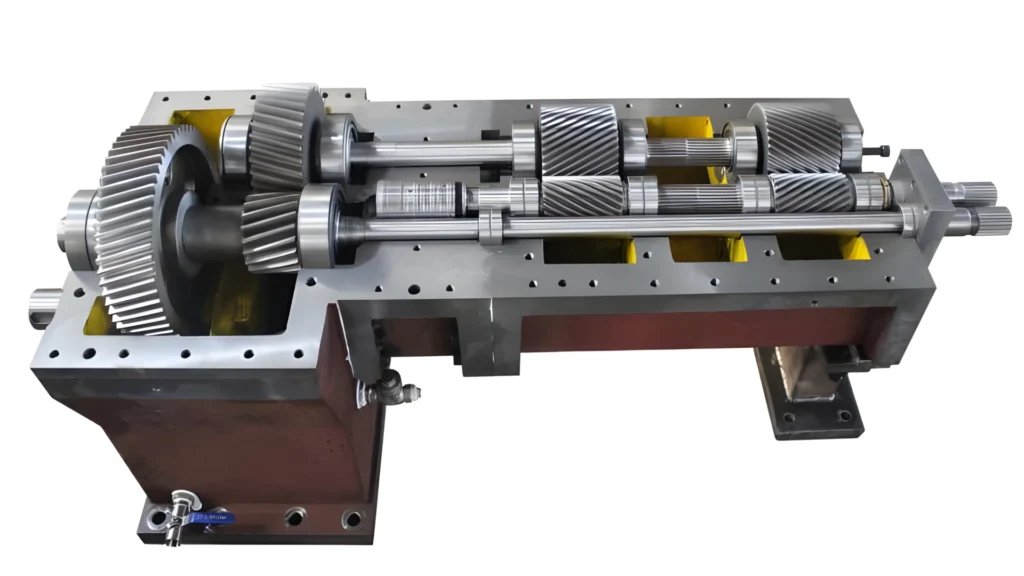

Transmission Device:

Our new torque distribution transmission device is designed with a focus on safety margin, precision, and reliability, featuring high-precision gear machining and fully imported key bearings.

Feeding Systems:

Multiple types of metering feeding structures and systems are available, including single-screw, twin-screw, hollow spring types, and both meshing and non-meshing options, accommodating various material states and processes.

Materials and Construction:

The standard barrel material is bi-metallic, with a 45# steel base and an 8101 alloy liner, offering high wear resistance suitable for most operations. Special materials and treatments are available for corrosive or abrasive applications.

Ease of Use:

The machine operates with low vibration and noise, allowing for foundationless installation on a flat surface, reducing site and installation requirements for greater convenience.

Specifications

| Model | Diameter (mm) | Max. L/D Ratio | Speed (RPM) | Power (kW) | Output (kg/hour) |

|---|---|---|---|---|---|

| RTM52C | 51.4 | 68 | 600 | 90 | 250~350 |

| RTM65C | 62.4 | 68 | 600 | 160 | 400~600 |

| RTM75C | 71.4 | 68 | 600 | 250 | 700~1000 |

| RTM85C | 81 | 68 | 600 | 280 | 800~1200 |

| RTM95C | 93 | 68 | 600 | 450 | 1300~2000 |

| RTM120C | 116 | 68 | 500 | 550 | 1500~2200 |

| RTM135C | 133 | 68 | 500 | 1200 | 3500~5000 |

Conclusion:

Our Twin Screw Compounding Pelletizing Line represents the pinnacle of polymer processing technology, combining adaptability, precision, and user-friendliness to meet the evolving demands of the industry.