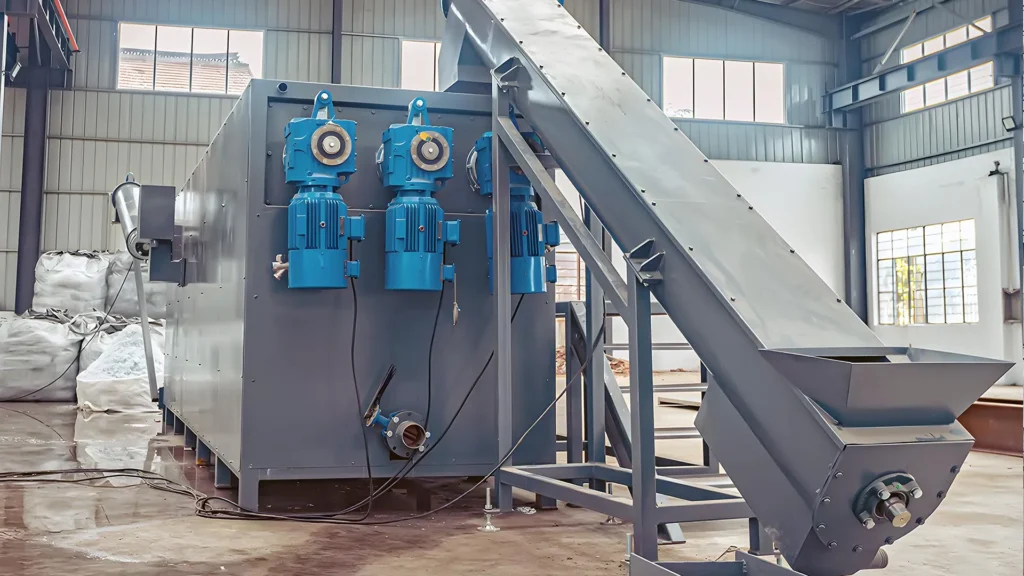

The Triple-Row Sink Float Separation Tank represents a groundbreaking advancement in plastic separation technology. This innovative system has been completely re-engineered to provide the efficiency of three traditional-style floating tanks combined into one robust unit. With this new design, industries can achieve superior plastic separation, especially when dealing with highly contaminated materials.

Contents

Working Principle

The working mechanism of the Triple-Row Sink Float Separation Tank is both innovative and efficient. A large, powerful motor drives three top screws, which continuously push the plastic material forward along the length of the tank. Under these screws, a mesh screen is strategically placed to filter out small contaminants, ensuring that only the plastic materials move forward for separation.

The key to the tank’s efficiency lies in its unique design. Unlike traditional tanks where the dirty plastic stream travels down the tank only once, this advanced model is split into three distinct rows. This design allows the material to travel three times the distance, providing ample time for the plastic to soak, separate, and clean thoroughly. The extended washing period is crucial for removing stubborn contaminants, resulting in a higher purity of separated plastic.

Advantages of the Triple-Row Design

- Enhanced Separation Efficiency: The extended travel distance through three rows allows for more thorough soaking and separation, improving the overall efficiency of the process.

- Superior Contaminant Removal: The longer washing time ensures that even highly contaminated plastics can be effectively cleaned and separated.

- Optimized Design: The triple-row configuration means that the same footprint as traditional tanks now offers triple the separation power, maximizing space and resource efficiency.

- Cost-Effective Solution: With improved efficiency and higher throughput, the Triple-Row Sink Float Separation Tank reduces operational costs over time.

Practical Applications and Customer Feedback

The Triple-Row Sink Float Separation Tank is particularly effective in industries dealing with post-consumer plastics or materials with a high level of contamination. Customers who have tested this equipment report significant improvements in the cleanliness and separation of their plastic streams. This machine is becoming a vital component in modern recycling facilities where high efficiency and purity levels are critical.

Conclusion

Incorporating the Triple-Row Sink Float Separation Tank into your plastic separation process is a smart investment that promises enhanced efficiency, superior contaminant removal, and long-term cost savings. By tripling the separation power within the same space, this tank is poised to set new standards in the plastic recycling industry.

Additional Images

Warranty & Installation

Each recycling machine includes a 1-year limited warranty. We provide installation services, with our engineers visiting your site to assist with the setup process. Arrangements for regular maintenance crews and operational consultants can also be made.

Inquire Now

To get the latest prices and lead times, send us a message using the form below.