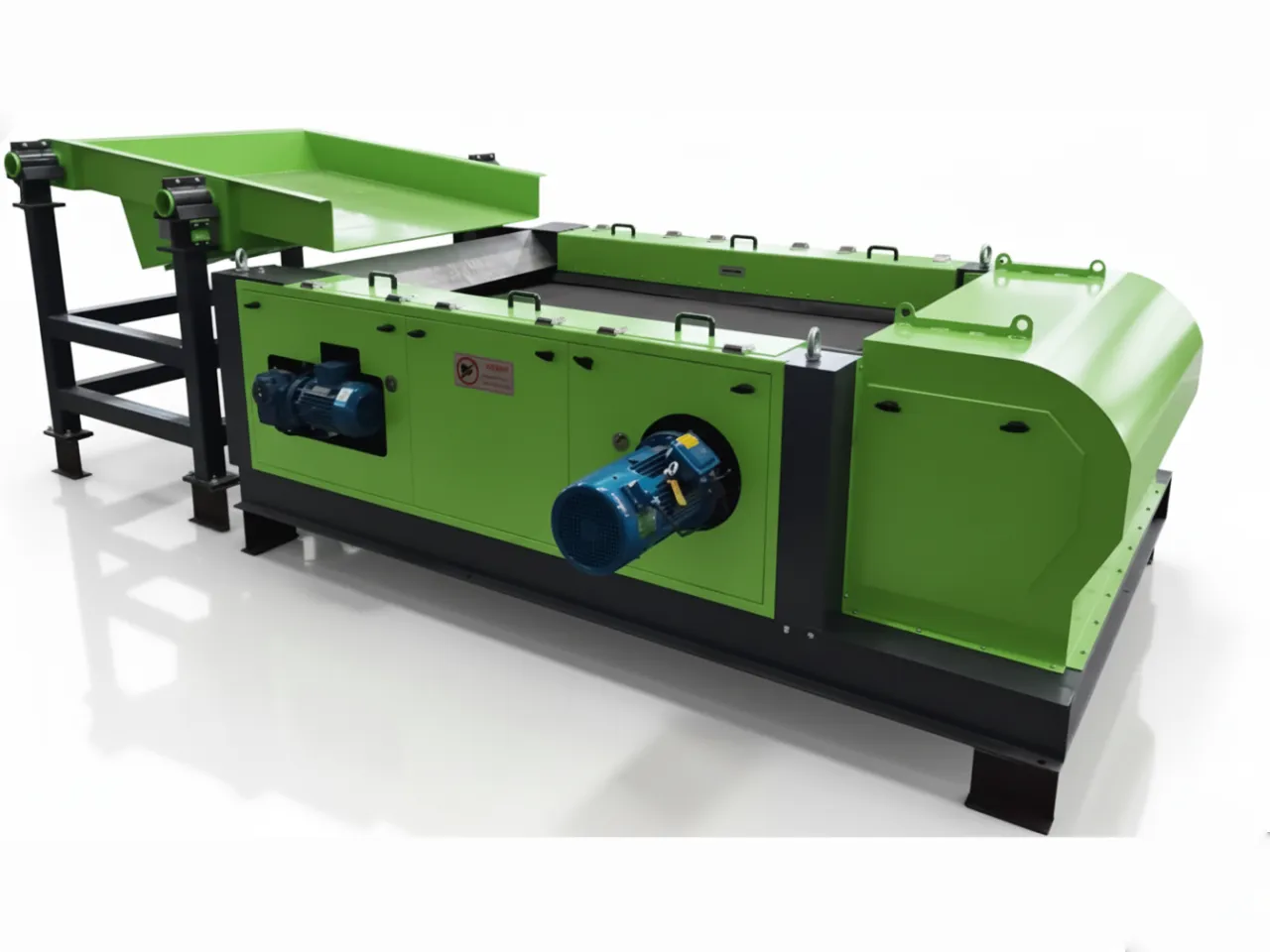

When it comes to maximizing the efficiency of recycling operations, particularly in removing non-ferrous metals from materials like post-consumer PET bottles, the advanced eddy current separator (ECS) stands out as a crucial piece of machinery. This sophisticated separator is not only vital in the plastic recycling industry but also plays an integral role in a variety of other sectors, ranging from glass and timber processing to the recycling of electronic scrap and automobile shredder residue.

What is an Advanced Eddy Current Separator?

At its core, an advanced eddy current separator is a machine designed to remove non-ferrous metals from recycled material streams. These non-ferrous metals include aluminum, brass, bronze, and copper—materials that are not only valuable but also need to be separated from the rest of the recycled material to improve the purity and marketability of the final product.

In particular, the use of these separators in PET bottle recycling is revolutionary. They effectively remove high-value metals, which can otherwise contaminate the recycled PET, lowering its quality and value. By ensuring these metals are extracted, the advanced ECS helps produce a more valuable end product, contributing to both economic efficiency and environmental sustainability.

How Does an Advanced Eddy Current Separator Work?

The working principle of an advanced eddy current separator is elegantly simple yet remarkably effective. The machine uses a fast-spinning rotor with alternating polarity housed within a metallic drum. As the rotor spins, it creates strong eddy currents in the metals that pass through it. These currents generate opposing magnetic fields, which cause the non-ferrous metals to be repelled from the rest of the material flow.

Here’s a step-by-step breakdown of the process:

- Material Feed: The mixed material, which includes non-ferrous metals, is fed onto a conveyor belt.

- Magnetic Rotor: As the material passes over the magnetic rotor, eddy currents are induced in the non-ferrous metals.

- Separation: The repelled non-ferrous metals are thrown forward into a collection area, while the remaining materials fall off the conveyor belt at the end of the line.

- Collection: The separated non-ferrous metals are collected in a bin, ready for further processing or sale.

This process is crucial in industries like plastic recycling, where purity is paramount. The removal of metals like aluminum and copper ensures that the recycled PET is free from contaminants, thus increasing its quality and market value.

Applications of Eddy Current Separators

Eddy current separators are incredibly versatile and are used across various industries for different purposes. Some common applications include:

- Plastic Recycling: Removing non-ferrous metals from shredded plastic to ensure higher quality and value.

- Glass Recycling: Extracting metals from recycled glass to prevent contamination.

- Timber Processing: Separating metals from wood chips and sawdust.

- Electronic Scrap Recycling: Recovering valuable metals from e-waste.

- Automobile Shredding: Removing metals from shredded vehicles to separate valuable materials.

- Solid Waste Management: Enhancing the recovery of metals from municipal waste streams.

The widespread use of eddy current separators in these industries highlights their importance in improving recycling efficiency and the quality of the final recycled product.

Complementary Technologies

While the advanced eddy current separator is incredibly effective at removing non-ferrous metals, it works even better when used in conjunction with other metal separation technologies. For instance, ferromagnetic metals like iron and steel, which are not affected by eddy currents, can be efficiently removed using suspension magnetic separators or high-intensity roller separators. These systems ensure that both ferrous and non-ferrous metals are removed from the material stream, resulting in a cleaner and more valuable end product.

Additional Images

Conclusion

The advanced eddy current separator is an indispensable tool in modern recycling operations. Its ability to efficiently remove non-ferrous metals from various material streams not only enhances the value of recycled materials but also contributes to environmental sustainability by ensuring that metals are properly recovered and reused. Whether in PET bottle recycling or broader applications across multiple industries, investing in an advanced ECS is a step towards more efficient and profitable recycling processes.

For businesses looking to improve their recycling capabilities, the advanced eddy current separator offers an unmatched solution for non-ferrous metal separation. It is a key investment for any recycling operation aiming to enhance the quality of its output and its bottom line.

Inquire Now

To get the latest prices and lead times, send us a message using the form below.