Contents

Introduction

In the ever-evolving landscape of plastic recycling, the Innovative PP PE Plastic Film Shredding and Densifying Line stands out as a complete solution for transforming dirty bales of PP/PE films into densified products. These products are then ready for chemical applications or further processing into plastic granules. With standard capacities ranging from 200kg/h to 1000kg/h, this line offers a straightforward yet extremely efficient solution for your recycling needs.

@chat_machine PP PE Plastic Film Densifying Line♻️#plasticrecyclingmachine #plasticsqueezer #recyclingmachine #plasticwashingmachine ♬ original sound – Rumtoo Recycling Machinery

Working Principle

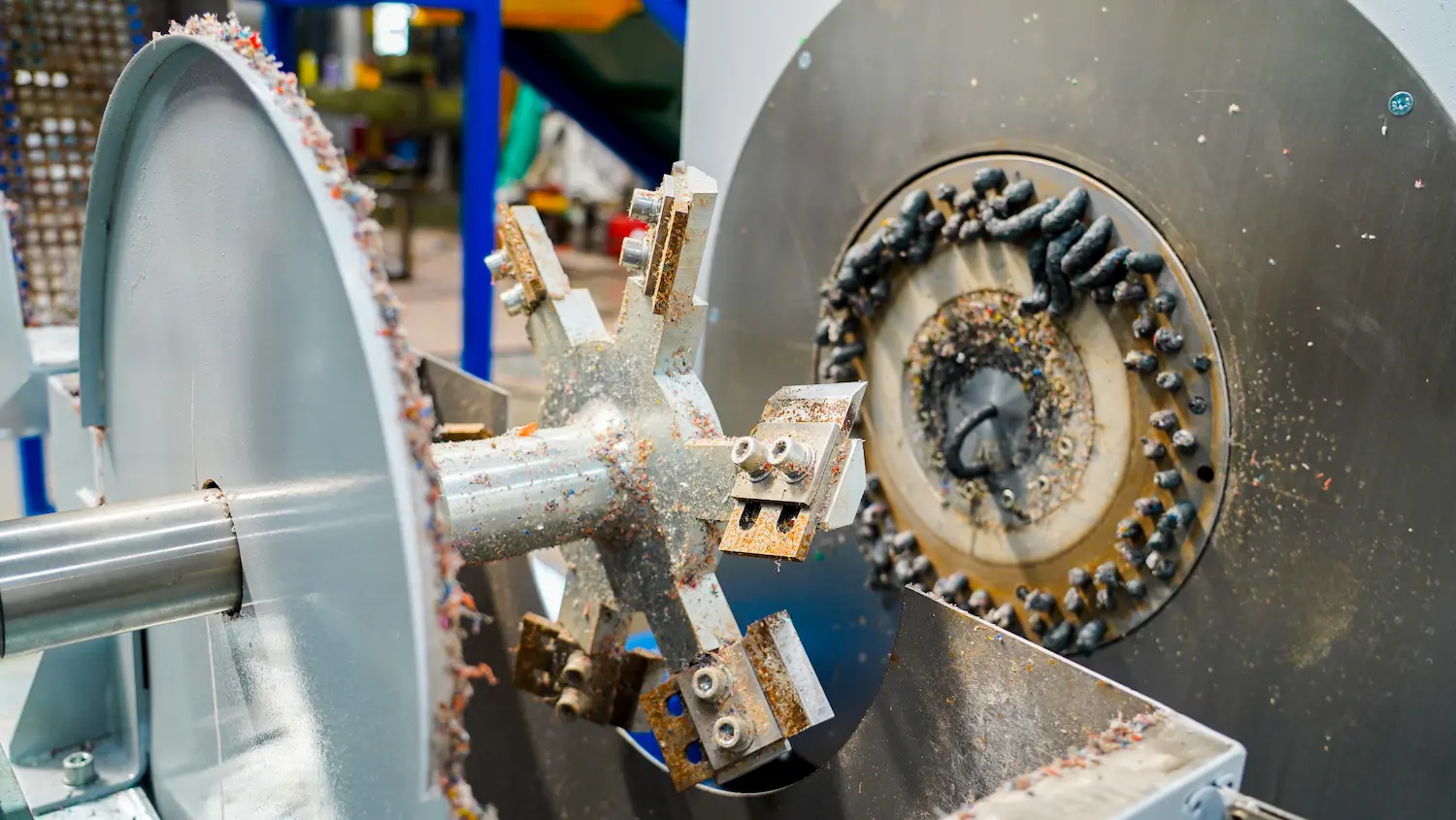

The process begins with a single-shaft shredder equipped with a movable hopper that breaks down compacted bales of plastic films. Once shredded, these films are conveyed to the Wet Granulator/Crusher. Here, heavy-duty knives rotating at high speeds cut the material into small flakes. A screen controls the size of these flakes, while water is sprayed into the cutting chamber to partially wash the material and act as a lubricant, reducing friction.

Technical Specifications

- Shredder: Single-shaft with movable hopper

- Wet Granulator/Crusher: Heavy-duty knives, screen size customisable

- Sink/Float Tank: Large tank for cleaning and contamination removal

- Squeezer: Increases material density to 350-410 kg/m3

| Capacity | 200 kg/hr | 500 kg/hr | 1000 kg/hr |

| Dimension | 25 x 5 x 5.5m | 28 x 6 x 5.5m | 35 x 8.5 x 5.5m |

| Operator | 2-3 | 2-3 | 2-3 |

| Installation Power | 196 KW | 215 KW | 401 KW |

Sink/Float Tank and Squeezer

The Sink/Float Tank serves as a cleaning station where rotating paddles propel the small pieces of film along a water tank. Contaminants like mud and small stones sink to the bottom and are removed. The clean plastic film then moves to the Squeezer, where it is densified into irregular pellets using a large screw and heaters. The density of the finished product dramatically increases to approximately 350-410 kg/m3

Conclusion

The Innovative PP PE Plastic Film Shredding and Densifying Line is more than just a set of machines; it’s a complete solution for your plastic film recycling needs. With its advanced components and efficient processing steps, this line is set to become the new trend in plastic recycling.

Warranty & Support

All our recycling machinery comes with a limited warranty. We also offer installation packages where our engineers travel to your facility to guide you through the installation process.

All of our products can be customized according to customer requirements.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.