Screw conveyors are pivotal in various industries, offering an array of designs tailored for different materials and applications. Our range includes single, twin, and triplet screw conveyors, as well as specialized models for water filtration. Each unit boasts high stability and wear-resistant spirals, with customization options available to meet specific conveyance needs.

Contents

Design Features of Screw Conveyors

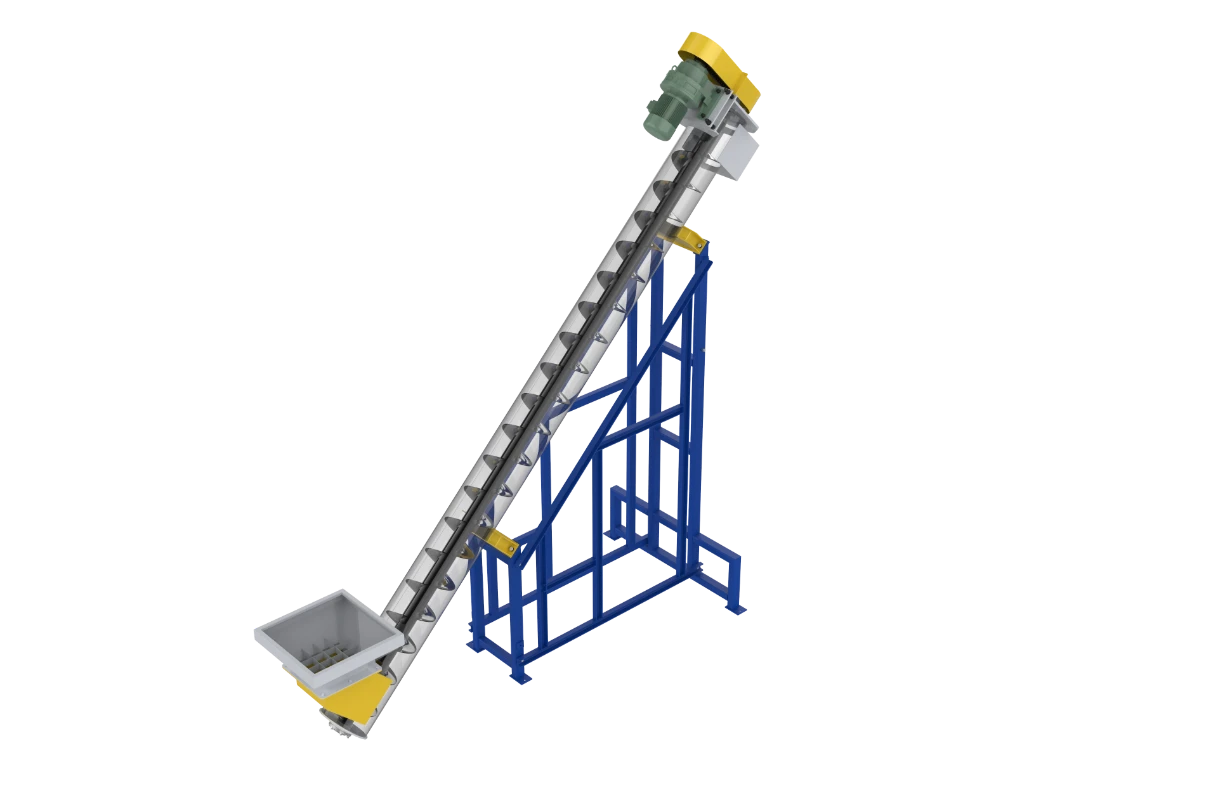

Central to the screw conveyor design is the helical screw blade, or auger, which rotates within a tube or trough. This rotation facilitates a continuous flow of material along the conveyor, making it possible to transport goods efficiently from one point to another. The versatility of the screw blade’s size, shape, and pitch allows for optimization based on the material type and application requirements. Screw diameters can vary significantly, with customization options to accommodate any space constraints.

Types of Screw Conveyors

Screw conveyors are designed to suit various operational needs:

• Horizontal Screw Conveyors: Ideal for moving materials either horizontally or at a slight incline.

• Vertical Screw Conveyors: Best for vertical material transport, from lower to higher elevations.

• Inclined Screw Conveyors: Used for angled material conveyance, typically from a hopper to machinery.

• Shaftless Screw Conveyors: Perfect for handling sticky or stringy materials, avoiding entanglement issues associated with traditional screw blades.

Applications Across Industries

Screw conveyors are integral to industries such as agriculture, food and beverage, chemical processing, and mining. They are employed in:

• Moving bulk materials like grains, powders, and pellets.

• Mixing operations, particularly in animal feed production.

• Metering tasks for ingredient batching in food production.

• Dewatering operations for sludge and other waste materials.

Advantages of Using Screw Conveyors

Screw conveyors provide numerous benefits:

• Versatility: Capable of handling diverse materials, from fine powders to large granules.

• Efficiency: They transport materials over long distances with minimal energy use.

• Low Maintenance: With fewer moving parts, screw conveyors are economical and require minimal upkeep.

• Customizability: Tailor-made to meet the specific requirements of different applications, ensuring optimal performance.

Screw conveyors are a reliable and efficient choice for material handling across various sectors. By leveraging their design flexibility and operational benefits, you can enhance your facility’s productivity and efficiency. Whether your aim is to transport, mix, or meter materials, screw conveyors are engineered to fulfill a broad spectrum of industrial needs.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.

Warranty

All recycling machines come with a 1 year limited warranty.

All of our products can be customized according to customer requirements.