Rigid Plastic Shredder Machines

An effective plastic shredder machine for processing large pieces of rigid plastics such as plastic lumps, purge from extruders, entire sheet rolls, and more.

Technical Parameters

| Shredder Model | Shaft Diameter (mm) | Moving Knife Qty. (pcs) | Fixed Knife Qty. (pcs) | Max Capacity (kg/h) | Main Power (kW) | Dimensions (mm) |

|---|---|---|---|---|---|---|

| RTM-2455 | 275 | 24 | 1 | 400 | 22 | 3250×1500×2350 |

| RTM-3063 | 275 | 30 | 1 | 500 | 30 | 3250×1750×2350 |

| RTM-3980 | 275 | 39 | 1 | 700 | 37 | 4150×1900×2450 |

| RTM-48100 | 315 | 48 | 1 | 900 | 45 | 4700×2550×2650 |

| RTM-57120 | 315 | 57 | 1 | 1200 | 55 | 5350×2850×2760 |

| RTM-75160 | 350 | 75 | 2 | 1300 | 75 | 5900×3050×2960 |

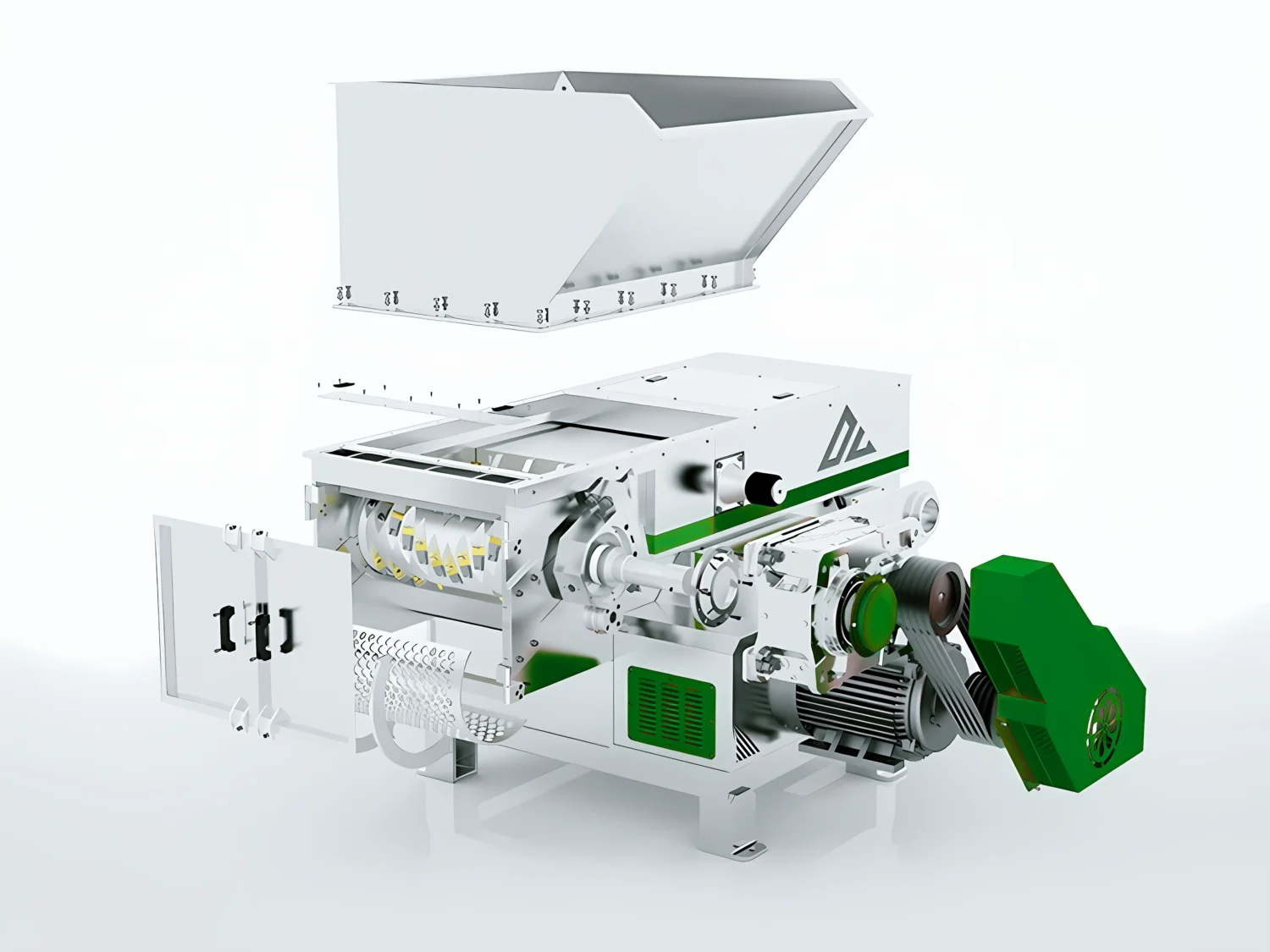

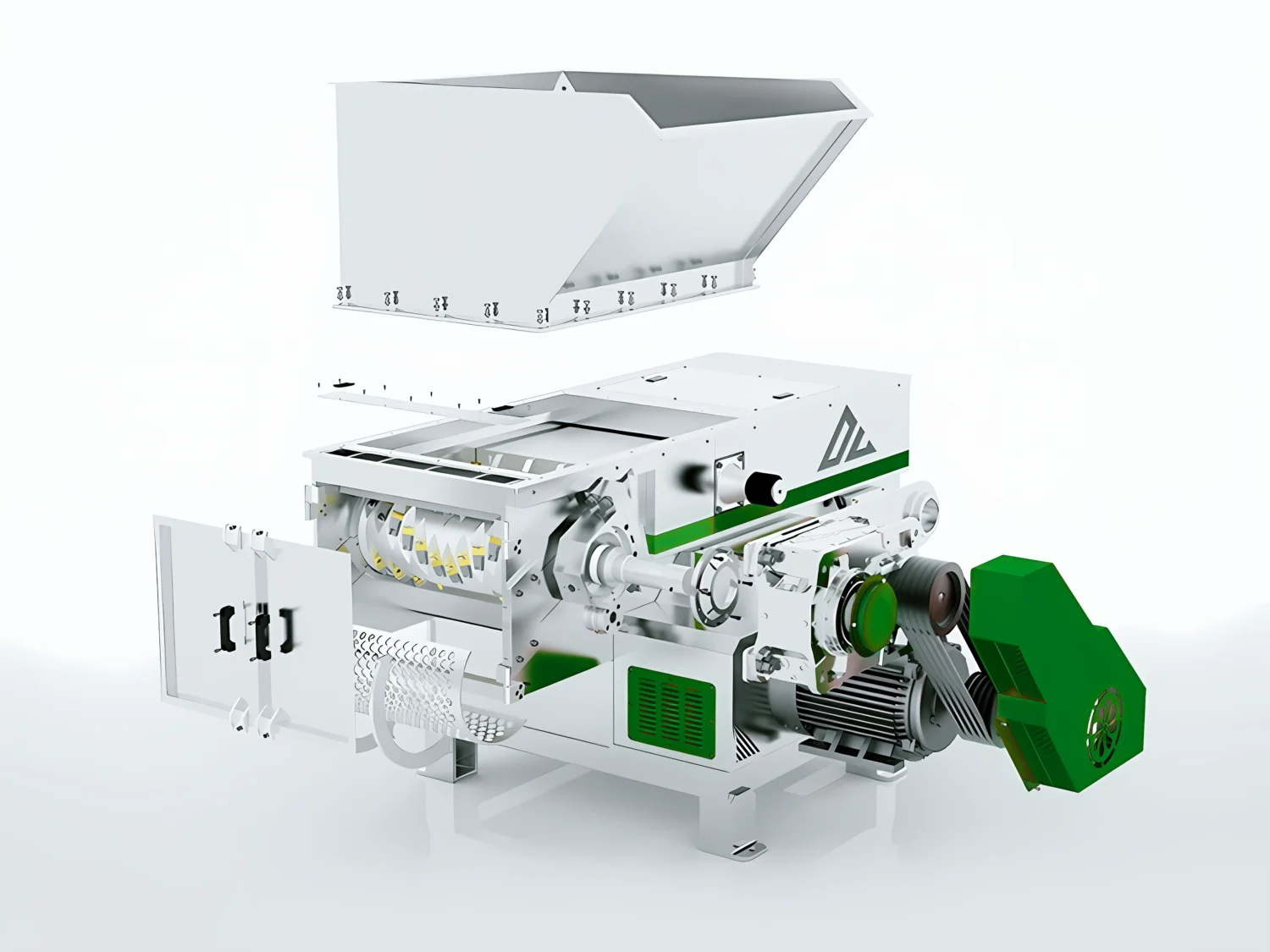

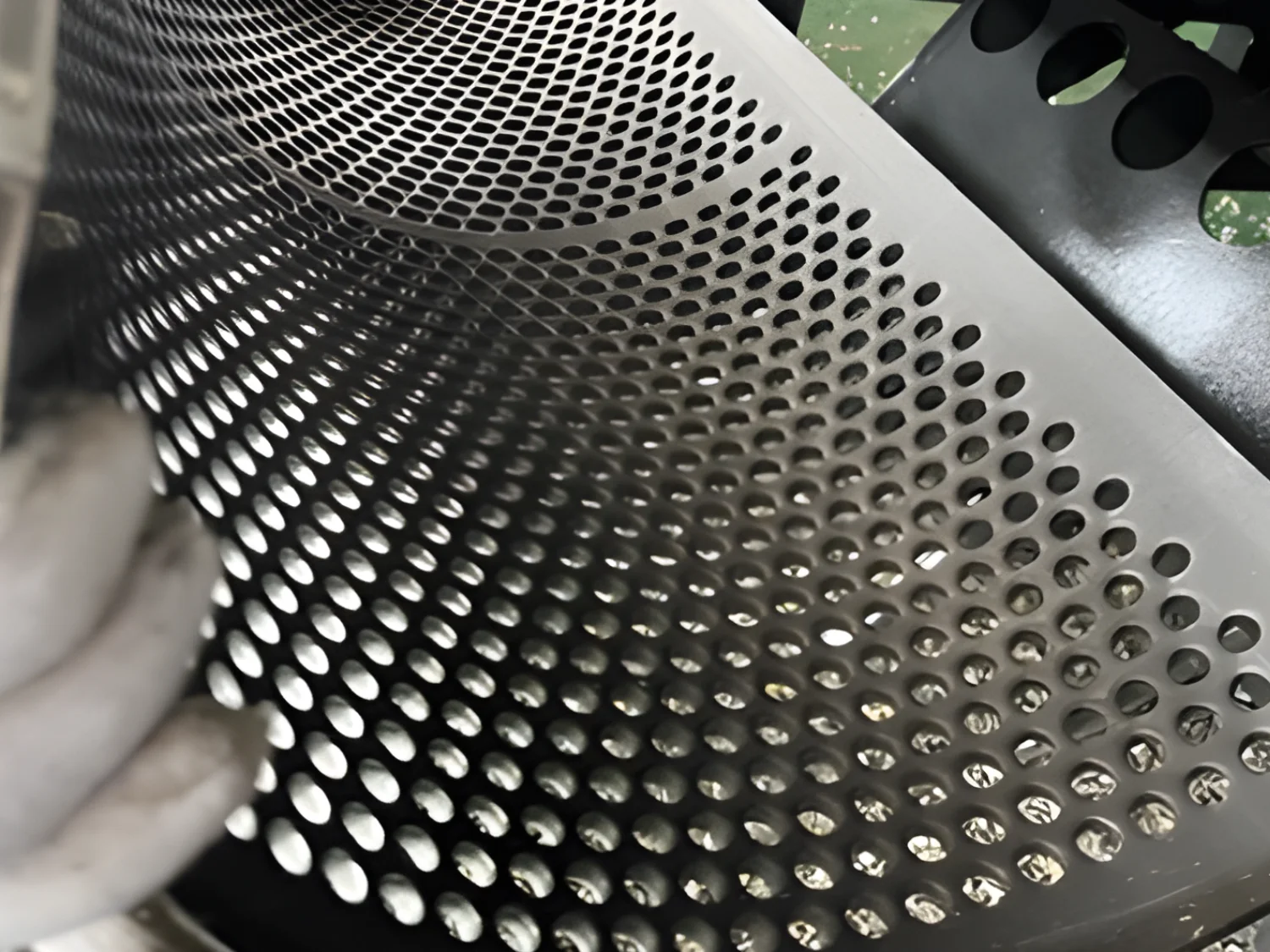

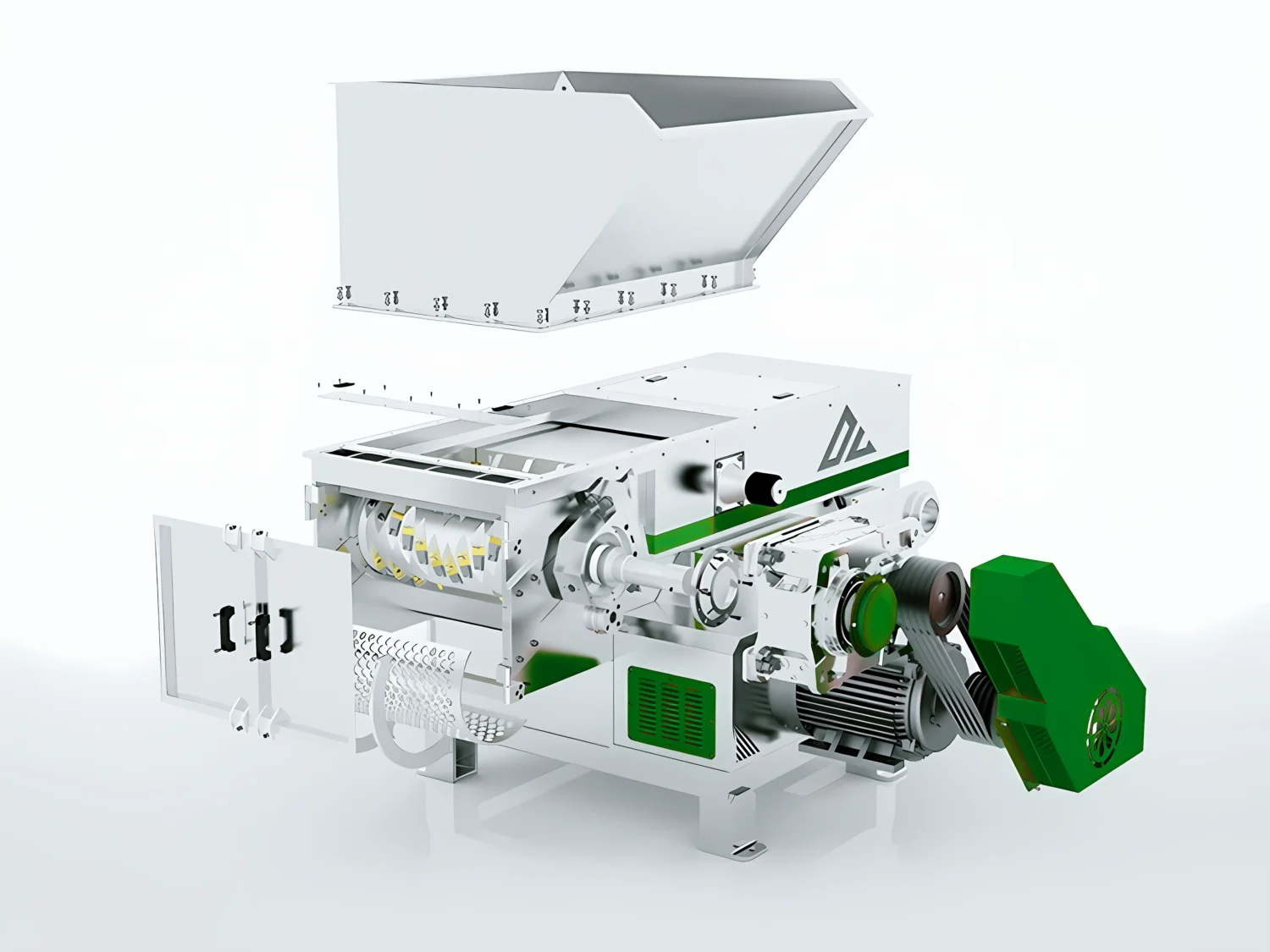

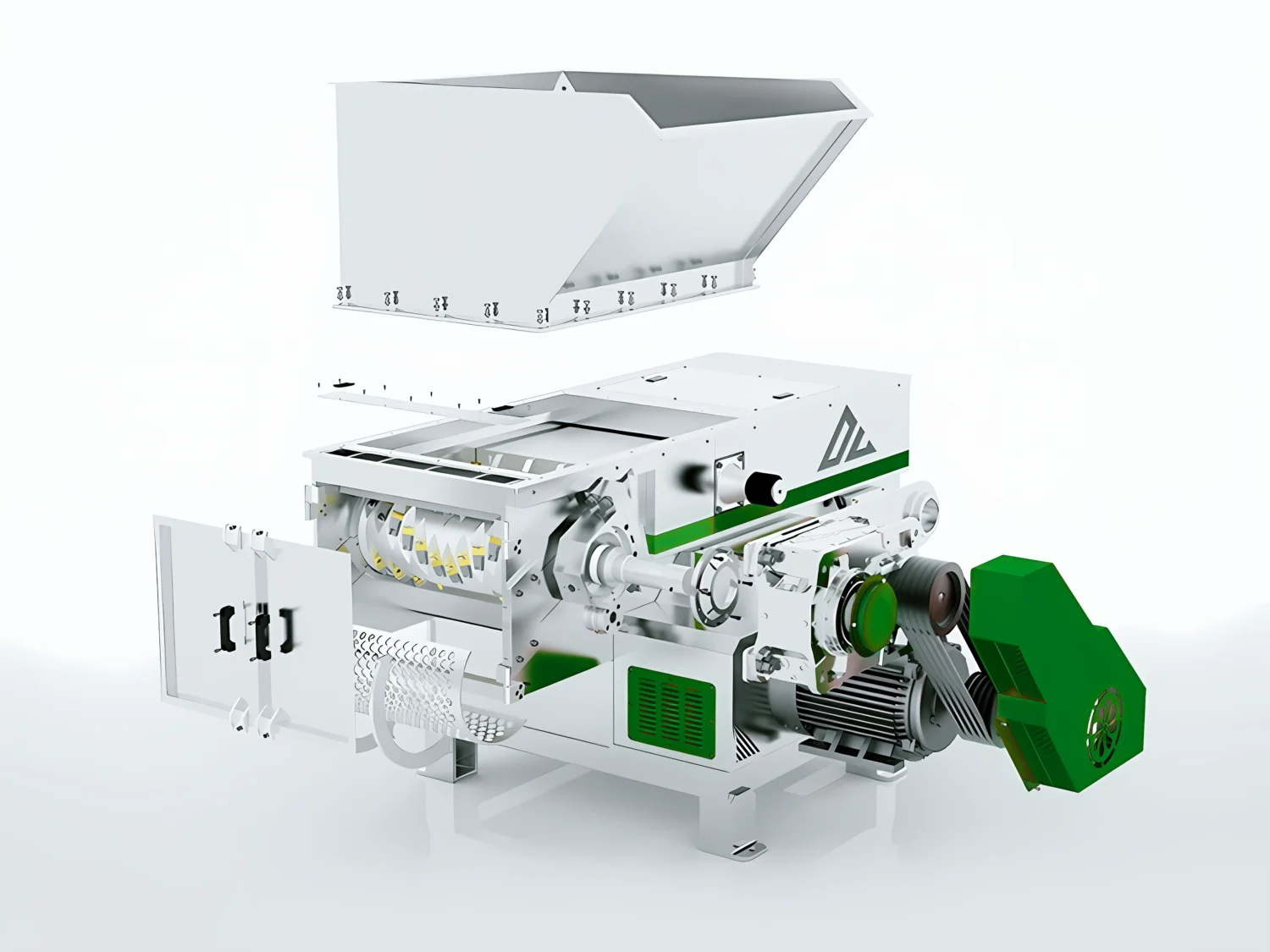

Product Display

Key Features of This Technology

1. Continuous Feeding, High Efficiency

Our shredder allows continuous feeding of rigid plastics, ensuring high shredding efficiency without interruptions. The advanced design prevents blockages, providing consistent operation.

2. Movable Hopper for Jam-Free Operation

The specially designed movable hopper ensures jam-free shredding, even with large and rigid plastic materials. This unique feature allows for smooth feeding without the risk of jamming, ensuring maximum throughput.

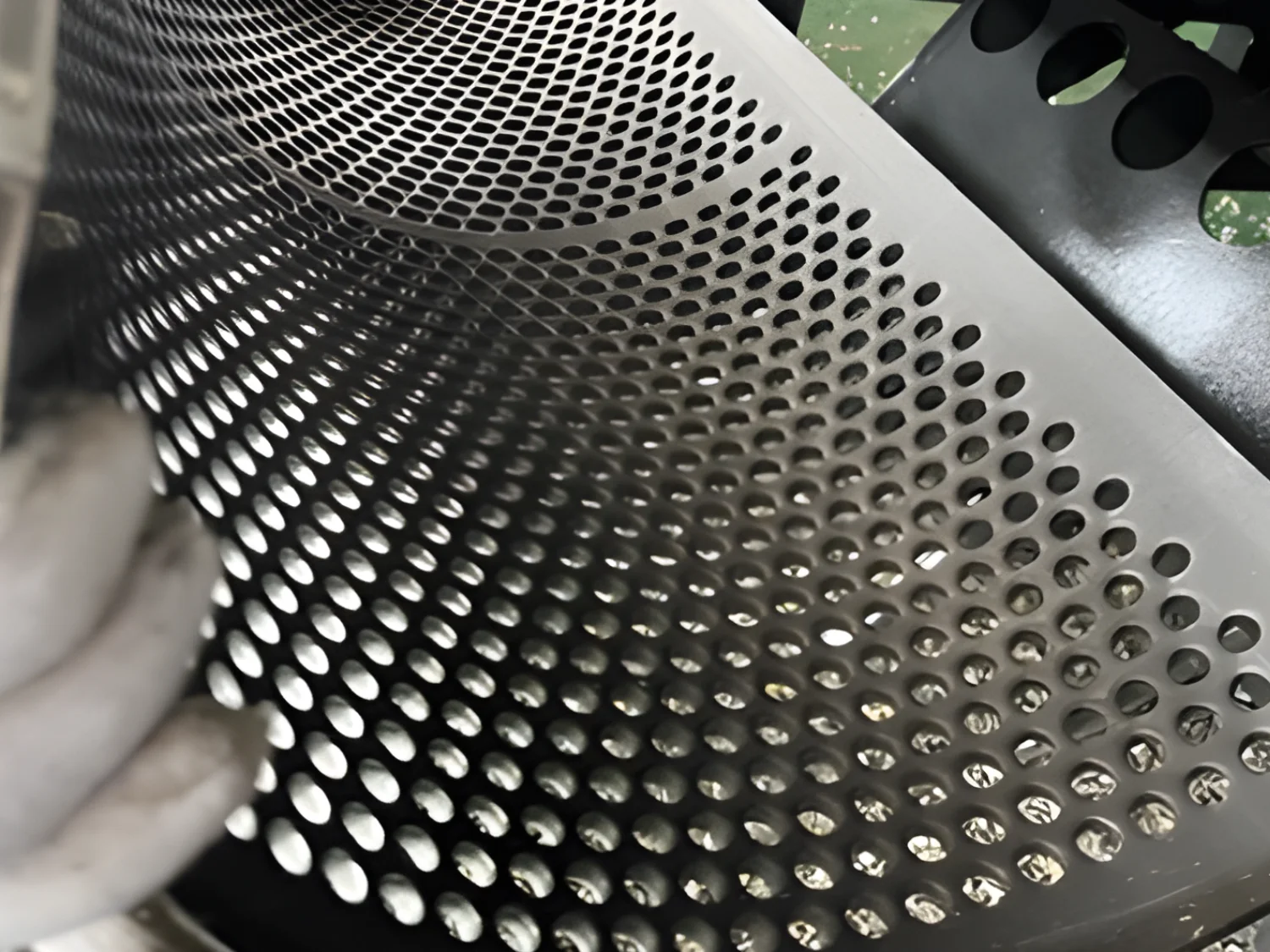

3. Large Rotor for Improved Productivity

The rotor is customized with a large rotating diameter to maximize the shredding contact surface, which significantly improves shredding productivity.

4. Advanced Transmission System

Transmission parts are connected by couplings to reduce vibrations, protect the main shaft and reducer, and prevent force-induced damage.

5. PLC-Controlled Automated Operation

Equipped with a self-programming PLC system that controls start, stop, forward rotation, and overload protection, this shredder provides a fully automated, safe, and stable work environment.

Applications of This Technology

1. Large Diameter PE/PVC Pipes, Board

Effectively shreds large, rigid plastic pipes and boards made from materials like PE and PVC, ensuring smooth operation without jamming.

2. PP, PC, ABS Lumps

Designed to handle bulky lumps of rigid plastics such as PP, PC, and ABS, making it ideal for processing production scrap and purge materials.

3. Pallet

Efficiently processes rigid plastic pallets, reducing them into smaller, manageable pieces for recycling or disposal.

4. Waste Wire and Cable

Capable of shredding plastic coatings from wires and cables, making it a versatile solution for recycling a wide range of industrial materials.

5. Waste Metal, Glass Fiber, Carbon Fiber

Handles composite materials, including glass fiber, carbon fiber, and certain types of metal, separating the rigid plastic components for further processing.

Whether dealing with large, rigid plastic pipes or composite materials, this shredder provides a reliable solution for a wide array of recycling needs.

Rigid Plastic Shredder Machines

An effective plastic shredder machine for processing large pieces of rigid plastics such as plastic lumps, purge from extruders, entire sheet rolls, and more.

Technical Parameters

| Shredder Model | Shaft Diameter (mm) | Moving Knife Qty. (pcs) | Fixed Knife Qty. (pcs) | Max Capacity (kg/h) | Main Power (kW) | Dimensions (mm) |

|---|---|---|---|---|---|---|

| RTM-2455 | 275 | 24 | 1 | 400 | 22 | 3250×1500×2350 |

| RTM-3063 | 275 | 30 | 1 | 500 | 30 | 3250×1750×2350 |

| RTM-3980 | 275 | 39 | 1 | 700 | 37 | 4150×1900×2450 |

| RTM-48100 | 315 | 48 | 1 | 900 | 45 | 4700×2550×2650 |

| RTM-57120 | 315 | 57 | 1 | 1200 | 55 | 5350×2850×2760 |

| RTM-75160 | 350 | 75 | 2 | 1300 | 75 | 5900×3050×2960 |

Product Display

Key Features of This Technology

1. Continuous Feeding, High Efficiency

Our shredder allows continuous feeding of rigid plastics, ensuring high shredding efficiency without interruptions. The advanced design prevents blockages, providing consistent operation.

2. Movable Hopper for Jam-Free Operation

The specially designed movable hopper ensures jam-free shredding, even with large and rigid plastic materials. This unique feature allows for smooth feeding without the risk of jamming, ensuring maximum throughput.

3. Large Rotor for Improved Productivity

The rotor is customized with a large rotating diameter to maximize the shredding contact surface, which significantly improves shredding productivity.

4. Advanced Transmission System

Transmission parts are connected by couplings to reduce vibrations, protect the main shaft and reducer, and prevent force-induced damage.

5. PLC-Controlled Automated Operation

Equipped with a self-programming PLC system that controls start, stop, forward rotation, and overload protection, this shredder provides a fully automated, safe, and stable work environment.

Applications of This Technology

1. Large Diameter PE/PVC Pipes, Board

Effectively shreds large, rigid plastic pipes and boards made from materials like PE and PVC, ensuring smooth operation without jamming.

2. PP, PC, ABS Lumps

Designed to handle bulky lumps of rigid plastics such as PP, PC, and ABS, making it ideal for processing production scrap and purge materials.

3. Pallet

Efficiently processes rigid plastic pallets, reducing them into smaller, manageable pieces for recycling or disposal.

4. Waste Wire and Cable

Capable of shredding plastic coatings from wires and cables, making it a versatile solution for recycling a wide range of industrial materials.

5. Waste Metal, Glass Fiber, Carbon Fiber

Handles composite materials, including glass fiber, carbon fiber, and certain types of metal, separating the rigid plastic components for further processing.

Whether dealing with large, rigid plastic pipes or composite materials, this shredder provides a reliable solution for a wide array of recycling needs.