PVC Recycling Machine technology plays a crucial role in the circular economy, particularly in recycling PVC profiles. Companies like Deceuninck are leading the way by recycling PVC window profiles, transforming them into new products while maintaining the original quality. In this article, we’ll explore the importance of PVC recycling, how recycling machines work, and the benefits of reusing PVC profiles.

Why Recycle PVC Profiles?

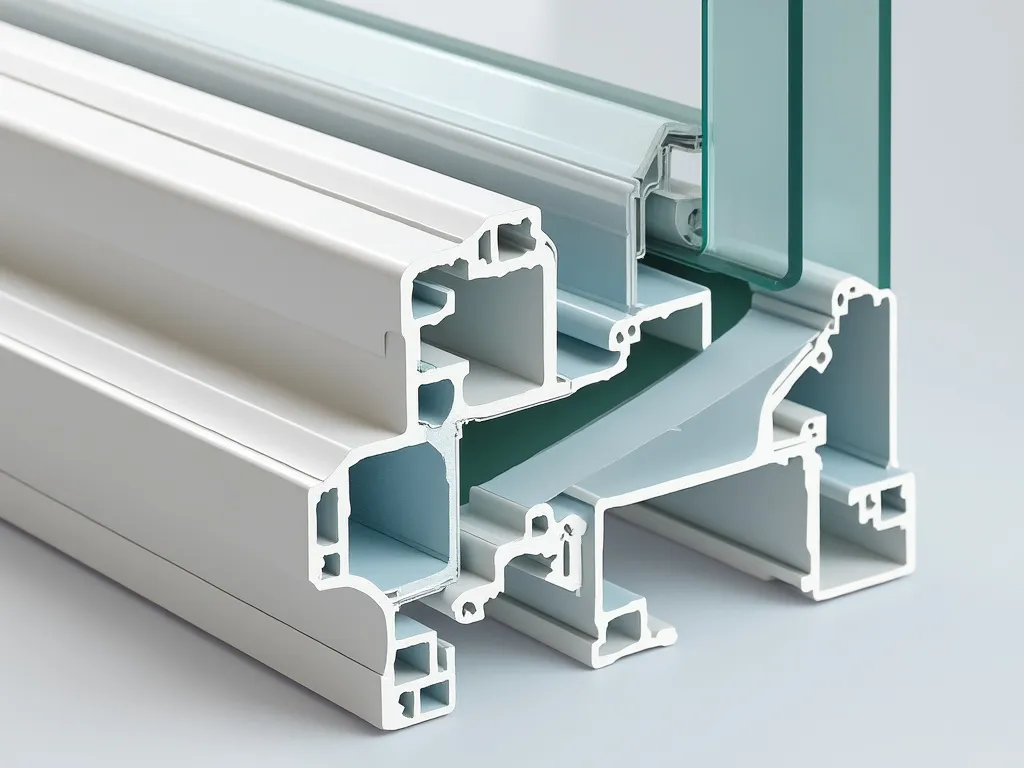

PVC, or polyvinyl chloride, is a highly durable plastic that is widely used in construction, especially for window and door profiles. Recycling these PVC profiles has numerous advantages:

1. Environmental Benefits

- Recycling PVC profiles significantly reduces waste going to landfills or incinerators. In facilities like Deceuninck’s, millions of PVC profiles are saved from landfills annually.

- For every ton of recycled PVC used, the industry saves 2-3 tons of CO2 emissions, making a substantial impact on reducing the carbon footprint.

2. Resource Efficiency

- PVC profiles can be recycled up to eight times without losing performance or quality, giving them a total lifespan of over 300 years.

- Recycled PVC requires only 10% of the energy needed to produce new PVC, making it a more sustainable and energy-efficient choice.

How PVC Recycling Machines Work

The core of PVC recycling lies in PVC Recycling Machines, which are designed to process old PVC profiles and convert them into reusable material. Here’s how these machines contribute to recycling:

1. Collection and Pre-Treatment

- The process begins with collecting old PVC profiles, often sourced from construction sites, renovation projects, or industrial off-cuts.

- Pre-treatment involves removing contaminants such as glass, rubber, or metals before feeding the PVC into the recycling machine.

2. Mechanical Grinding and Washing

- PVC Recycling Machines grind the profiles into small particles, called flakes, making them easier to process further.

- The flakes are thoroughly washed to remove any remaining impurities, ensuring the purity of the recycled material.

3. Granulation and Reprocessing

- The cleaned PVC flakes are melted and reformed into granulate, which is the raw material for making new PVC products.

- This recycled granulate is then used to manufacture new PVC profiles, completing the recycling loop.

The Role of PVC Recycling Machines in the Circular Economy

1. Sustainable Manufacturing

- By using recycled PVC as the primary raw material, manufacturers reduce reliance on virgin PVC, conserving resources and energy.

- PVC Recycling Machines enable efficient processing of different types of PVC profiles, even those with added components like glass fiber.

2. Improved Product Quality

- Thanks to advanced PVC recycling technology, the recycled material retains high quality, ensuring that new products meet industry standards and performance criteria.

Challenges in PVC Profile Recycling

1. Mixed Materials

- PVC profiles often contain additional materials like metal reinforcements or seals, which can complicate the recycling process.

- Advanced sorting and separation technologies are necessary to handle these complexities effectively.

2. Color Variations

- PVC profiles come in a range of colors, which can affect the quality of recycled material. PVC Recycling Machines, however, are designed to handle color variations efficiently, ensuring consistent results.

Conclusion

PVC Recycling Machines are transforming the way PVC profiles are recycled, promoting a sustainable and energy-efficient circular economy. By maximizing the reuse of PVC profiles, we can significantly reduce waste, conserve resources, and lower carbon emissions. Investing in these machines and improving recycling processes will continue to play a key role in achieving a greener, more sustainable future.