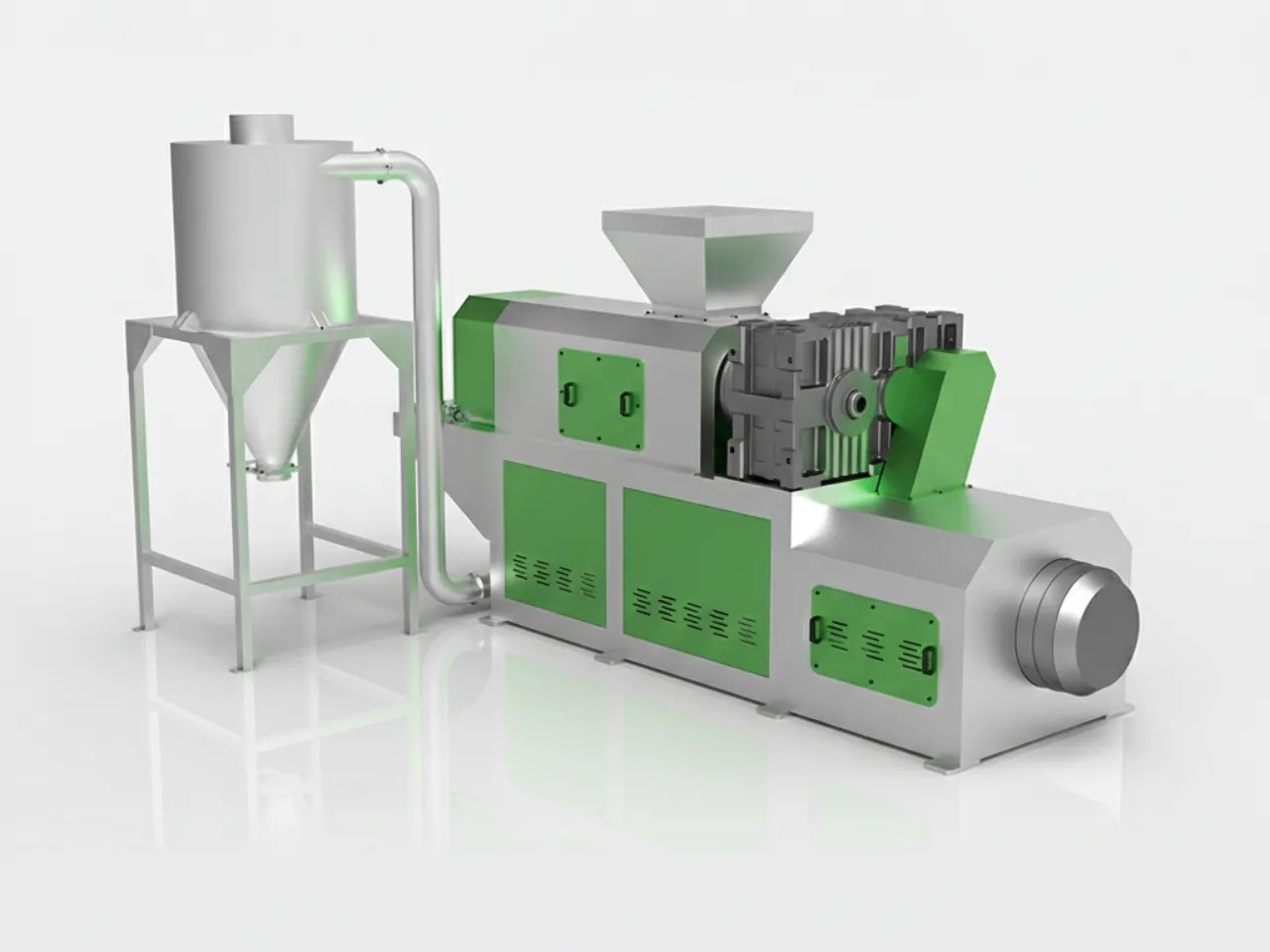

Mechanical Dewatering Equipment

Screw Press Dewatering System for PE/PP Film Washing Lines

Our screw press dewatering system is engineered to remove water from wet plastic film and other material streams after washing. It delivers strong moisture reduction with lower energy use than thermal heating, helping stabilize downstream drying and pelletizing.

What Is a Screw Press Dewatering System?

A screw press dewatering machine uses a rotating screw shaft to compress wet material inside a perforated barrel. As pressure increases along the press, free water is forced out through the screen and drained away, while the compacted material is discharged at the end.

In plastic recycling, this is one of the most effective ways to reduce water content after washing—especially for PE film, PP film, raffia, woven bags, and similar light materials that carry surface water.

Key Benefits of Our Industrial Screw Press Dewatering Machine

- Effective moisture extraction for washed plastic film, helping achieve stable extrusion and pellet quality.

- Lower operating cost by reducing the duty cycle of downstream thermal drying (when used).

- Continuous operation with adjustable compression/back-pressure for different materials and capacities.

- Robust construction suitable for industrial recycling, wastewater-heavy processes, and non-plastic applications.

Applications

Our screw press dewatering system is commonly used in:

- Plastic recycling lines: PE/PP film washing lines, woven bag & raffia washing lines, rinsing and drainage stages.

- Industrial processes: food processing, paper & pulp, sewage and sludge dewatering, and other wet material handling.

Related systems: PP/PE Recycling Washing Line and Recycling Washing Systems.

Working Principle

At the core of our screw press dewatering system is a screw shaft with a progressively increasing diameter. Wet plastic is introduced via a vertical feeder into a thick-walled outer tube lined with perforations for water drainage. A typical industrial recycling screw press is 4–6 meters in length, and can be adjusted to suit your capacity and layout.

As the screw rotates, it advances the material forward. With the increasing screw diameter, the material becomes more compacted against the casing wall. Water is squeezed out and drains through the perforations.

Near the discharge, the screw diameter approaches the inner diameter of the casing, creating a narrow gap that generates higher pressure. This is how the material exits in a dewatered state. With correct sizing and settings, moisture can often be reduced to below 15%.

Typical Technical Specifications

Final specifications depend on your material, capacity, and target moisture. Ask for a configured quotation.

| Parameter | Typical Range | Notes |

|---|---|---|

| Application | Plastic film (PE/PP), light plastics, wet streams | Best for materials carrying surface water after washing |

| Machine length | 4–6 m | Custom lengths available |

| Discharge moisture | < 15% (typical) | Depends on material, feed, and line layout |

| Screen / barrel | Perforated drainage barrel | Hole size and open area selected per material |

| Drive | Gear motor with stable torque | Optional VFD for speed control |

How to Integrate in a Washing Line

A screw press is typically placed after rinsing and before final drying or pelletizing. By removing free water mechanically, it reduces the load on centrifugal dryers and thermal dryers and improves overall line stability.

- For PE/PP film: often used after friction washing + rinse tanks to quickly remove surface water.

- For higher moisture targets: combine screw press + centrifugal dryer and/or thermal drying.

- For compact layouts: consider a dedicated squeezer dewatering/drying machine.

FAQ

Can a screw press dewatering system handle soft PE film?

Yes. Screw pressing is widely used for PE/PP film streams after washing, especially when you need strong mechanical water removal before drying or pelletizing.

What affects the dewatering performance most?

Material type, feed consistency, contamination, screen selection, screw speed, and discharge back-pressure all impact final moisture. Proper sizing to your throughput is critical.

Is it suitable for sewage/sludge dewatering?

Screw presses are broadly used in sewage treatment and sludge dewatering. For those applications, the configuration may differ from plastic film designs—share your material details for the right recommendation.

Inquire Now

To get the latest price, lead time, and a recommended configuration, send us your material type, capacity (kg/h), and moisture target using the form below.