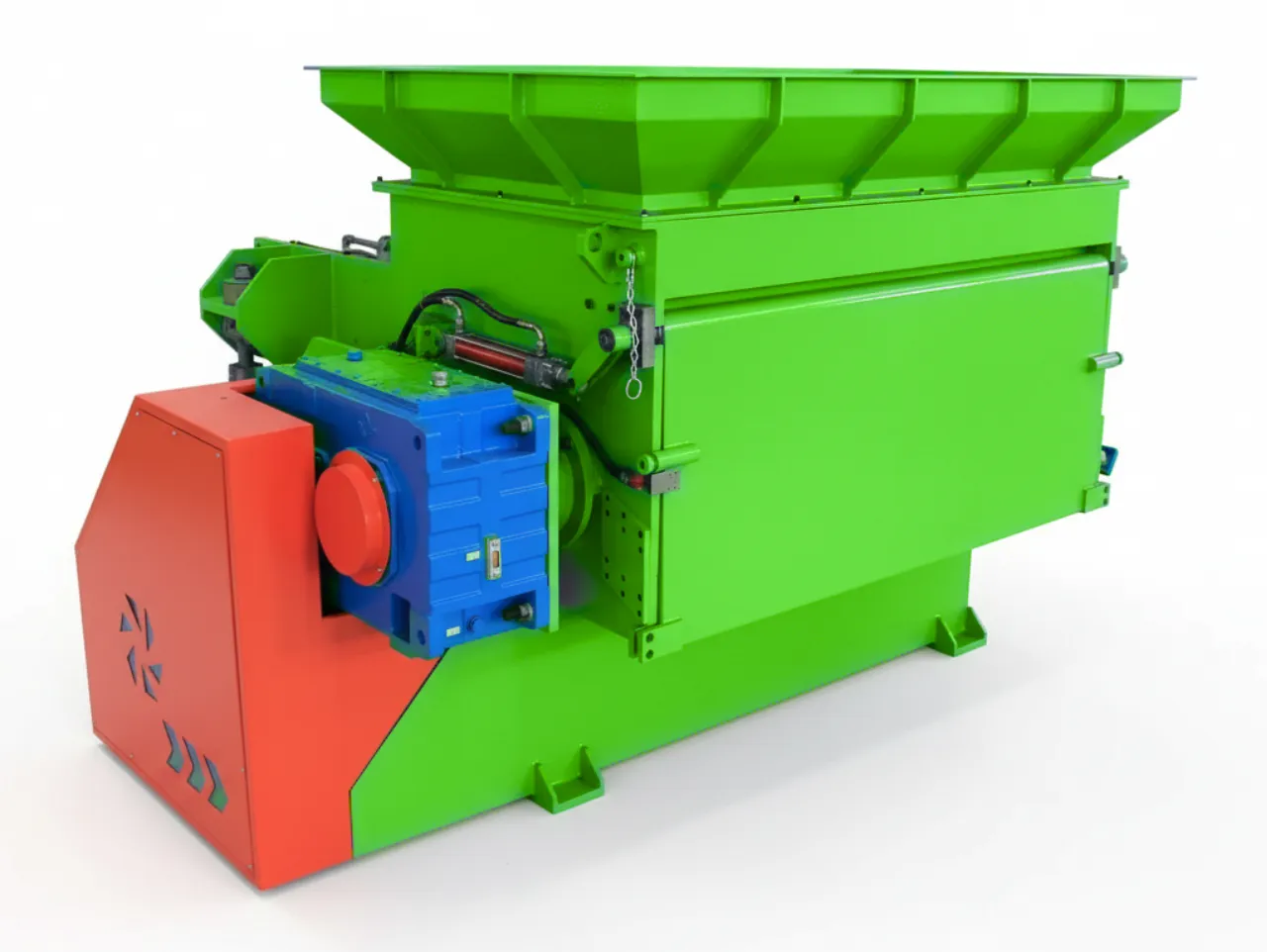

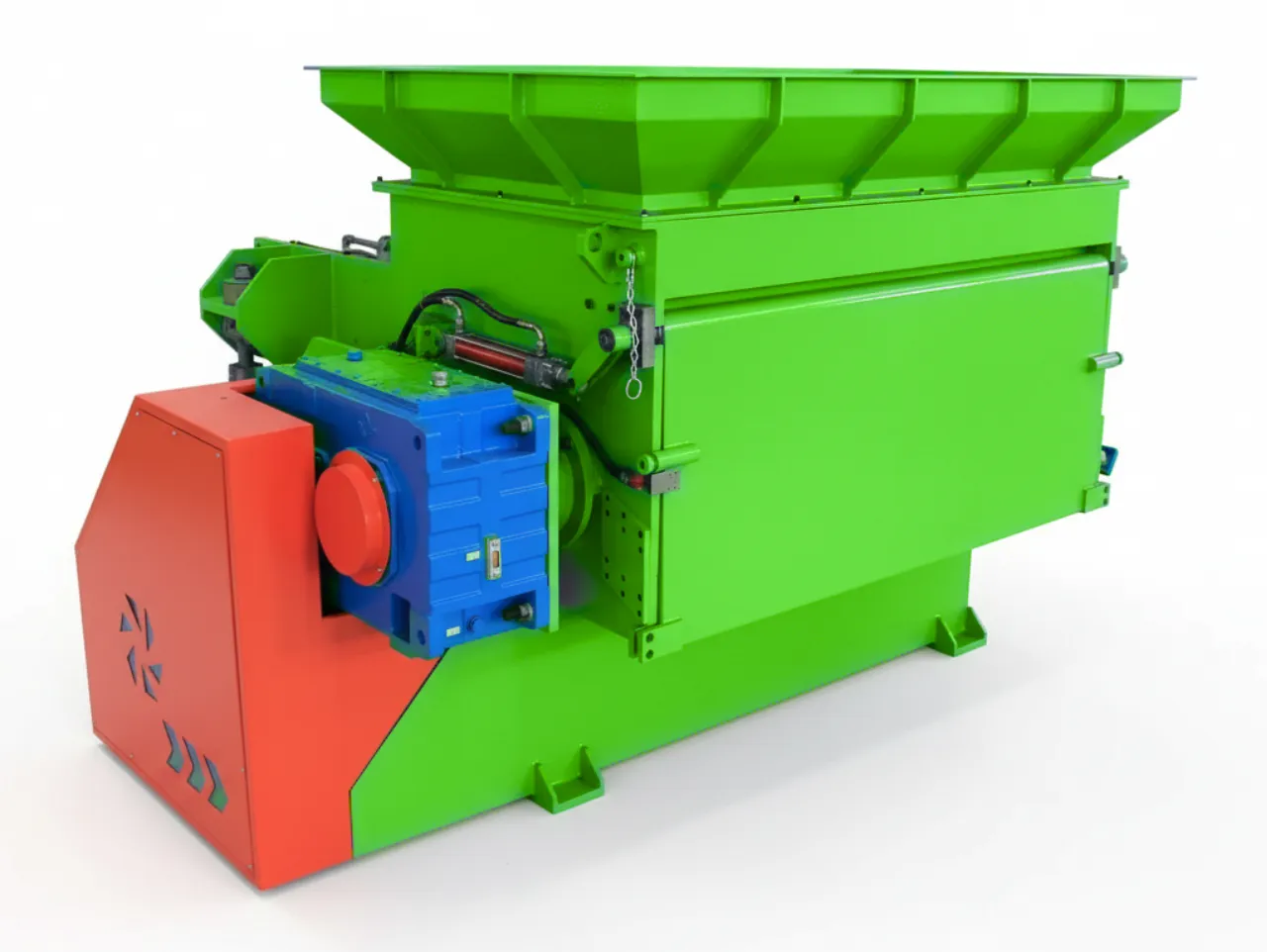

Двухвальный измельчитель для Эластичные пластмассы и резина

Крупные куски эластичных пластиков и резины сложно разрезать. Наш двухвальный измельчитель специально разработан для этой задачи, используя два вращающихся в противоположных направлениях вала для захвата и разрывания таких материалов, как автомобильные шины, силикон, ТПЭ и тюки ЭВА. Он обеспечивает высокое крутящее усилие и экономичное решение для эффективного измельчения материалов.

Принцип работы

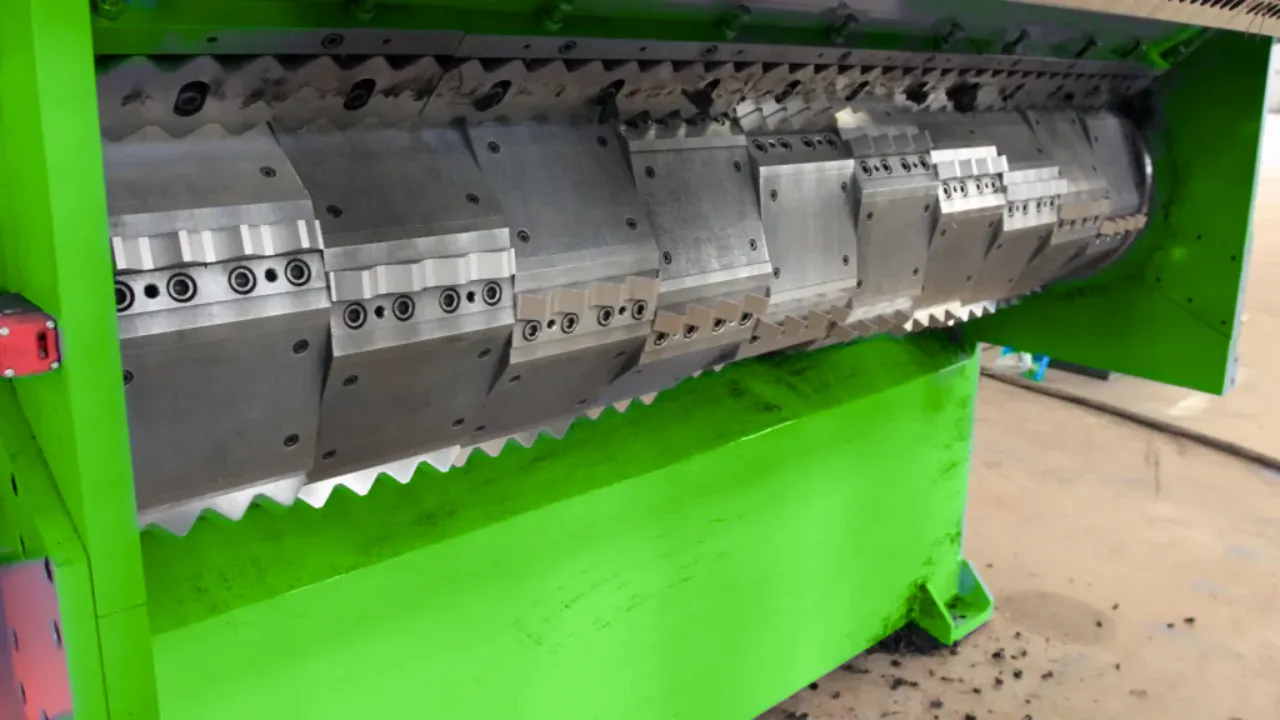

Эта машина использует два шестигранных вала, оснащенных переплетающимися режущими дисками, для обработки материала. Вращаясь на низких скоростях с высоким крутящим моментом, загнутые лезвия прочно захватывают резину или эластичный пластик, втягивая его в режущую камеру. Затем материал разрезается и разрывается между противоположно расположенными лезвиями. Этот двухвальный механизм обеспечивает непрерывную подачу и особенно эффективен для обработки крупногабаритных предметов, таких как шины, которые могут отскочить от одновального ротора. Интеллектуальная функция автоматического реверса предотвращает заклинивание, изменяя направление вращения валов при обнаружении перегрузки.

Ключевая особенность

-

Прочные отрезные диски

Зацепляющиеся лезвия изготовлены из высококачественной легированной стали (SKD11 или D2), подвергнутой термообработке для обеспечения максимальной износостойкости и сохранения остроты кромки.

-

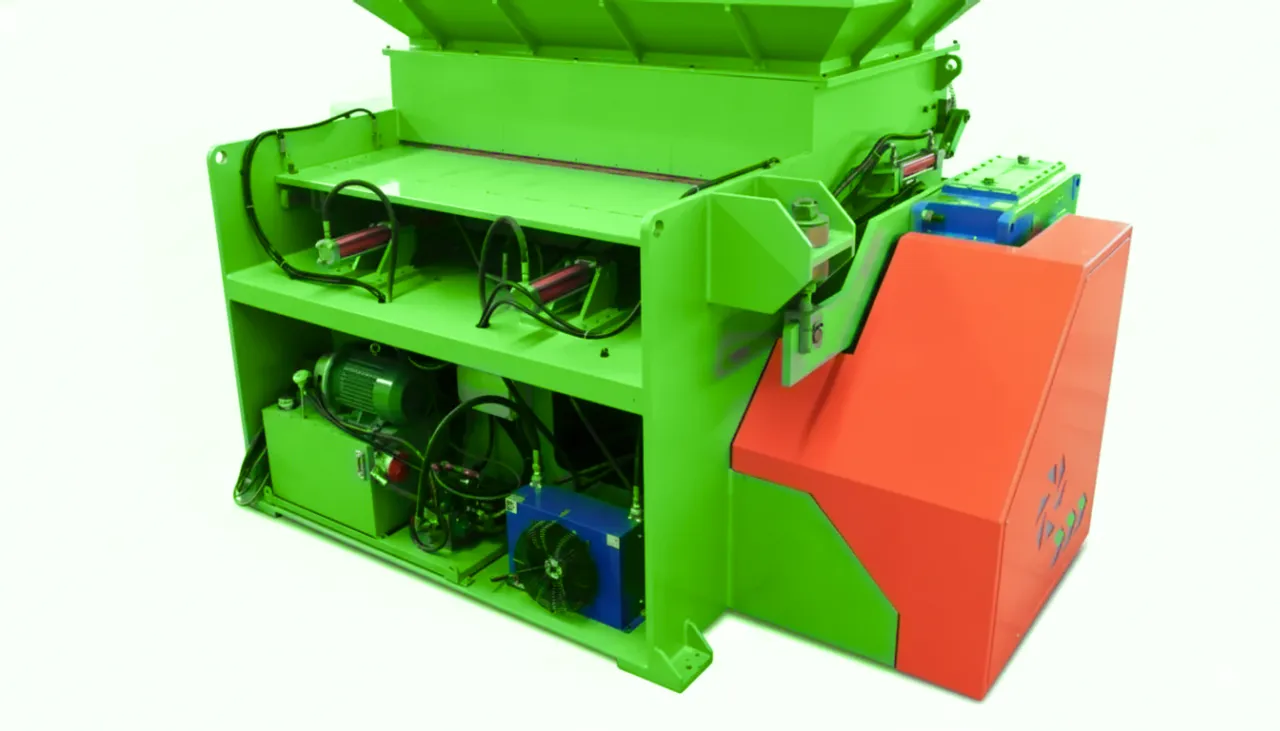

Раздельная конструкция корпуса

Наша конструкция с разъемным корпусом обеспечивает удобный доступ к обоим вращающимся валам и упрощает их обслуживание, что облегчает замену лезвий и техническое обслуживание.

-

Превосходная герметичность

Подшипники этой машины имеют многослойную герметизацию, предотвращающую загрязнение и защищающую трансмиссию даже в пыльной или влажной среде.

-

Система автореверса

Оснащен интеллектуальной системой ПЛК, которая автоматически меняет направление вращения валов при обнаружении перегрузки, предотвращая заклинивание и защищая двигатель.

-

Высокомоментный привод

Благодаря мощным редукторам, двойные валы обеспечивают огромный крутящий момент на низких скоростях, легко измельчая твердые материалы, такие как шины, без остановки двигателя.

Технические характеристики

| Модель | Мощность двигателя | Диаметр вала | Скорость вращения | Емкость |

|---|---|---|---|---|

| БС-1000 | 45 кВт | ⌀450 мм | 55 об/мин | 1000 кг/ч |

| БС-2000 | 110 кВт | ⌀500 мм | 45 об/мин | 3000 кг/ч |

| БС-3000 | 2x 110 кВт | ⌀550 мм | 40 об/мин | 5000 кг/ч |

*Доступна сертификация CE. *Более крупные и мощные модели доступны по запросу.

Гарантия и установка

От ввода в эксплуатацию до послепродажного обслуживания мы предоставляем полный пакет услуг, чтобы ваша производственная линия работала надежно.

Гарантийное покрытие

- Ограниченная гарантия сроком на 1 год на основные механические и электрические компоненты.

- Удалённая диагностика и приоритетное техническое обслуживание в течение гарантийного периода.

- Расходные материалы и изнашиваемые детали могут поставляться в соответствии с рекомендованными планами по поставке запасных частей.

Монтаж и ввод в эксплуатацию

- Инструкции перед установкой, включая планировку, инженерные коммуникации и контрольный список для фундамента.

- Оказание технической поддержки при вводе в эксплуатацию на месте или удаленно, включая настройку рабочих параметров.

- Обучение операторов по вопросам запуска, безопасной эксплуатации, ежедневных проверок и технического обслуживания.

Часто задаваемые вопросы

Наш двухвальный измельчитель превосходно справляется с обработкой твердых, эластичных и объемных материалов. Он специально разработан для целых автомобильных и грузовых шин, больших тюков резины, силиконовых отходов, обрезков TPE/TPR, пластиковых бочек и даже электронных отходов. Двухвальная конструкция обеспечивает непрерывное захватывание и разрывание материала, предотвращая его отскок, как это произошло бы при использовании одновального ротора.

Каждая машина оснащена интеллектуальной системой управления ПЛК с автоматической логикой реверса. Если измельчитель сталкивается с не подлежащим измельчению объектом или испытывает чрезмерную нагрузку, валы автоматически останавливаются и меняют направление вращения, чтобы устранить засор и защитить двигатель, валы и лезвия от повреждений. Этот процесс автоматически повторяется до тех пор, пока препятствие не будет устранено или машина не остановится в целях безопасности.

Режущие диски изготавливаются из высококачественной высоколегированной стали (например, SKD11 или D2), прошедшей термообработку для достижения оптимальной твердости и износостойкости. Поскольку двухвальные измельчители работают на низких скоростях с высоким крутящим моментом, износ лезвий значительно ниже по сравнению с высокоскоростными грануляторами, что приводит к увеличению срока службы и снижению частоты технического обслуживания.

Первичный размер частиц на выходе (ширина полос) определяется толщиной режущих лезвий (например, 20 мм, 40 мм или нестандартных размеров). Хотя длина измельченных частиц варьируется, ширина остается постоянной в зависимости от выбранного лезвия. Если вам требуется определенный однородный размер мелких частиц (например, гранулы 10-12 мм), мы рекомендуем подавать полученный материал во вторичный гранулятор или дробилку.

Двухвальные измельчители известны своей относительно тихой работой благодаря низкой скорости вращения. В отличие от высокоскоростных грануляторов, которые создают значительный шум от ударной резки, режущее действие низкоскоростного измельчителя производит гораздо меньший уровень шума, что делает его подходящим для стандартных промышленных условий без чрезмерного шумового загрязнения.

Узнать сейчас

На все наши машины для переработки отходов предоставляется ограниченная гарантия сроком на 1 год. Чтобы узнать актуальные цены и сроки поставки, пожалуйста, отправьте нам сообщение, используя форму ниже.