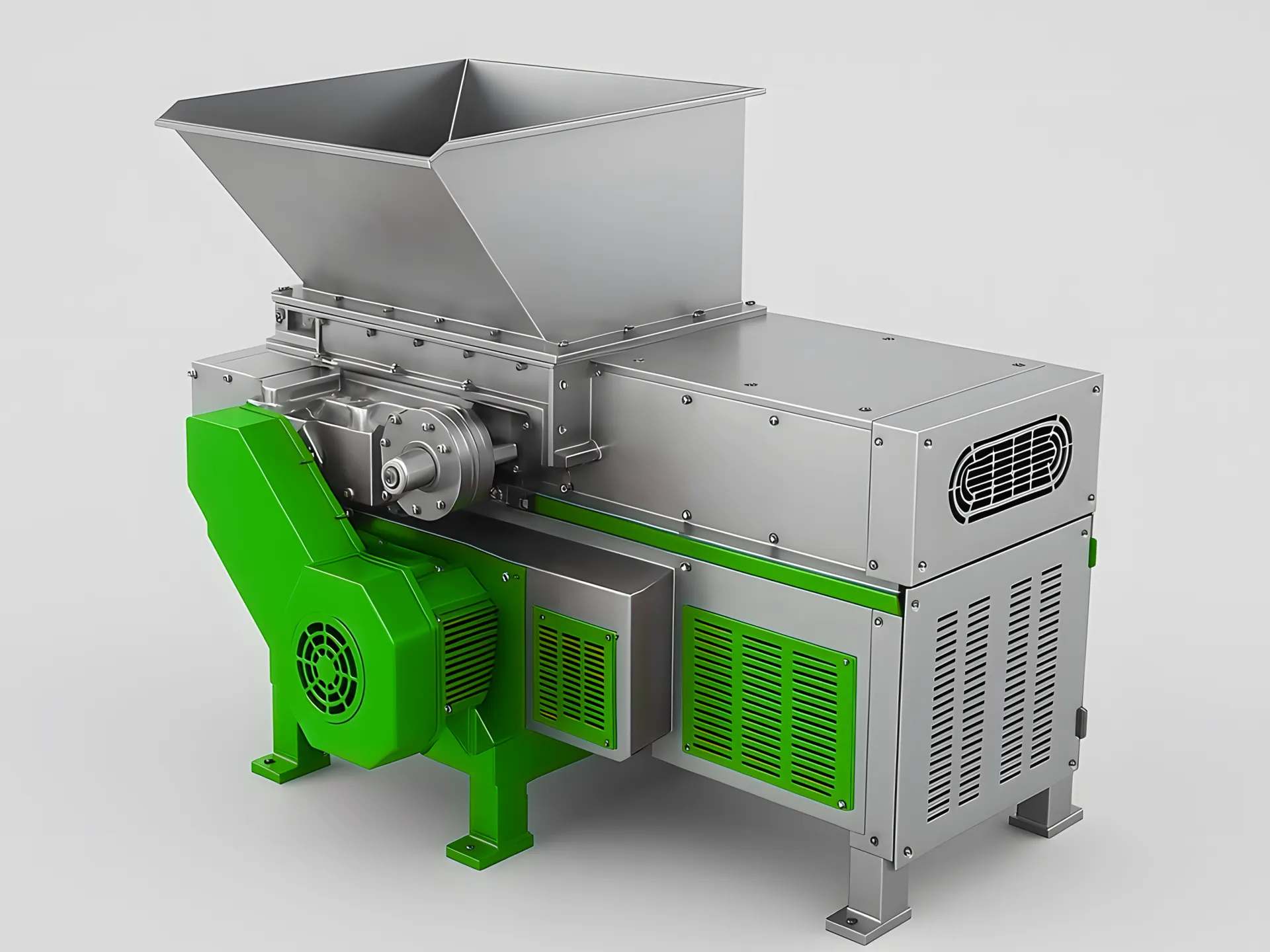

Tocător standard cu un singur arbore

Tocător standard cu un singur arbore Un tocător cu un singur rotor, alimentat de cilindru, cu design dovedit, construit pentru reducerea controlată a dimensiunii materialelor plastice rigide, lemnului, paleților și deșeurilor de producție - ideal atunci când aveți nevoie de un randament constant pentru...