Máquina de moagem de disco de plástico totalmente automática: moagem eficiente de pellets de plástico de PVC em pó de malha 20-100

O que são máquinas de moagem de plástico?

Máquinas de moagem de plástico são ferramentas essenciais para moer e processar materiais plásticos. Essas máquinas são uma pedra angular das indústrias modernas de reciclagem e fabricação de plástico.

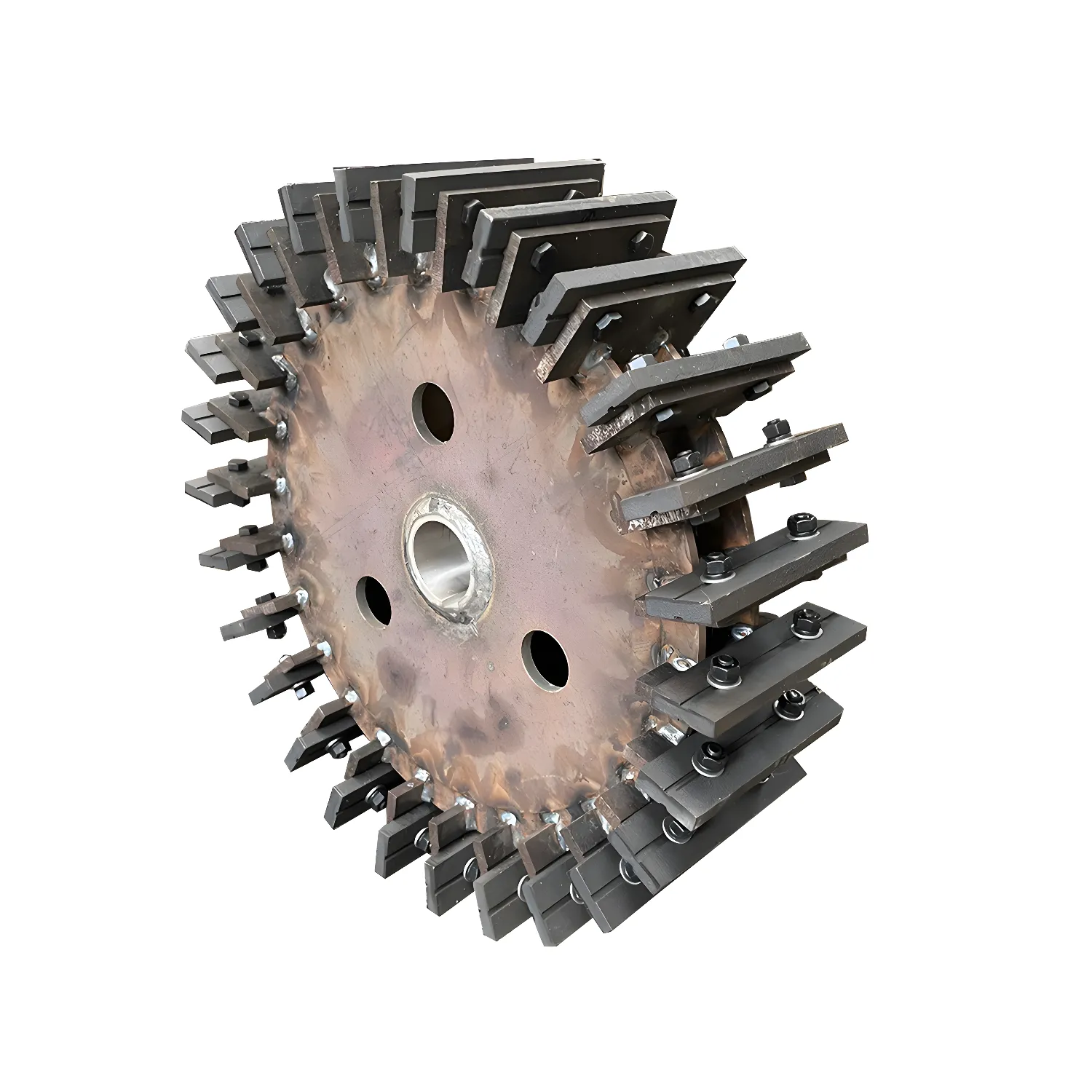

- Máquinas de retificação de disco: Opera moendo e cortando materiais usando o espaço entre dois discos de moagem projetados com precisão.

Design e Desenvolvimento Avançado

Nossas máquinas de moagem de plástico são projetadas com a mais recente tecnologia, incorporando recursos avançados inspirados em equipamentos internacionais. Elas atendem às necessidades do cliente para processar uma ampla gama de materiais termoplásticos, incluindo:

- PVC

- PE de alta densidade

- PS

- SBS

- PE espumado

- EVA

- PVC macio

- Fibras vegetais

- Couro

Essas máquinas são indispensáveis para reciclar resíduos plásticos, permitindo que os fabricantes gerenciem o excesso de materiais de forma eficiente e, ao mesmo tempo, reduzam os custos de produção.

Principais vantagens das máquinas de moagem de plástico

As máquinas de moagem de plástico oferecem inúmeras vantagens, tornando-as uma escolha superior para o processamento de plástico:

- Alto rendimento: Ofereça desempenho excepcional com máxima eficiência, garantindo produção rápida.

- Baixo consumo de energia: Economize energia sem comprometer a qualidade da moagem.

- Tamanhos de malha de moagem ajustáveis: Adapte a saída às suas necessidades específicas, com controle preciso para tamanhos de partículas.

- Manutenção fácil: Simplifique a manutenção com recursos de design fáceis de usar que reduzem o tempo de inatividade.

- Operação ecologicamente correta: Essas máquinas são projetadas para operar sem causar poluição, apoiando práticas de fabricação sustentáveis.

Em comparação com equipamentos similares, as máquinas de moagem de plástico oferecem desempenho aprimorado, atendendo às necessidades práticas do usuário e promovendo operações econômicas e ecologicamente corretas.

Parâmetros técnicos

| Modelo | Poder | Diâmetro de rotação | Potência do ventilador | Número de lâminas | Diâmetro da tela de vibração | Produção | Peso do equipamento |

|---|---|---|---|---|---|---|---|

| MF-500 | 2,2 kW | 500 milímetros | 4 kW | 12 + 24 | 800 milímetros | 150–200 kg/h | 1500 KG |

| MF-600 | 4 kW | 600 milímetros | 5,5 kW | 13 + 26 | 1000 milímetros | 200–450 kg/h | 2000 KG |

| MF-800 | 4 kW | 800 milímetros | 11 kW | 15 + 32 | 1200 milímetros | 500–800 kg/h | 2800 KG |