Recycling and processing PVC (polyvinyl chloride) is crucial for sustainability and cost-effectiveness. But when it comes to breaking down PVC waste, you’re faced with a key decision: Retificação de PVC ou Trituração de PVC? Esta escolha, aparentemente simples, pode ter um impacto significativo na qualidade do seu produto final, na sua eficiência operacional e na sua rentabilidade global. Este artigo aprofunda as diferenças entre estes dois métodos, ajudando-o a fazer a escolha certa. melhor escolha para seu specific PVC processing needs. Whether you’re dealing with rigid PVC pipes, flexible PVC films, or post-consumer PVC waste, understanding these distinctions is essential.

Understanding the Core Differences: Particle Size and Application

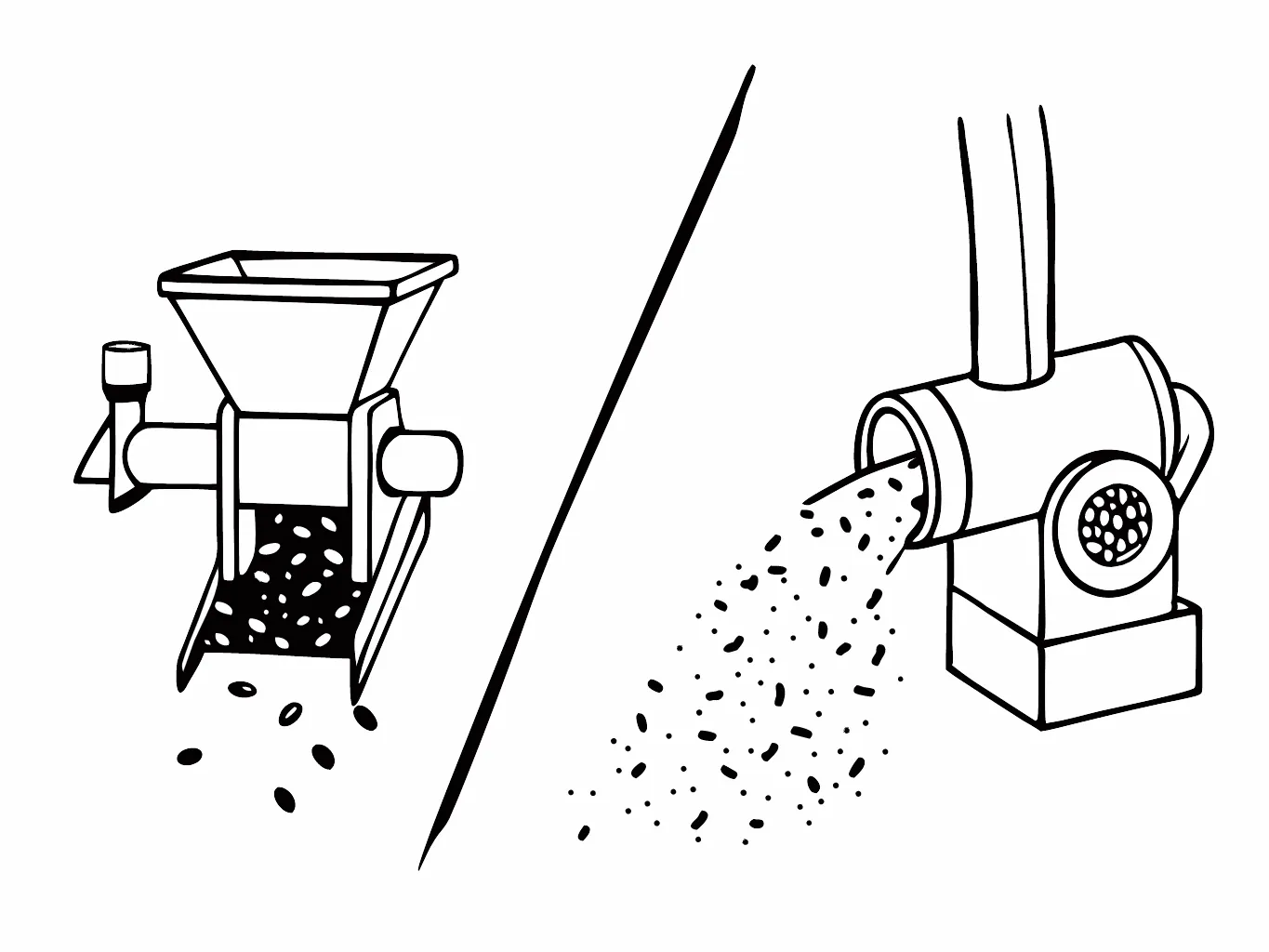

The fundamental difference lies in the output.

- Crushing: Crushing primarily reduces the size of PVC waste into larger, irregular chunks. Think of it as the first step in the size reduction process. It’s like breaking a large rock into smaller stones.

- Grinding: Grinding takes the process further, reducing the PVC into a much finer, more uniform powder ou granulate. This is akin to turning those smaller stones into sand or fine gravel.

This difference in particle size dictates the appropriate applications for each method.

PVC Crushing: The Initial Breakdown

What it is: PVC crushing utilizes heavy-duty machinery, often jaw crushers, impact crushers, or cone crushers, to apply compressive force to break down large PVC pieces.

Best for:

- Pre-processing: Crushing is almost always the first step in PVC recycling, especially for bulky items like pipes, profiles, and window frames.

- Handling large, rigid PVC: Crushers are designed to handle tough, thick materials that would overwhelm a grinder.

- Reducing volume for transport: Crushed PVC takes up significantly less space than whole pieces, making transportation more economical.

- Preparing material for further processing: Crushed PVC is the ideal feedstock for subsequent grinding.

Limitações:

- Non-uniform particle size: The resulting material is inconsistent in size and shape.

- Not suitable for direct use in many applications: The large, irregular chunks are rarely usable in manufacturing without further processing.

- Potential for contamination: If the PVC isn’t properly cleaned before crushing, contaminants can become embedded in the material.

PVC Grinding: Achieving Fine Granulation

What it is: PVC grinding employs specialized grinders, often knife grinders, hammer mills, or pulverizers, to reduce crushed PVC into a fine, consistent powder or granulate.

Best for:

- Creating usable PVC regrind: The primary goal of grinding is to produce a material that can be directly re-introduced into the manufacturing process.

- Achieving specific particle size requirements: Grinders can be adjusted to produce different particle sizes, depending on the needs of the application (e.g., fine powder for extrusion, coarser granules for injection molding).

- Improving material homogeneity: Grinding ensures a uniform particle size distribution, which is crucial for consistent product quality.

- Producing material of high value: The fine result can be sold or reused.

Limitações:

- Requires pre-crushed material: Grinders typically cannot handle large, bulky PVC pieces.

- Higher energy consumption: Grinding generally requires more energy than crushing.

- Potential for heat buildup: Friction during grinding can generate heat, which can degrade the PVC if not properly managed (cooling systems are often used).

- Maintenance requirements: Grinder blades or hammers require regular sharpening or replacement.

Choosing the Right Process: A Step-by-Step Guide

Here’s a practical guide to help you decide:

- Assess your PVC waste: What type of PVC are you processing (rigid, flexible, mixed)? What is its size and shape? What are the contaminants?

- Define your end-product requirements: What particle size and quality do you need? Will the processed PVC be used internally or sold?

- Consider your budget and capacity: What is your budget for equipment and operating costs? What volume of PVC do you need to process?

- Prioritize pre-processing: If you’re dealing with large, rigid PVC, crushing is almost certainly necessary.

- Focus on grinding for final product: If you need a fine, uniform PVC regrind, grinding is essential.

- Think about integration: The most efficient PVC processing systems often combine crushing and grinding in a sequential process.

- Perform testing: It is highly recommended to submit samples of the PVC waste to specialized companies.

Key Considerations for Both Processes

- Controlo de poeiras: Both crushing and grinding can generate significant amounts of PVC dust, which is a health and safety hazard. Effective dust collection systems are essential.

- Metal Separation: PVC waste often contains metal contaminants (e.g., screws, fasteners). Magnetic separators should be used before crushing and grinding to prevent damage to the equipment and ensure the purity of the final product.

- Material Handling: Efficient material handling systems (e.g., conveyors, feeders) are crucial for optimizing the throughput and minimizing manual labor.

- Maintenance: Regular maintenance, including lubrication, blade sharpening/replacement, and inspection, is vital for the longevity and performance of both crushers and grinders.

The Future of PVC Recycling: Advanced Technologies

While crushing and grinding remain the core of PVC size reduction, advancements are constantly being made. These include:

- Cryogenic Grinding: Using liquid nitrogen to cool the PVC to extremely low temperatures, making it brittle and easier to grind into a very fine powder. This minimizes heat degradation.

- Advanced Sorting Technologies: Using sensors and other technologies to automatically sort different types of PVC and remove contaminants with greater precision.

- Chemical Recycling: Breaking down PVC into its constituent chemicals, which can then be used to create new PVC or other products. (This is a longer-term trend, but important to mention).

Conclusão:

Choosing between PVC grinding and crushing isn’t an either/or proposition. It’s about understanding the role of each process in achieving your specific goals. For most PVC recycling and processing operations, a combination of crushing and grinding, along with proper material handling and dust control, is the most effective approach. By carefully considering your needs and investing in the right equipment, you can maximize the value of your PVC waste and contribute to a more sustainable future.

Ready to optimize your PVC processing? Contact us today for a free consultation and let us help you find the perfect crushing and grinding solution for your business!