Understanding the intricacies of a Single Shaft Shredder can be crucial for those operating in recycling or waste management industries. This type of shredder plays a pivotal role in the size reduction of various materials, making its components integral to its function. Let’s delve into the key components that define its efficiency and effectiveness.

The Importance of the Rotor in a Single Shaft Shredder

Core Functionality:

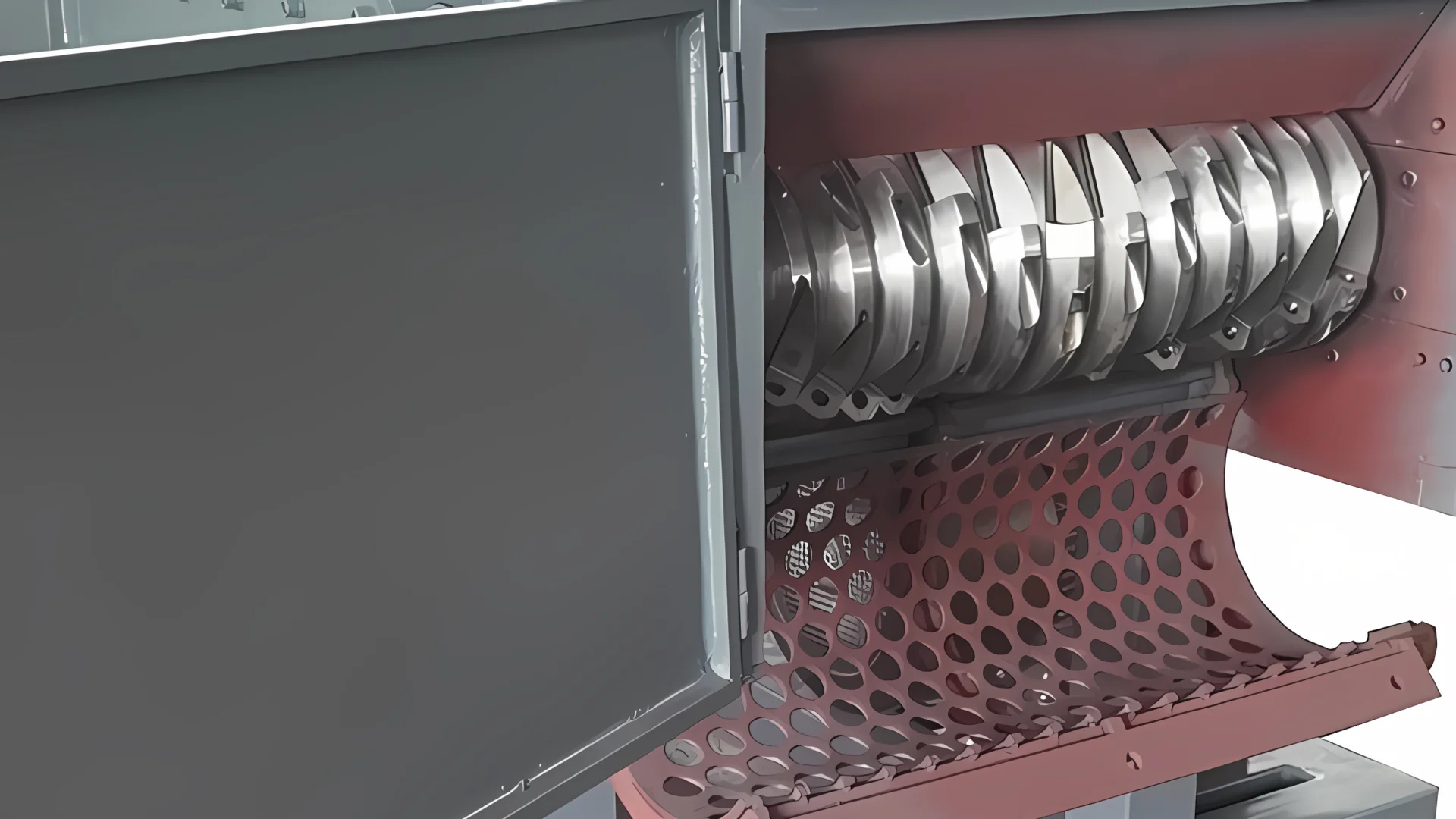

The rotor is the heart of the single shaft shredder. It is typically equipped with robust, durable blades arranged in a specific pattern to maximize the shredding process. The rotor’s design and rotational speed are critical for determining the shredder’s effectiveness in processing different materials.

Impact on Shredding Process:

- Torque and Speed: High torque at low speeds is characteristic of these rotors, allowing them to handle tough materials without excessive wear.

- Material Handling: The rotor’s configuration can also impact its ability to process varying feedstock sizes and types, from plastics to metals.

The Significance of Cutting Blades in a Single Shaft Shredder

Cutting Efficiency:

The blades are directly responsible for the shredding action. Their material, sharpness, and arrangement on the rotor affect how efficiently the shredder can cut through materials.

Contributions to Machine Efficiency:

- Material Reduction: Sharp, well-maintained blades ensure consistent material size reduction, which is crucial for subsequent recycling processes.

- Wear and Tear: Blade quality also impacts the frequency of maintenance and replacement, affecting overall operational costs.

The Role of the Hydraulic System in a Single Shaft Shredder

Control and Flexibility:

The hydraulic system in a single shaft shredder offers enhanced control over the shredding process. It allows for the adjustment of pressure and speed based on the material being processed, which is vital for preventing jams and optimizing throughput.

Benefits of Hydraulic Control:

- Process Adjustment: Operators can fine-tune the shredding action, adapting to different materials on the fly.

- Maintenance and Safety: Hydraulics facilitate easier access to the shredder’s internal components for maintenance and provide safety mechanisms to protect the machine and operators during operation.

Understanding these key components—the rotor, cutting blades, and hydraulic system—provides insight into the operational capabilities and efficiencies of a Single Shaft Shredder. Each component is crucial for ensuring that the shredder performs optimally, adapting to various materials and operational demands. By recognizing the importance of these components, operators can better maintain their equipment, extend its lifespan, and optimize its performance for their specific shredding needs.