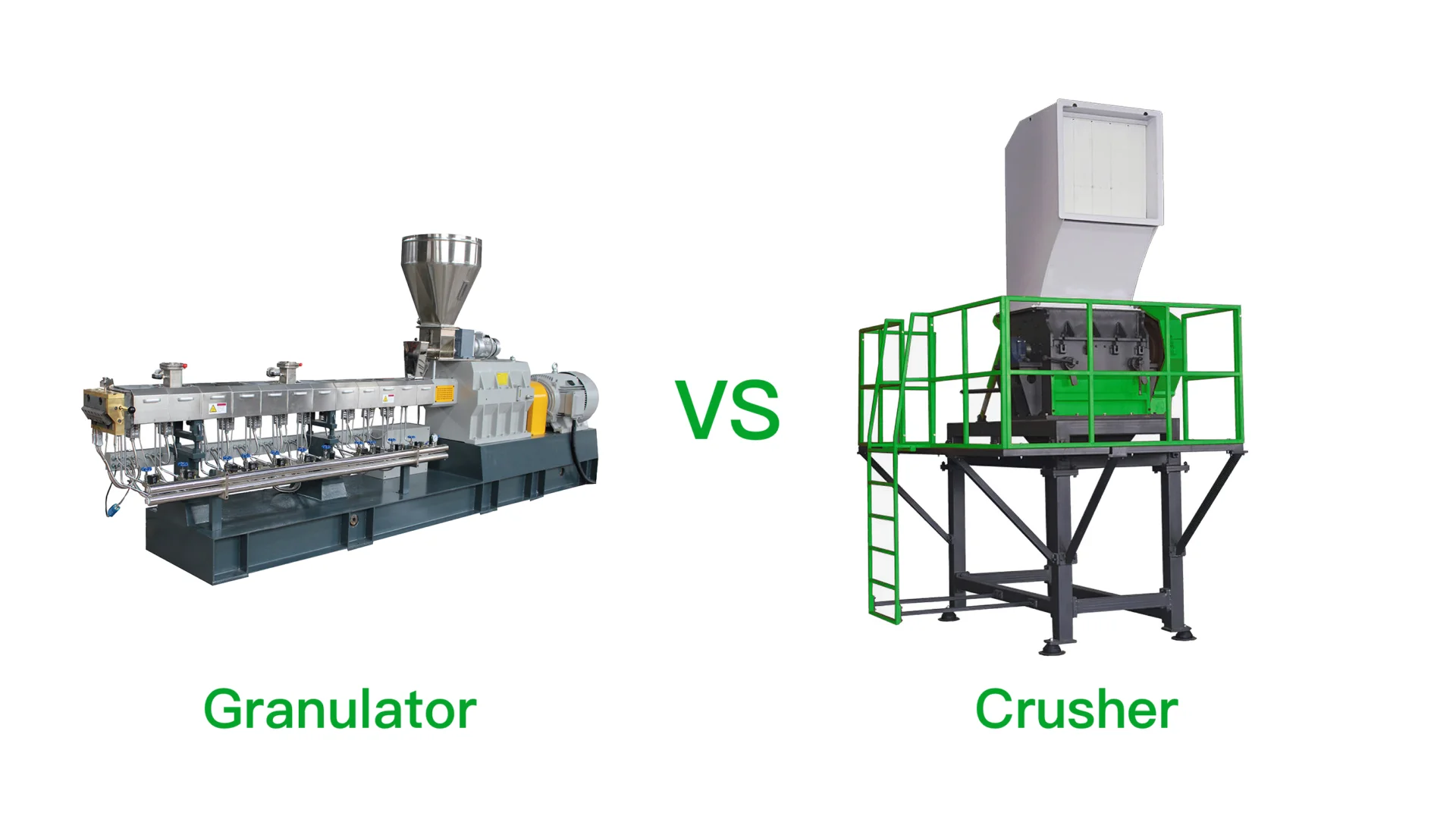

Unveiling the Essentials: Plastic Granulators vs Plastic Crushers

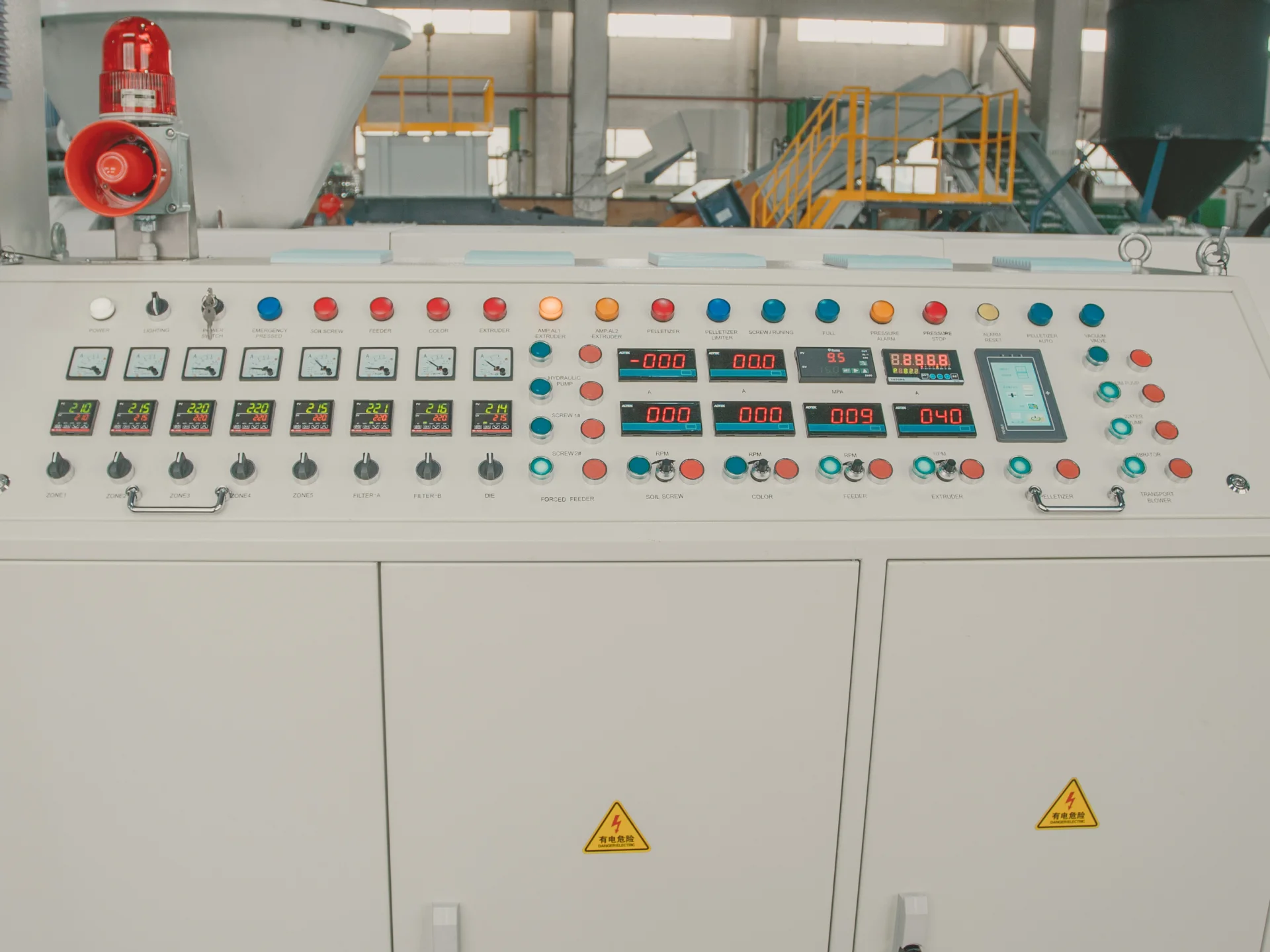

Decoding the Crucial Tools in Recycling Operations In the fast-paced world of recycling, where efficiency meets innovation, the spotlight often lands on two heavyweight champions: plastic granulators and plastic crushers. As th...