Sustainable Cleanliness: Eco-Friendly Recycling Washing Solutions

Recycling Washing Systems

Clean Cycle: Advanced Recycling Washing Systems

Wash & Reuse: Maximize Recycling with Our Systems

Pollution Fighters: Washing for a Cleaner Future

Categories PET Bottle Recycling Washing Line

Posted on

Categories Plastic Recycling washing line

Posted on

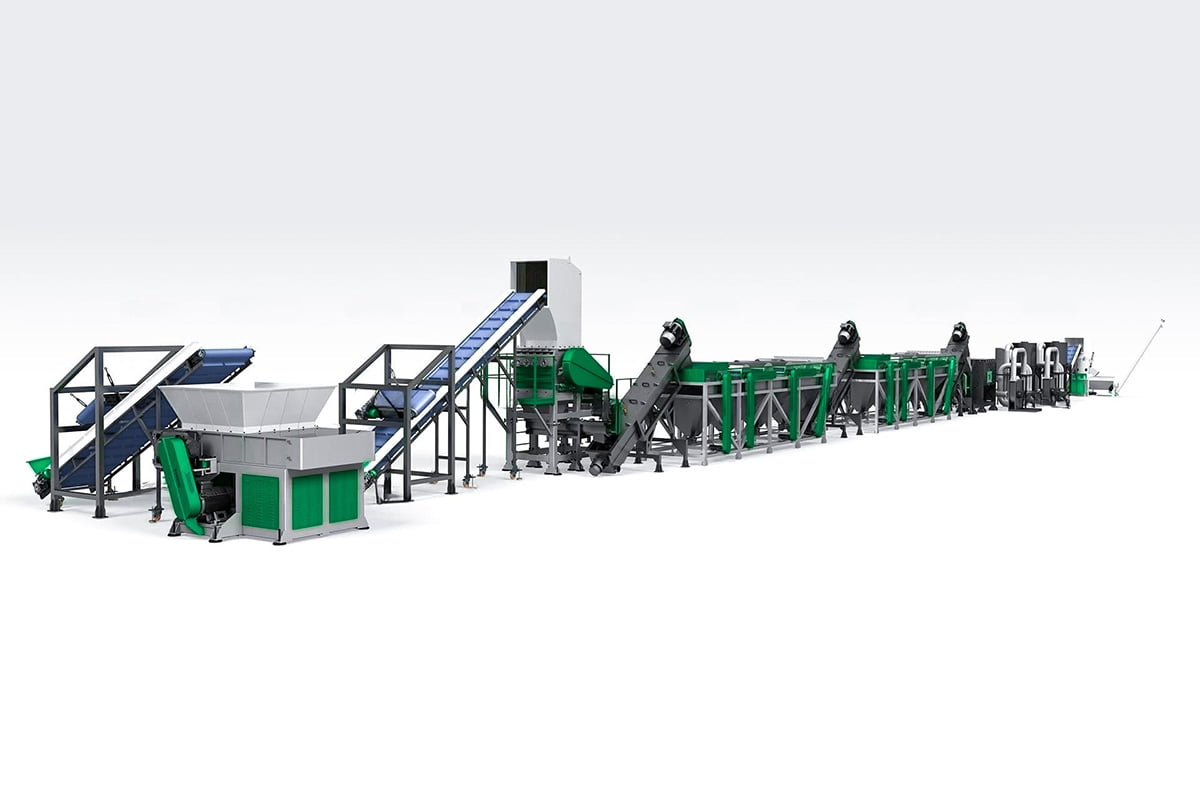

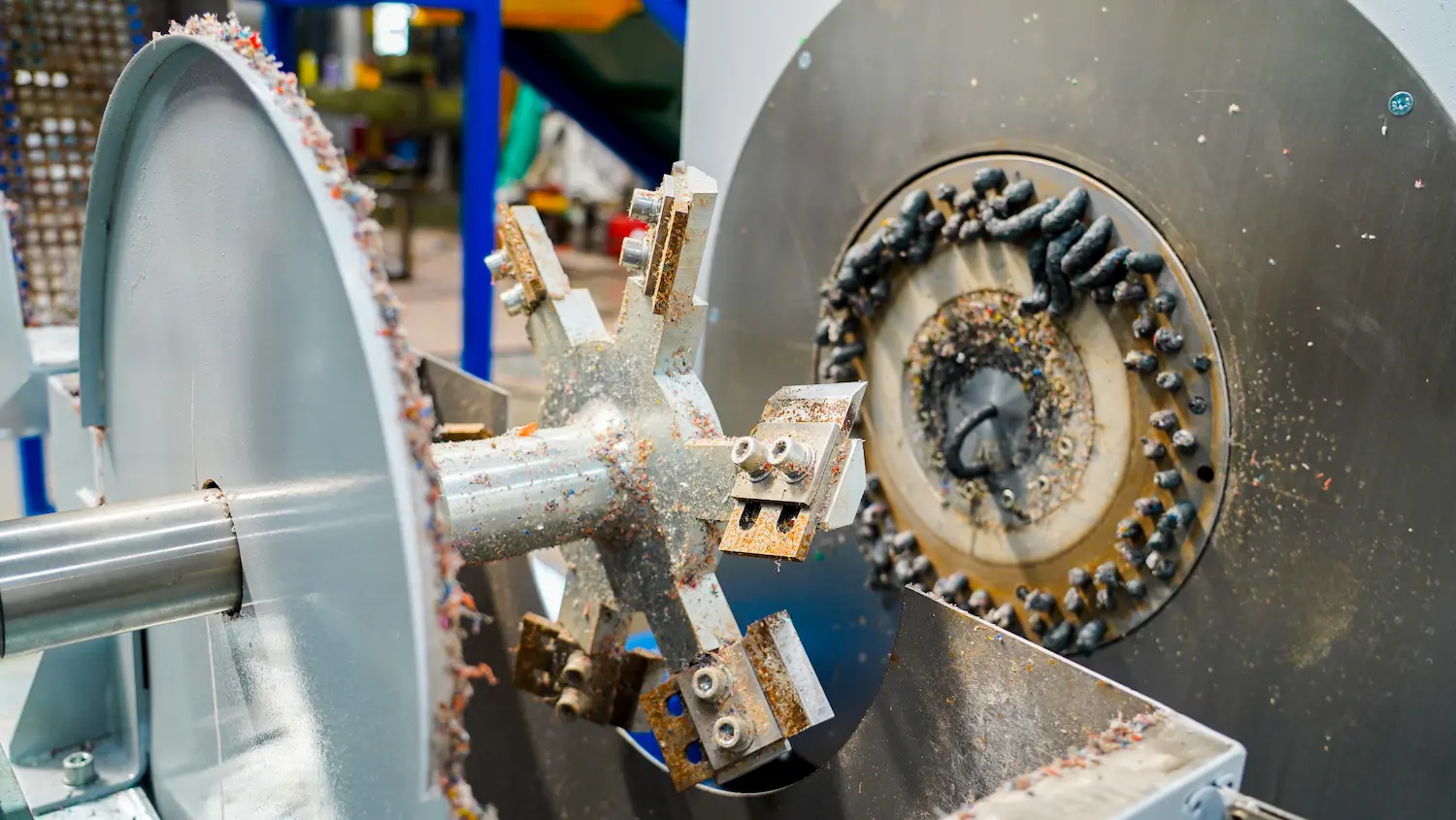

The entire line is designed to clean shredded PP/PE regrind, featuring a friction washer, floatation tank, centrifugal dryer, squeezer, extruders, and pellet cutting system. Below are explanations for some of the key machines:

Categories Plastic Recycling washing line

Posted on

Categories Plastic Recycling washing line

Posted on

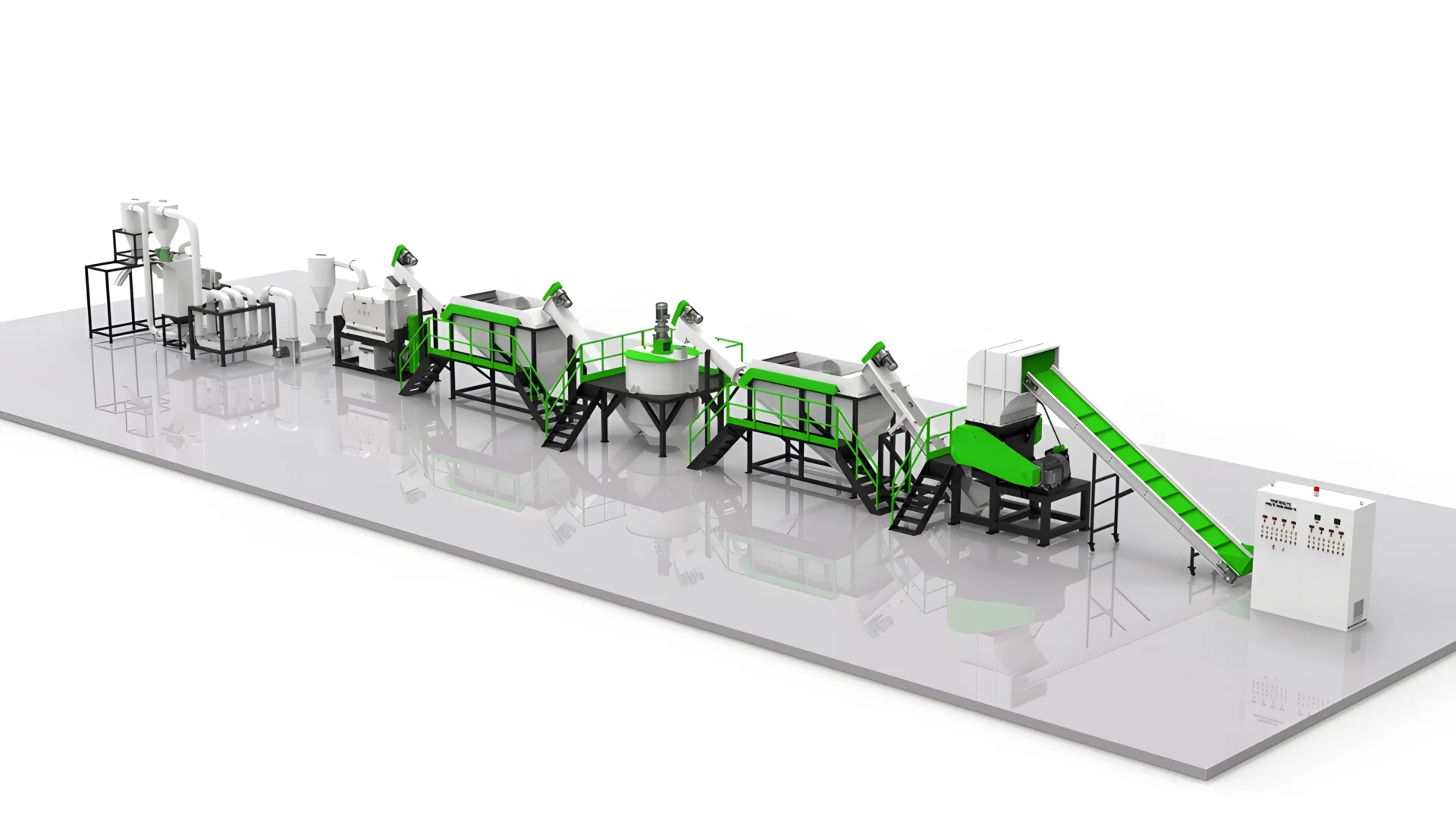

Explore the cutting-edge HDPE and PP Rigid Plastic Shredding Recycling Line, designed to transform bulky HDPE and PP materials into high-quality reusable pellets. Our advanced recycling line ensures efficient processing, from shredding to pelletizing, to support your environmental sustainability goals.

Categories Plastic Recycling washing line

Posted on

This article comprehensively introduces key equipment and processes in plastic film washing lines, including shredding, washing, separation, and drying stages. It compares the pros and cons of shredders and crushers in detail, and analyzes the working principles of washing equipment such as high-speed friction washers and floating tanks. The article also discusses how to customize washing lines based on raw material characteristics and production requirements, providing practical technical guidance and equipment selection advice for plastic recycling enterprises.

Categories PET Bottle Recycling Washing Line

Posted on

Explore the advanced features and technical specifications of our PET Washing Line. Turn waste PET bottles into high-quality, eco-friendly flakes with ease.

Categories Plastic Recycling washing line

Posted on

The PP PE film shredding and densifying line represents a breakthrough in plastic recycling technology. This innovative system efficiently processes dirty bales of PP/PE films through a four-stage process: shredding, wet granulation, sink/float separation, and densification. By transforming waste plastic films into high-density pellets, this technology not only enhances recycling efficiency but also contributes significantly to environmental preservation and the circular economy of plastics. With customizable options and the ability to increase material density up to 410 kg/m3, it offers a versatile solution for modern recycling challenges.

Categories Plastic Recycling washing line

Posted on

Discover the Innovative PP PE Plastic Film Shredding and Densifying Line, a complete solution for transforming dirty PP/PE films into densified products ready for further processing.

Categories PET Bottle Recycling Washing Line

Posted on

Discover the PET Bottle Washing Line with a capacity of 500 kg/h. A comprehensive, turnkey solution for transforming waste PET bottles into clean, reusable flakes.

Categories Plastic Recycling washing line

Posted on

Discover PP/PE Film Washing Lines, a turnkey solution for plastic film recycling. Transform dirty PP and PE films into high-quality, market-ready pellets.